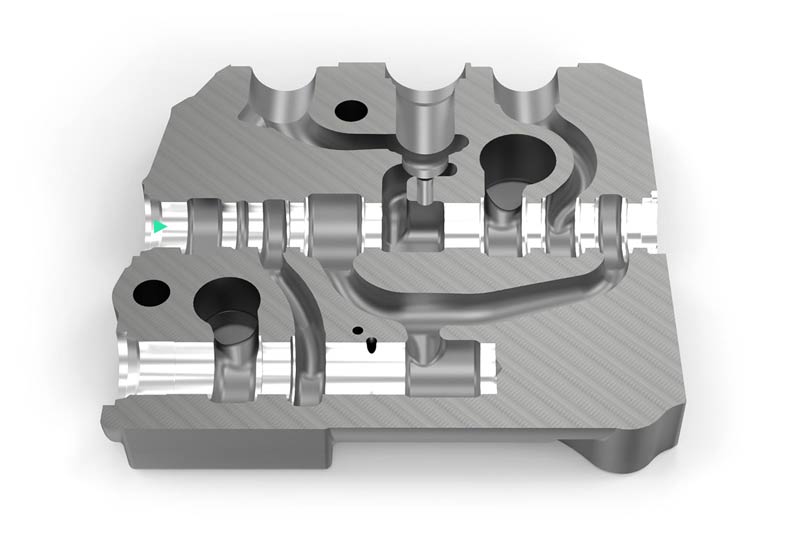

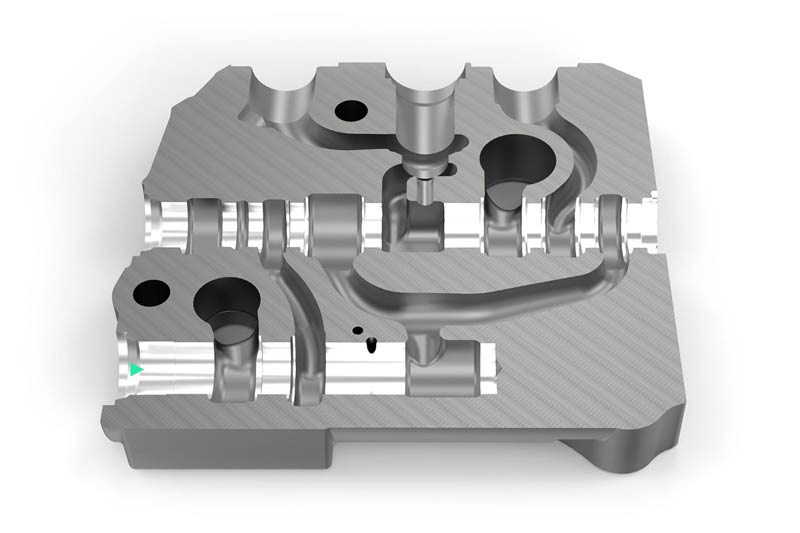

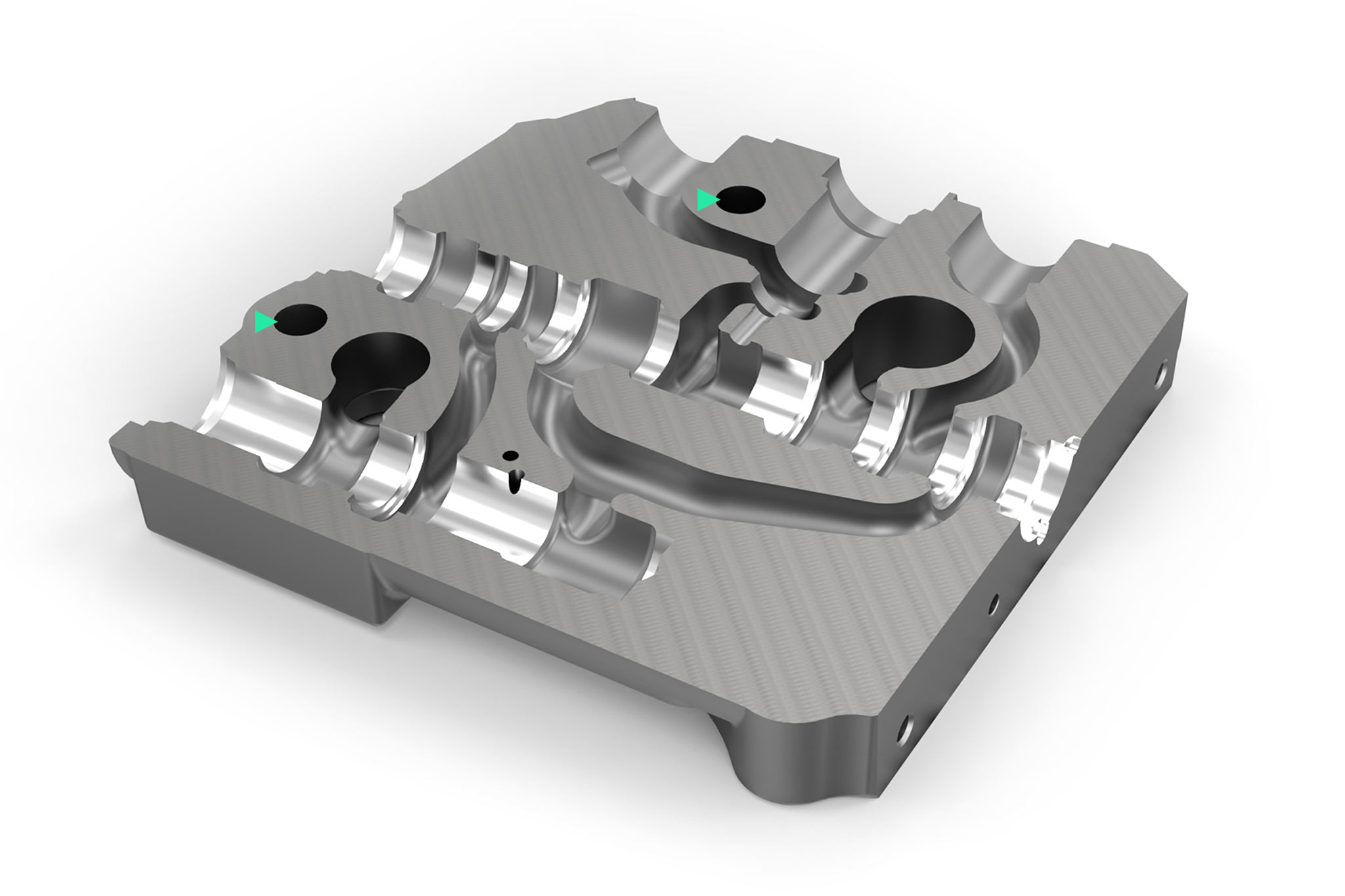

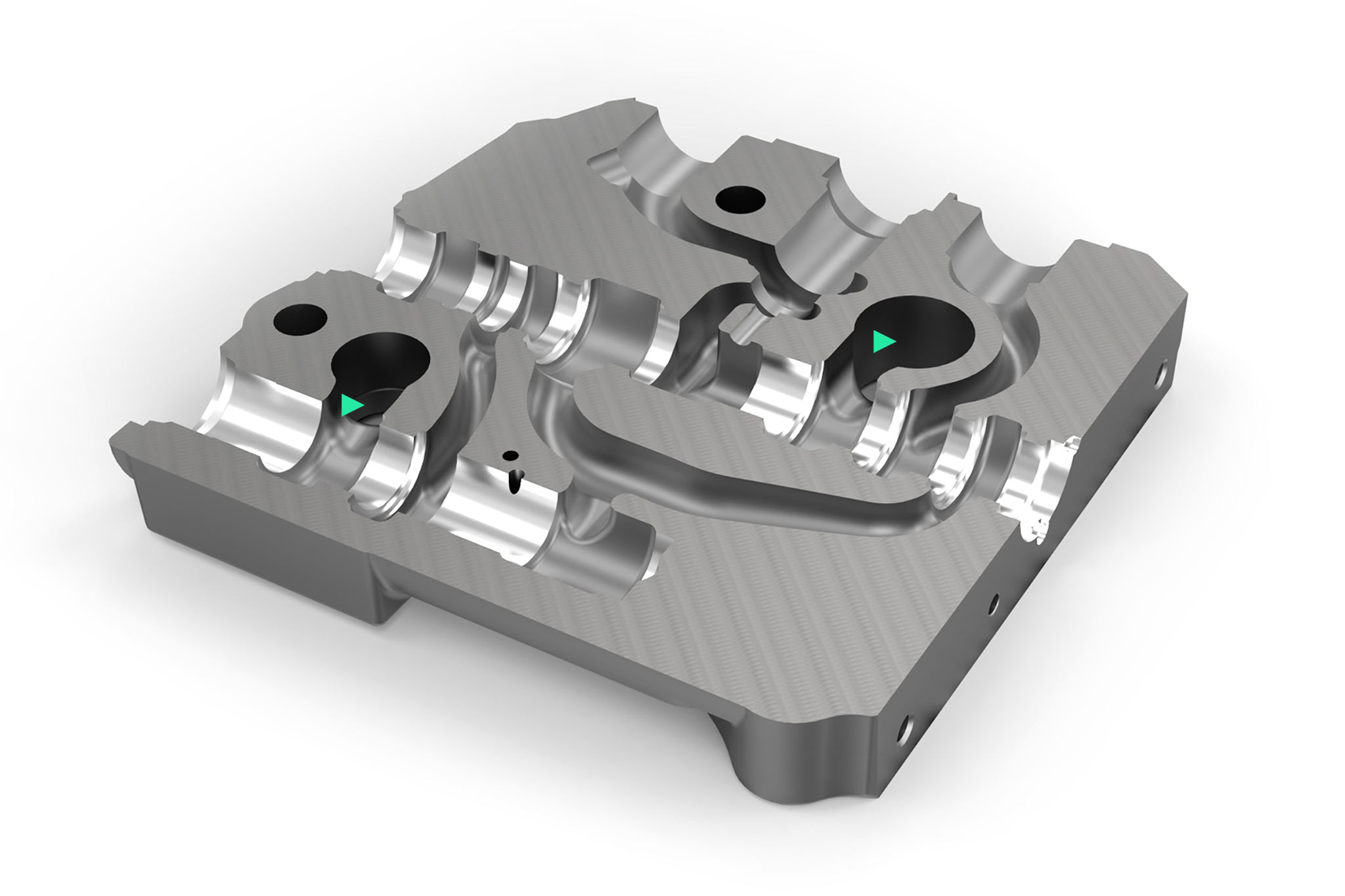

