15.12.2021

Optimisation in mould making

Flexibility and productivity with solid carbide tools

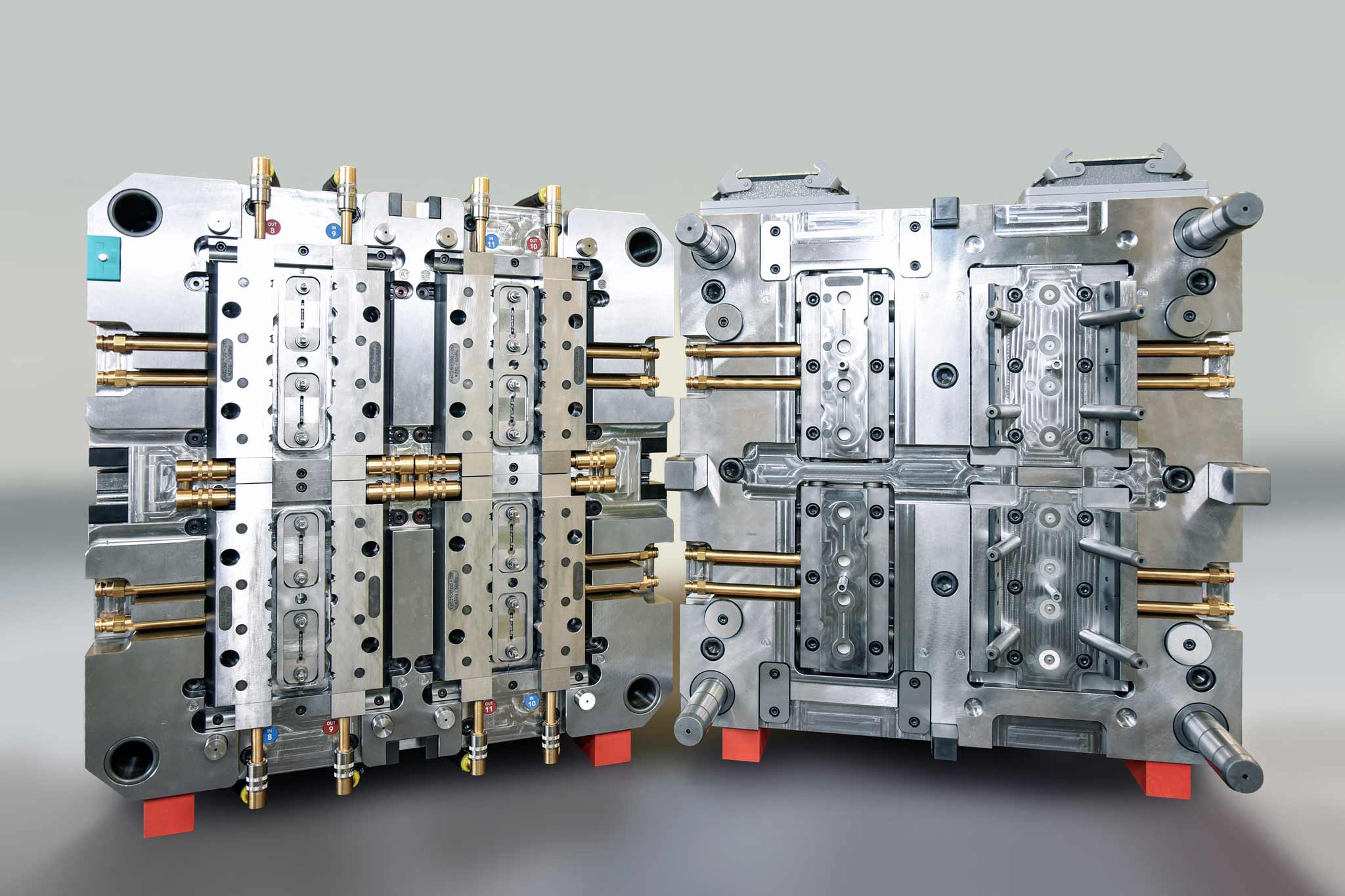

In the space of six years, Marco Schülken has thoroughly transformed the Thuringian toolmaking company he took over in 2015. With his 30 employees, he was able to attract customers in various sectors and enter new markets, including the ones abroad. MAPAL came into play when looking at optimising production processes.

