04.10.2021

Continuous process for electromobility

Internal and External Machining of the Stator Housing

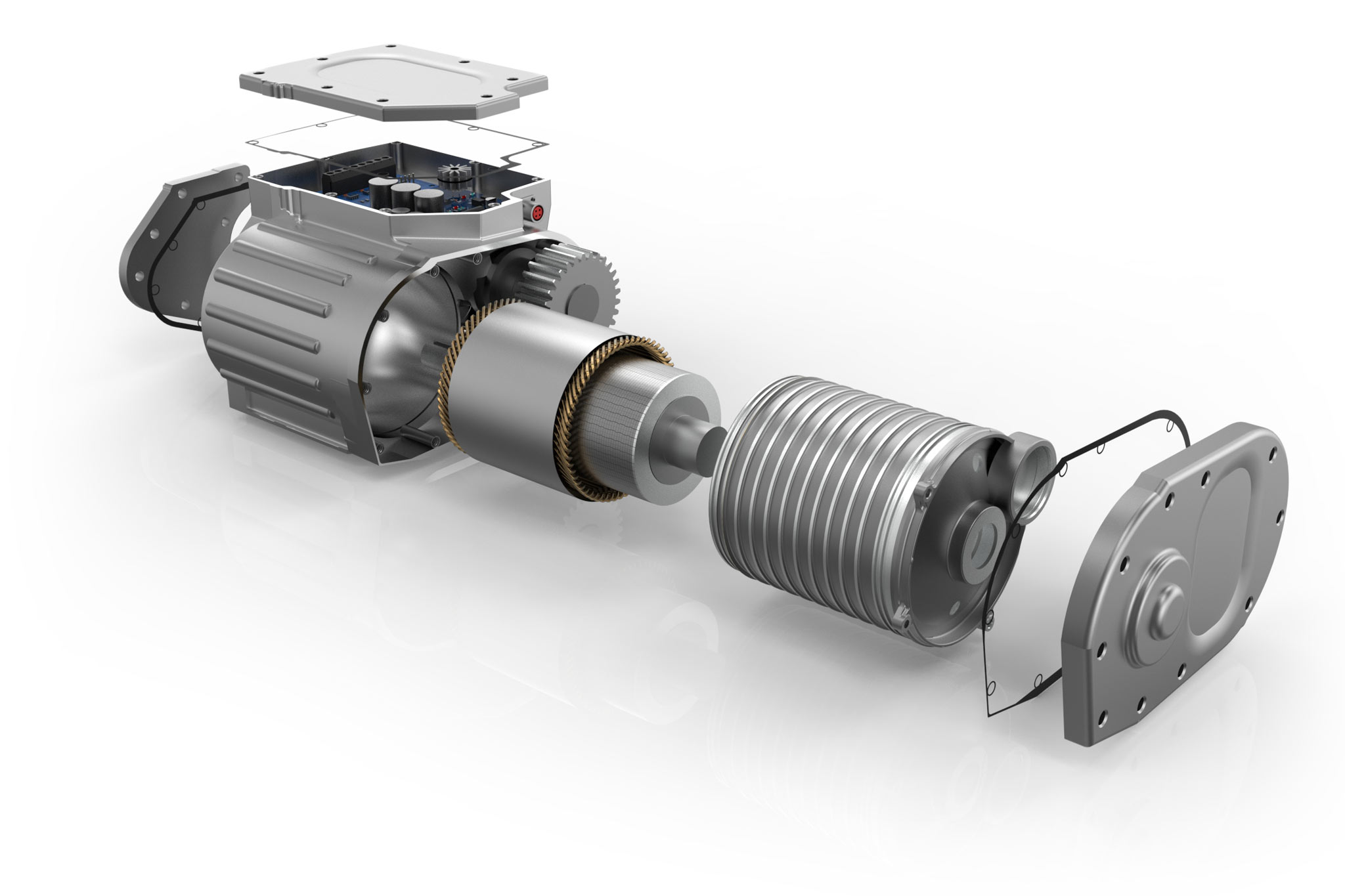

With increasing numbers of electric vehicles, not only very precisely manufactured parts are required, but also the most efficient production possible. One part that is particularly demanding in terms of machining is the motor housing for the electric motor. MAPAL has already established a three-stage solution for machining the stator bore. The precision tool manufacturer now presents a large tool for external machining.