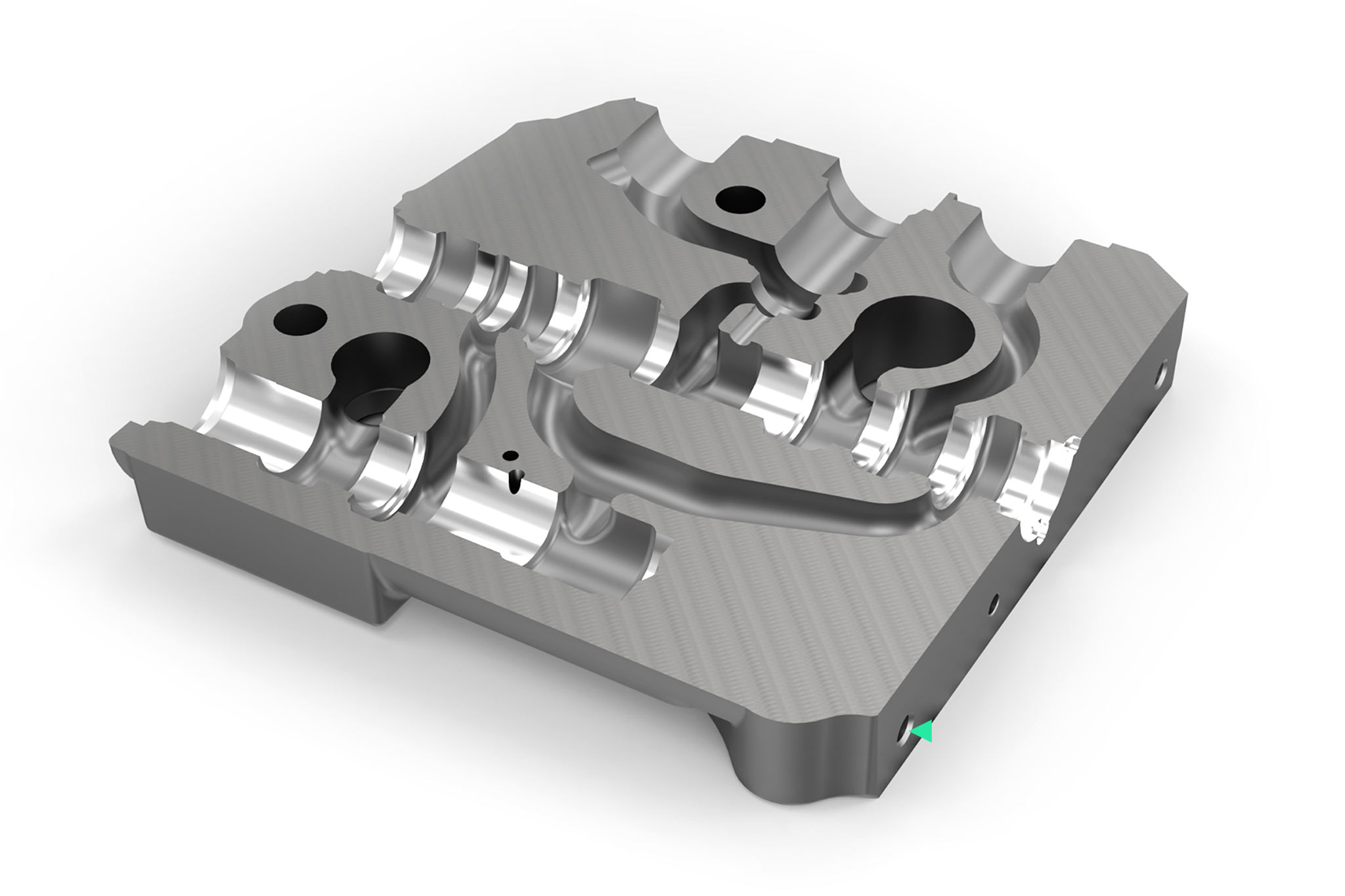

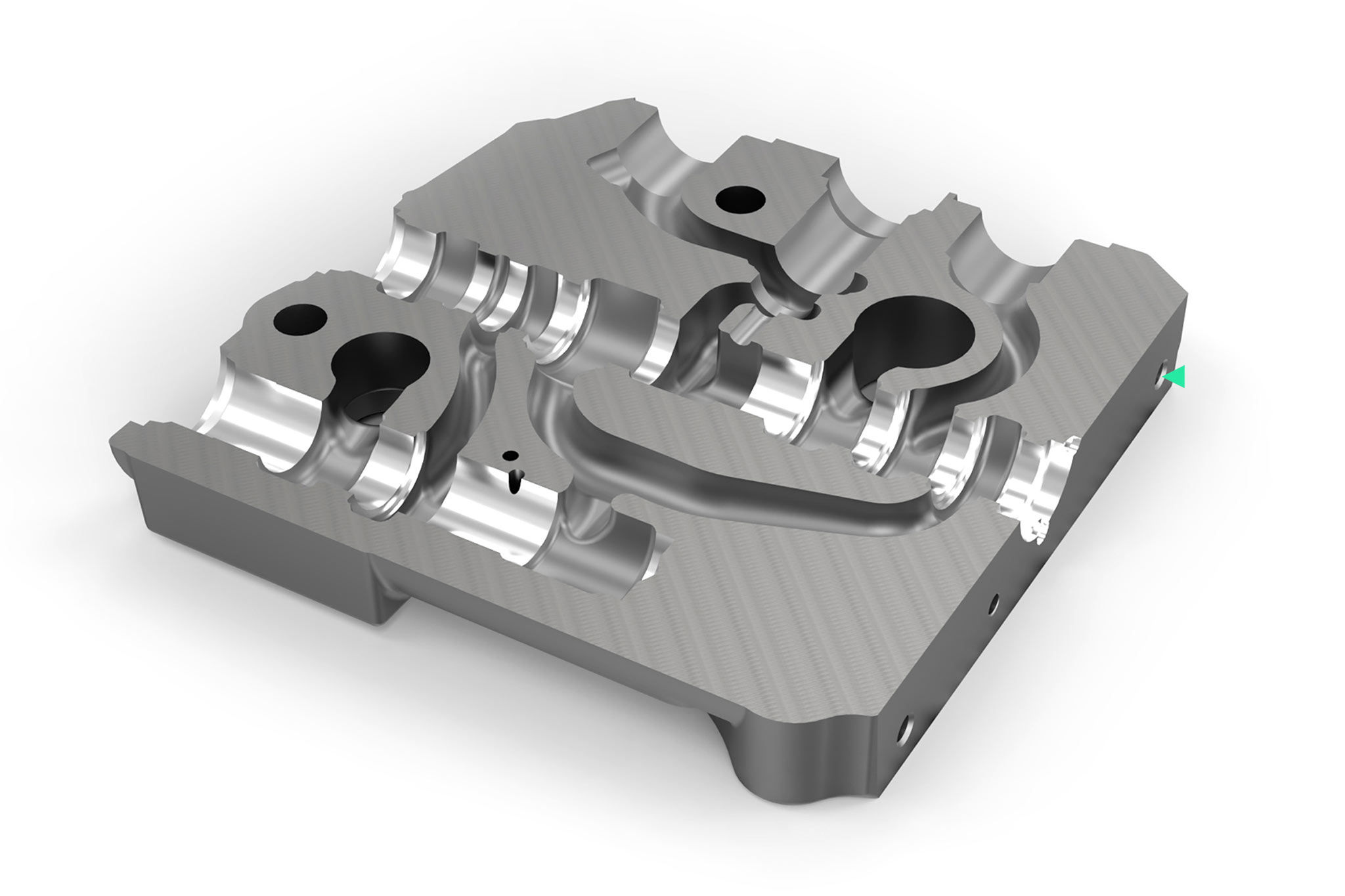

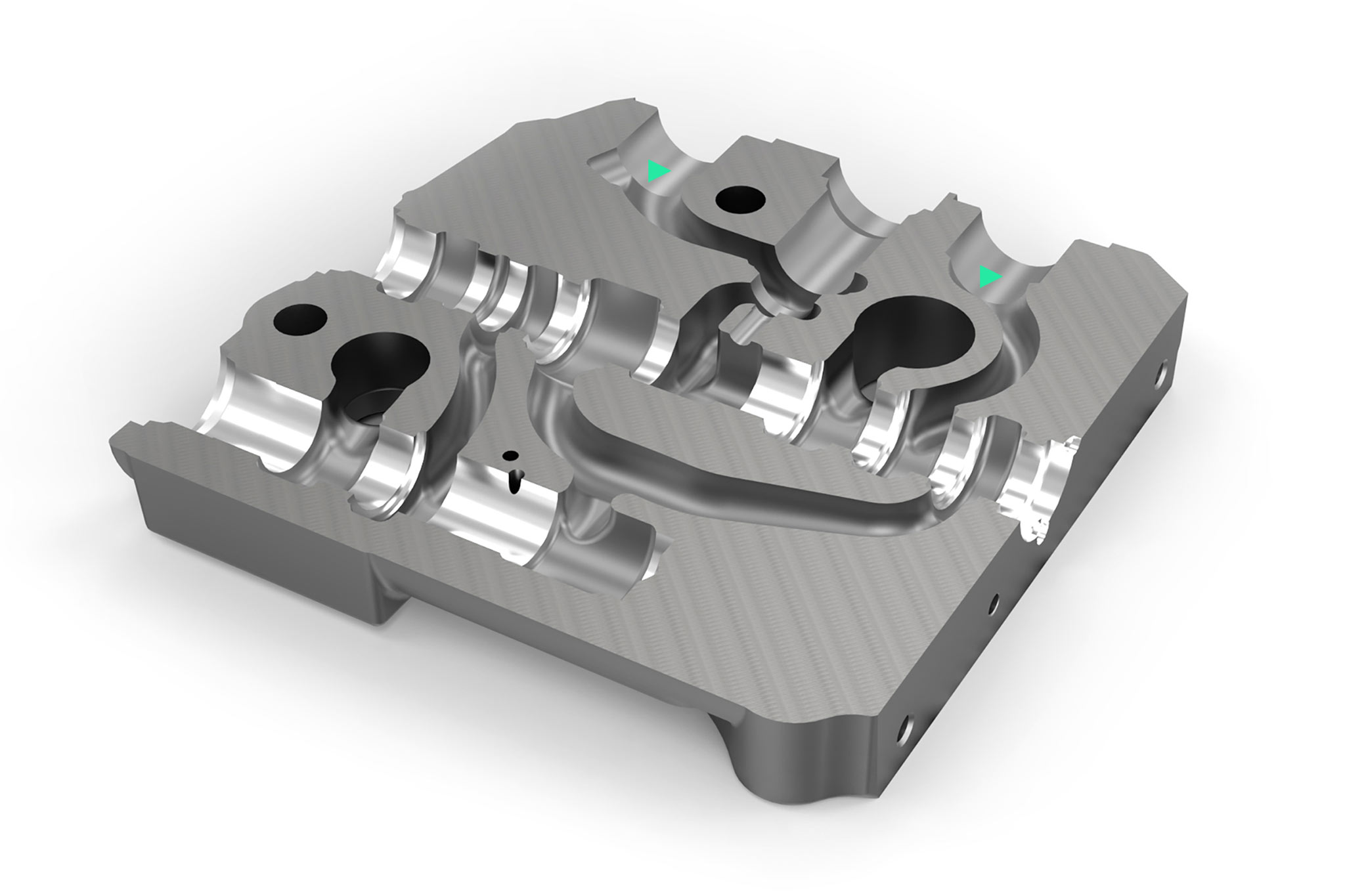

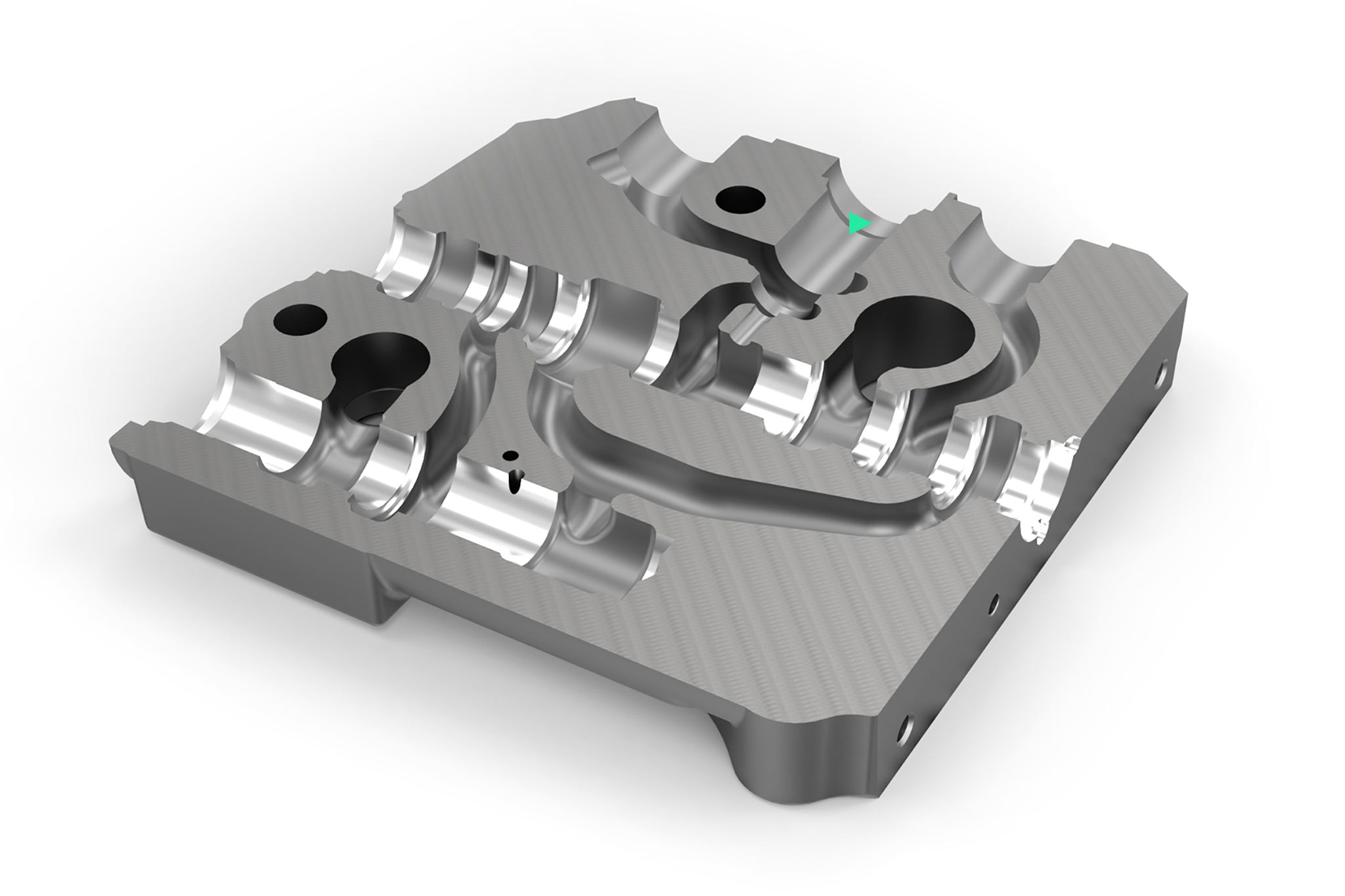

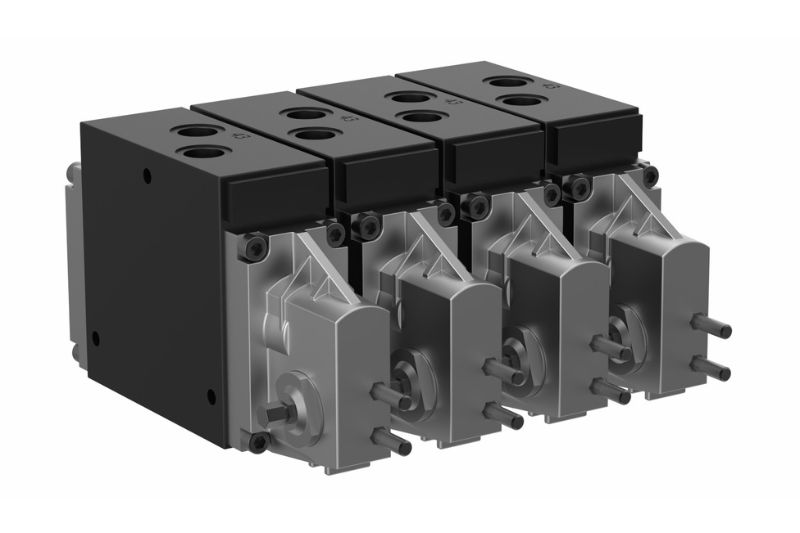

Carcasas de válvulas hidráulicas

Todo depende de la perforación principal. La fabricación de carcasas de válvula es la disciplina estrella del mundo de la tecnología de fluidos. Desde hace años, la experiencia de MAPAL en el sector de mecanizado de perforaciones de corredera ha sido muy demandada. De la exactitud de esta perforación depende la dimensión de la ranura con la corredera para que el aceite hidráulico solo pueda fluir en la dirección deseada sin que se produzcan fugas. Se trata de una definición muy estrecha para las válvulas hidráulicas modernas. Por este motivo, es necesario prestar especial atención a la circularidad, la forma cilíndrica, la rectitud y la calidad de la superficie de esta perforación.