Die Vorgängerfirma Ralf Grübel Werkzeugbau GmbH war ein inhabergeführtes Unternehmen in dritter Generation aus Waltershausen/Thüringen, das Marco Schülken im Rahmen einer geregelten Altersnachfolge übernehmen konnte. Schon mit dem in Schülken Form GmbH geänderten Firmennamen machte der neue Inhaber deutlich, dass mit einer neuen Marke auch ein frischer Wind in dieses alteingesessene Unternehmen des Werkzeug- und Formenbaus kommen soll.

Lieferte Grübel seine Produkte noch zu über 90 Prozent in die Automobilindustrie, so ist es Schülken gelungen, diese einseitige Ausrichtung aufzubrechen. Der Automobilanteil liegt aktuell bei unter 25 Prozent. Ihr Hauptgeschäft macht die Schülken Form heute mit Unternehmen aus der Medizintechnik und der Verpackungsindustrie. Im Medizinbereich sind die Thüringer stark bei Spritzgusswerkzeugen für Pipetten und Blutlanzetten. Die Lanzetten sind Stechhilfen für Diabetiker, werden jetzt aber auch für Covid-Tests genutzt.

Alles auf dem Prüfstand

Neben der Ausrichtung auf neue Märkte wurde bei Schülken Form auch innerbetrieblich gründlich umstrukturiert. „Wir haben im Haus nahezu jede Maschine und jeden Prozess angefasst und dabei sehr viel investiert“ berichtet der Geschäftsführer. Bei diesem Umstrukturierungsprozess war von Anfang an Fertigungsleiter Marcus Vogt mit dabei, den ständig die Frage umtreibt, wie die Performance im Unternehmen weiter verbessert werden kann. Zwar gebe es auch beim Drahterodieren oder Senkerodieren immer wieder mal etwas Neues, aber das Fräsen sei die schnelllebigste Bearbeitungstechnologie. „Man muss hier ständig schauen, womit man etwas verändern und verbessern kann“, so Vogt.

Schon die Firma Grübel hatte hier auf gute Maschinen Wert gelegt und setzte zum Fräsen ausschließlich Bearbeitungszentren von Hermle ein. Allerdings arbeitete dieser klassische Werkzeugbau noch eher wie ein Handwerksbetrieb. Ihre Programme haben die Mitarbeiter selbst direkt an den Maschinen erstellt. Vogt sah hier dringenden Handlungsbedarf: „Bevor wir an die Fräswerkzeuge herangegangen sind, haben wir die ganze Prozesskette überarbeitet. Wir haben Programmierarbeitsplätze eingerichtet und die komplette Fertigung auf ein neues System umgestellt.“

Hartfräsen macht flexibel

Im nächsten Schritt ging es an die eigentliche Technologie mit der Kernfrage, wie die Bauteile am besten bearbeitet werden können. „Der klassische Weg im Werkzeugbau ist ja entweder das Vorfräsen, Härten und anschließende Schleifen oder das Senkerodieren“, beschreibt Vogt die Ausgangssituation. Um die Produktion je nach Fertigungsauslastung flexibler gestalten zu können, hat Schülken das Hartfräsen hinzugenommen. Zwar werden in Waltershausen nach wie vor auch Teile nach der klassischen Methode hergestellt, doch vor allem wenn es schnell gehen muss, ist es auch kein Problem mehr, gleich nach dem Härten mit dem Fräsen zu beginnen. „Heute sind wir so weit, dass wir viele Bearbeitungen nach der Auslastung der einzelnen Abteilungen auswählen können“, freut sich Marcus Vogt.

Damit waren die Optimierungsmaßnahmen noch nicht am Ende. Als Schülken Form nach neuen Fräswerkzeugen für das Hochvorschubschruppen Ausschau hielt, war das etwa die Zeit, als sich MAPAL den Werkzeug- und Formenbau als Markt zu erschließen begann. Wie Schülken hatte sich auch der Präzisionswerkzeughersteller aus Aalen das Ziel gesetzt, durch die Hinzunahme weiterer Branchen die Abhängigkeit vom Automobilbau zu verringern.

Werkzeugbau im Wandel

Verglichen mit der Automobilindustrie, wo MAPAL seit vielen Jahren vor allem mit maßgeschneiderten Sonderwerkzeugen für große Stückzahlen sehr erfolgreich ist, scheinen die Anforderungen im Werkzeug- und Formenbau zunächst ganz andere zu sein. Hier geht es immer um Einzelstücke oder kleine Lose, die tunlichst mit Standardwerkzeugen bearbeitet werden sollen, damit die Betriebe damit verschiedenste Aufträge abarbeiten können. Doch hat auch im klassischen Werkzeugbau ein Wandel eingesetzt, der bei Schülken Form bereits deutlich zu erkennen ist.