Three-stage solution for the stator bore

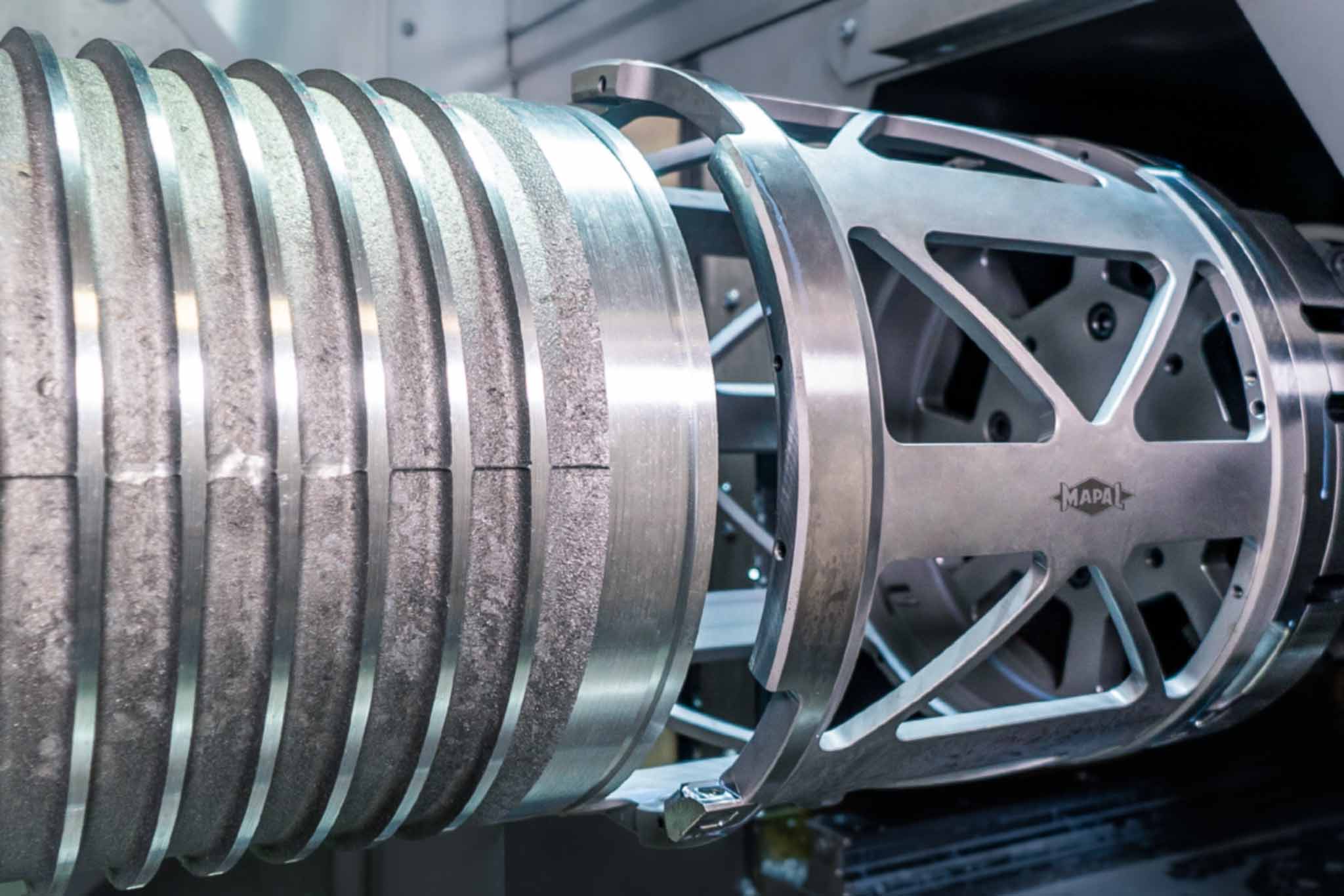

World first for external machining

On the outside, the part features a helical circumferential groove. Because the coolant later flows through this groove after it’s been inserted into the outer housing, the stator carrier is also known as the "cooling jacket".

MAPAL is presenting new external machining tools at the EMO in Milan. They are among the more unusual tools. After pre-machining, a bell-shaped tool takes over the complete finishing of the outside. The specifically designed lightweight tool is equipped with indexable inserts and guide pads and was provided with bars in the right places to save as much weight as possible and to get rid of chips through large openings. The fine machining tool promises high roundness and accuracy.

Complete machining on machining centre

Internal machining is possible very quickly and accurately with the boring tools. In addition, the outside can also be machined in the same clamping setup without moving. The machining centre solution caters to customers who are embracing the transformation to e-mobility with existing machinery geared to machining large cubic aluminium housings.

Those who start their production on a greenfield site can, of course, choose which machining strategy is best for them. MAPAL has developed an alternative machining solution in a joint project with a machine manufacturer. In this case, the process was rotated 90 degrees for use on vertical lathes.

Contact

Kathrin Rehor Public Relations Kathrin.Rehor@mapal.com Phone: +49 7361 585 3342