Requisitos de mecanizado

- Situación cambiante de la medición de fundición

- Cortes severamente interrumpidos

- Evitar la formación de anillos durante el mandrinado y garantiza la retirada segura de las virutas de la carcasa

- Evitar las rupturas en los bordes de control en el proceso de taladrado

- Demandas muy altas de tolerancia de forma y posición

- Prestación constante antes del bruñido

- Considerar la variación de los componentes y los espacios limitados de almacenamiento de herramientas en el concepto de mecanizado

Válvula direccional

Las válvulas direccionales son válvulas de accionamiento mecánico o electrónico con varias posiciones de conmutación. Dependiendo de la posición especificada del deslizamiento de control a lo largo de los bordes de control, se establece un flujo de volumen para operar los implementos conectados. El compensador individual de presión (CIP) regula un gradiente de presión de carga constante sobre el borde de control de suministro del carrete de control, de modo que se logra un control del flujo del volumen independiente de la presión de carga en todo el rango de control, incluso en el funcionamiento paralelo (compensación de carga). El sistema debe estar libre de fugas para evitar el descenso involuntario de la carga, incluso durante el funcionamiento en paralelo.

Mecanizado de barrenos

Soluciones de aplicación

1 – Series pequeñas y medianas con herramientas fijas

Situación inicial del cliente

Carcasa de la válvula EN-GJS-400-15 – Perforación

- Pedidos individuales, pequeñas y medianas cantidades

- No es posible ajustar la herramienta

- Requiere poco tiempo de entrega

- Altas tarifas por hora de las máquinas

- Proceso estable de expansión y deshuesado disponible

- Concepto de herramienta adaptado a diversas variantes de componentes

2 – Producción a gran escala con herramientas fijas y ajustables

Situación inicial del cliente

Carcasa de la válvula EN-GJS-400-15 – Perforación de corredera y de equilibrio de presión

- Producción a gran escala

- Ajuste de la herramienta deseada

- Altas tarifas por hora de las máquinas

- Costos elevados para el bruñido posterior de las espinas

3 – Tamaños de lotes reducidos: reducción en los cambios de herramientas gracias a las herramientas combinadas

Situación inicial del cliente

Carcasa de la válvula EN-GJL-300 – Perforación

- Lotes pequeños

- Posibilidad de ajuste de la herramienta disponible

- Demasiados/frecuentes cambios de herramientas

- Altas tarifas por hora de las máquinas

- Alto esfuerzo debido al bruñido de espinas

4 – Bruñido flexible en el centro de mecanizado

Situación inicial del cliente

Carcasa de la válvula EN-GJS-400-15 – Perforación/bruñido de equilibrio de presión

- Exigencia de reducir los costos auxiliares

- Centro de mecanizado existente convertido en TOOLTRONIC

- Bruñido para la construcción de prototipos, así como para series pequeñas y medianas

- Necesidad de guardar el proceso de bruñido en una máquina separada

5 – Gestión de herramientas

Situación inicial del cliente

Carcasa de la válvula EN-GJS-400-15 – Mecanizado completo

- Niveles de existencias elevados

- Los flujos de procesos en la sala de configuración no son óptimos y la calidad de los datos es incompleta