„Der Weg geht hin zum Industriewerkzeugbau“, bringt es Marcus Vogt auf den Punkt. „Früher hat man nur darauf geachtet, dass ein anständiges Teil rauskommt, heute müssen wir auch auf die Zeiten schauen.“ Digitalisierung und Automatisierung ziehen auch in den Werkzeug- und Formenbau ein. Vogt plant vorab die Herstellung aller Bauteile für jede Abteilung mit einer bestimmten Zeit ein. Dabei geht es nicht um Sekunden, aber immerhin um Minuten. Um die vorgegebenen Zeiten zu erreichen, wird Prozesssicherheit immer wichtiger.

Dabei werden die zu bearbeitenden Materialien zunehmend anspruchsvoller. Üblich sind heute Edelstähle mit einem Chromanteil von 13 Prozent, was für einen erhöhten Werkzeugverschleiß sorgt. Auch die Zähigkeit neuer pulvermetallurgischer Stähle ist eine Herausforderung. Dabei sind Maßhaltigkeit und Oberflächengüte wichtige Aspekte.

Vergleich liefert eindeutige Ergebnisse

Die Messlatte lag hoch, als Schülken mit dem OptiMill-3D-HF-Hardened das erste MAPAL Werkzeug testete. Dieser Hochvorschubfräser aus Vollhartmetall eignet sich aufgrund seiner speziellen Linsenkopfgeometrie nicht nur zum Schruppen, sondern auch zum Hochglanz-Schlichten von Ebenen im Harten bis 68 HRC. Das kam den Anforderungen von Marcus Vogt entgegen: „Ein spezielles Werkzeug für eine spezielle Bearbeitung ist nichts für uns. Ich wähle immer Werkzeuge, mit denen ich mehrere Bereiche abdecken kann. Das sind genau solche Vollhartmetallwerkzeuge, mit denen ich sowohl im Harten als auch im Weichen schruppen kann.“

Die Ergebnisse mit dem VHM-Hochvorschubfräser überzeugten auf Anhieb und sorgten dafür, dass dieses Schruppwerkzeug mit seiner höheren Performance anstelle des zuvor eingesetzten Werkzeugs eines anderen Herstellers in Schülkens standardisierte Werkzeugliste aufgenommen wurde. Der Fertigungsleiter begrenzt diesen Werkzeugsatz auf 300 verschiedene Typen und hat den Anspruch, damit alle Anforderungen erfüllen zu können – und das, obwohl kein Teil ist wie das andere. „Für die entsprechenden Anwendungen nehmen wir jetzt kein anderes Werkzeug mehr als diesen Fräser von MAPAL“, sagt Vogt.

