Usinagem interna e externa da carcaça do estator

定子孔的三步解决方案

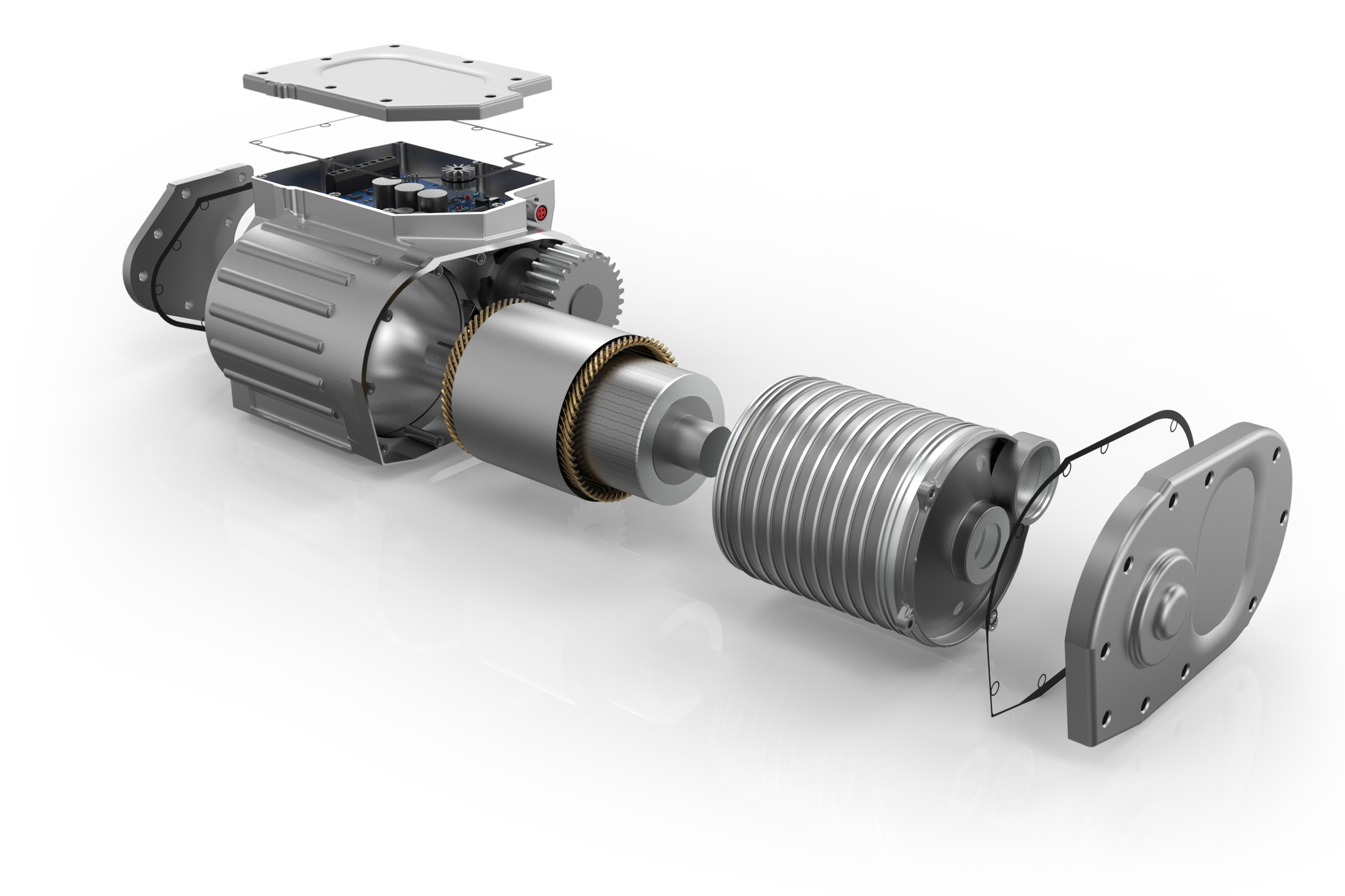

锅形的电机壳,定子壳作为中间壳被嵌入到主壳体中。薄壁铝制部件的典型内径介于200和240 mm之间,外径介于240和260 mm之间。各轴承孔和安装孔之间的同心度对电机的性能好坏是个关键,因此,需要在严苛的公差范围内实现非常精准的加工。

加工定子孔的三个工步中的第一步是使用镗刀进行粗加工。因铸件毛坯有拔模斜度,导致最大余量达6 m m。为此,使用带有圆弧支撑韧带的非标可转位刀片以避免振动。这也确保了加工所的小切屑能容易排出。在接下来的半精加工中,实现对包括倒角和过度圆弧在内 的复杂的电机壳轮廓的加工以及采用精加工刀具对工件实现微米级精度的加工。刀具可以按照工件的加工余量机床和夹具情况进行个性化设计。不同的加工部位,刀具采用的切削材料被认真考量。如铸入式或压入式的钢的轴承衬套。工件大部分加工用的是P C D刀具材料,硬质合金切削材料被用于工钢材料区域来加工。

全球首创的外径加工方案

在加工中心上实现成套加工

A usinagem interna é possível com muita rapidez e precisão com as ferramentas de mandrilamento. Além disso, o lado externo também pode ser usinado na mesma fixação, sem se mover. A solução do centro de usinagem atende aos clientes que estão adotando a transformação para e-mobilidade com o maquinário existente voltado para a usinagem de grandes caixas de alumínio.

Aqueles que começam sua produção nesse novo setor podem, certamente escolher a estratégia de usinagem que é melhor para ele. A MAPAL desenvolveu uma solução alternativa de usinagem em um projeto conjunto com um fabricante de máquinas. Nesse caso, o processo foi girado 90 graus para uso em tornos verticais.