- Transparencia insuficiente de los costos

- Alta fluctuación debido a la escasez general de trabajadores cualificados

- Problemas de ruptura de herramientas

- Costos elevados de las herramientas

Soluciones de mecanizado

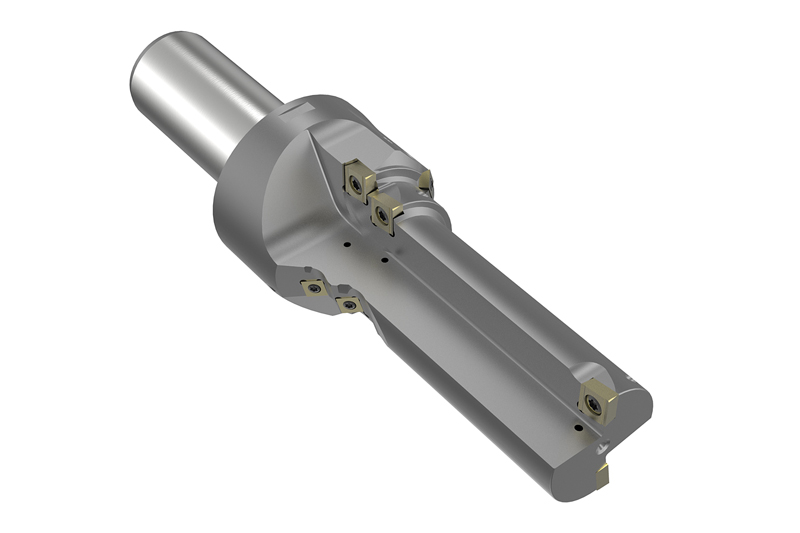

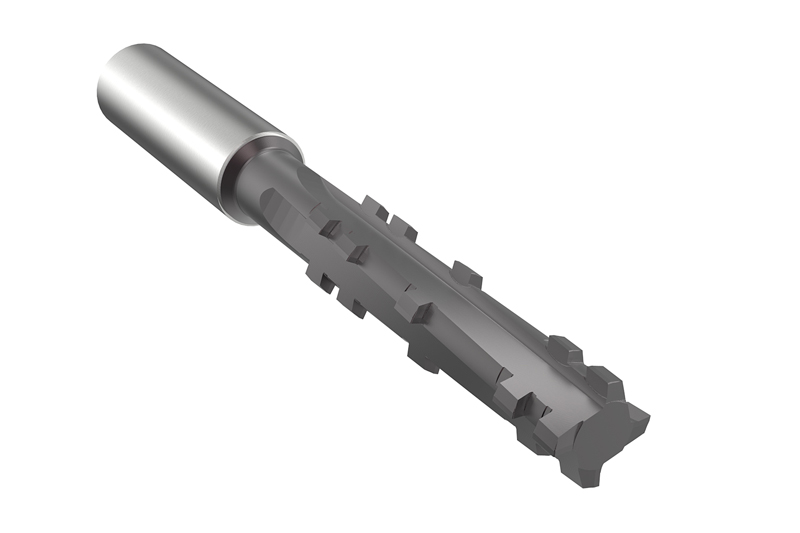

Pilotaje y taladrado

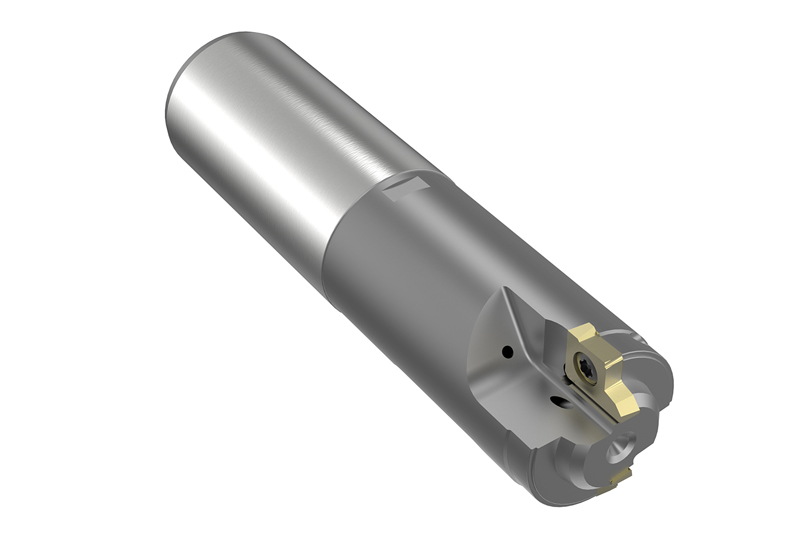

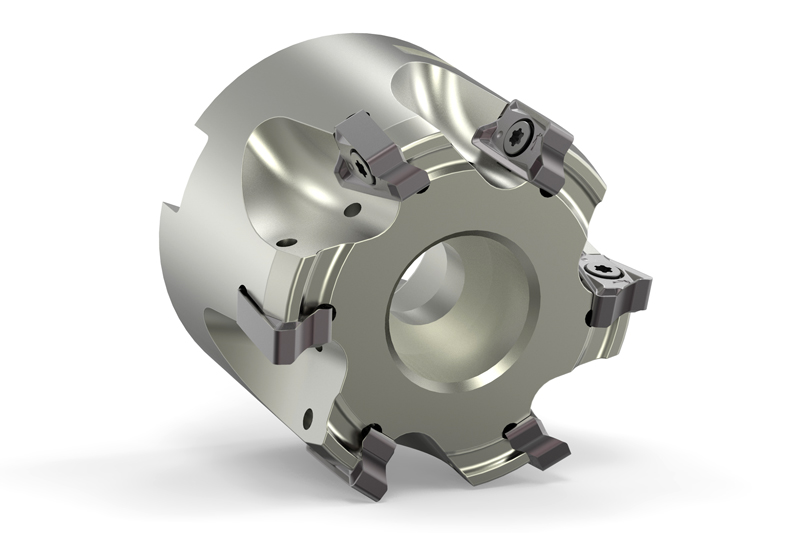

Mecanizado de bordes de control

Escariado y taladrado de precisión

Mecanizado de acabado por bruñido

Fresado

Sujeción