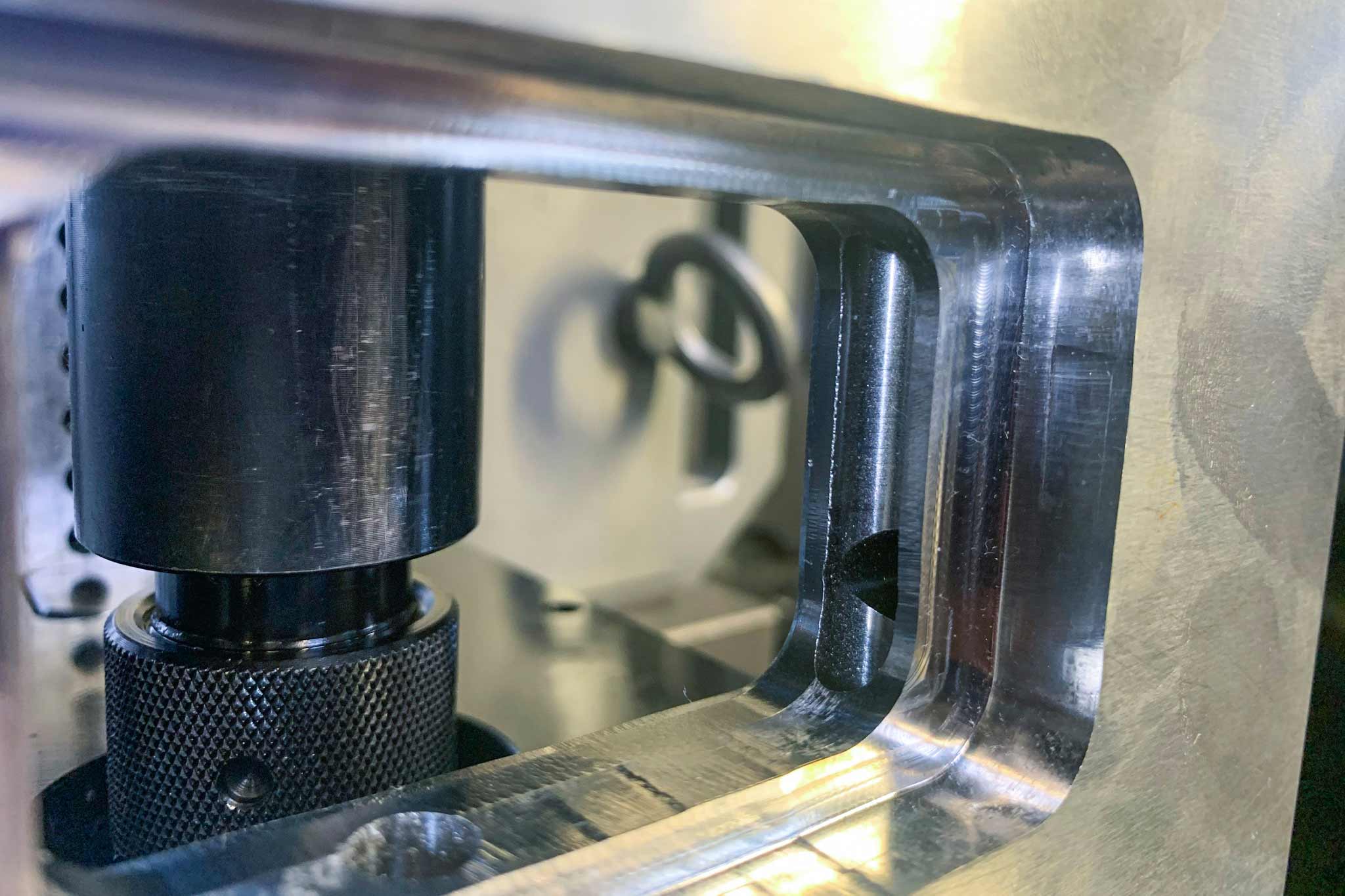

Das gilt auch für das nächste Werkzeug, das Schülken einem Vergleichstest unterzog, den Schlichtfräser OptiMill-Hardened-Finish, der bis zu 3xD ap Zustellung in einem Schnitt bis 68 HRC Flächen schlichten kann. Vogt berichtet von begeisterten Kollegen an der Maschine: Beim Schlichten von gehärtetem hochlegiertem Werkzeugstahl 1.2083 hat der Fräser mit Top-Oberflächen und hohen Standzeiten überzeugt. Mit diesem Werkzeug werden unter anderem kleine Taschen auf Passung gefräst. Nach den beiden VHM-Fräsern testet Schülken gerade einen Hochvorschubfräser mit Wendeschneidplatten, den MAPAL NeoMill-4-HiFeed90, dessen positive Schneiden einen weichen Schnitt erzeugen.

Letzte Grenze überschritten

Verfügbarkeit der Werkzeuge ist entscheidend

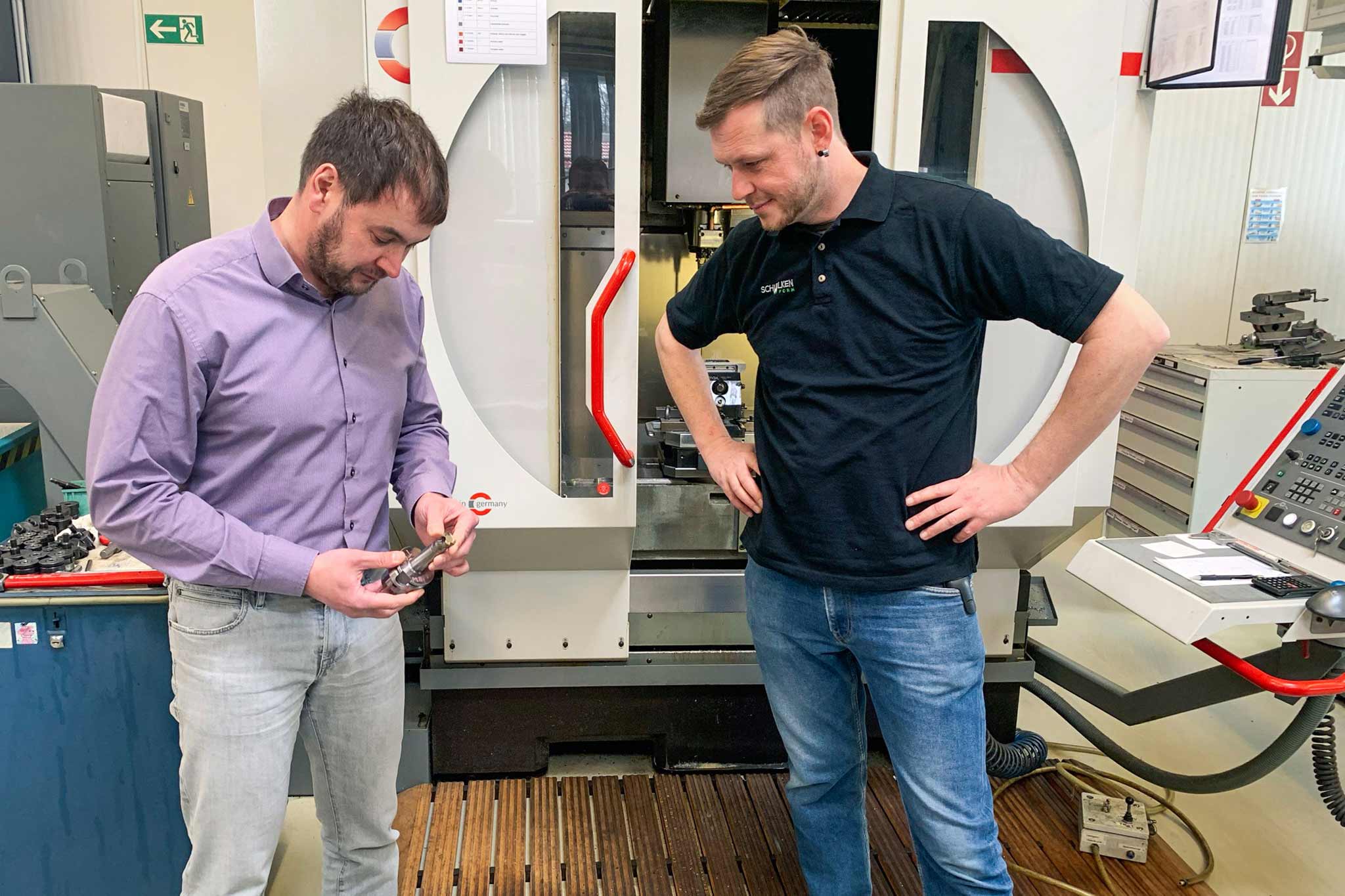

Performance verlangt Schülken nicht nur bei der Bearbeitung, wie Vogt erläutert: „Bei der Auswahl von Werkzeuglieferanten ist uns wichtig, dass die Werkzeuge sofort verfügbar sind. Und dass ich, falls mal ein Problem auftritt, einen Ansprechpartner habe, der auch weiß, wovon er redet.“ Dieser Ansprechpartner ist Produktspezialist Felix Wendler, der den Werkzeug- und Formenbau vom thüringischen MAPAL Standort Meiningen aus betreut. Ihm ist es wichtig, vor allem beim Test neuer Werkzeuge vor Ort beim Kunden zu sein: „Ich möchte gerne hören, wie das Werkzeug bei der Bearbeitung klingt, daraus lässt sich vieles schließen. Wenn ich Oberflächen sehe und fühle, kann ich sagen, was geändert werden muss, damit es besser funktioniert.“

Für zügigen Nachschub der Standardwerkzeuge sorgt das Logistikkonzept von MAPAL. Von den rund 6.500 Artikeln im Katalog für den Werkzeug- und Formenbau ist ein Großteil innerhalb von 24 Stunden verfügbar. Etwas speziellere Abmessungen können innerhalb von fünf Tagen geliefert werden. Schülken Form kommt das sehr entgegen, bleibt dem Unternehmen doch zunehmend weniger Zeit, um seine komplexen Spritzgusswerkzeuge zu fertigen.

Kontakt

Kathrin Rehor Public Relations Kathrin.Rehor@mapal.com Tel.: +49 7361 585 3342