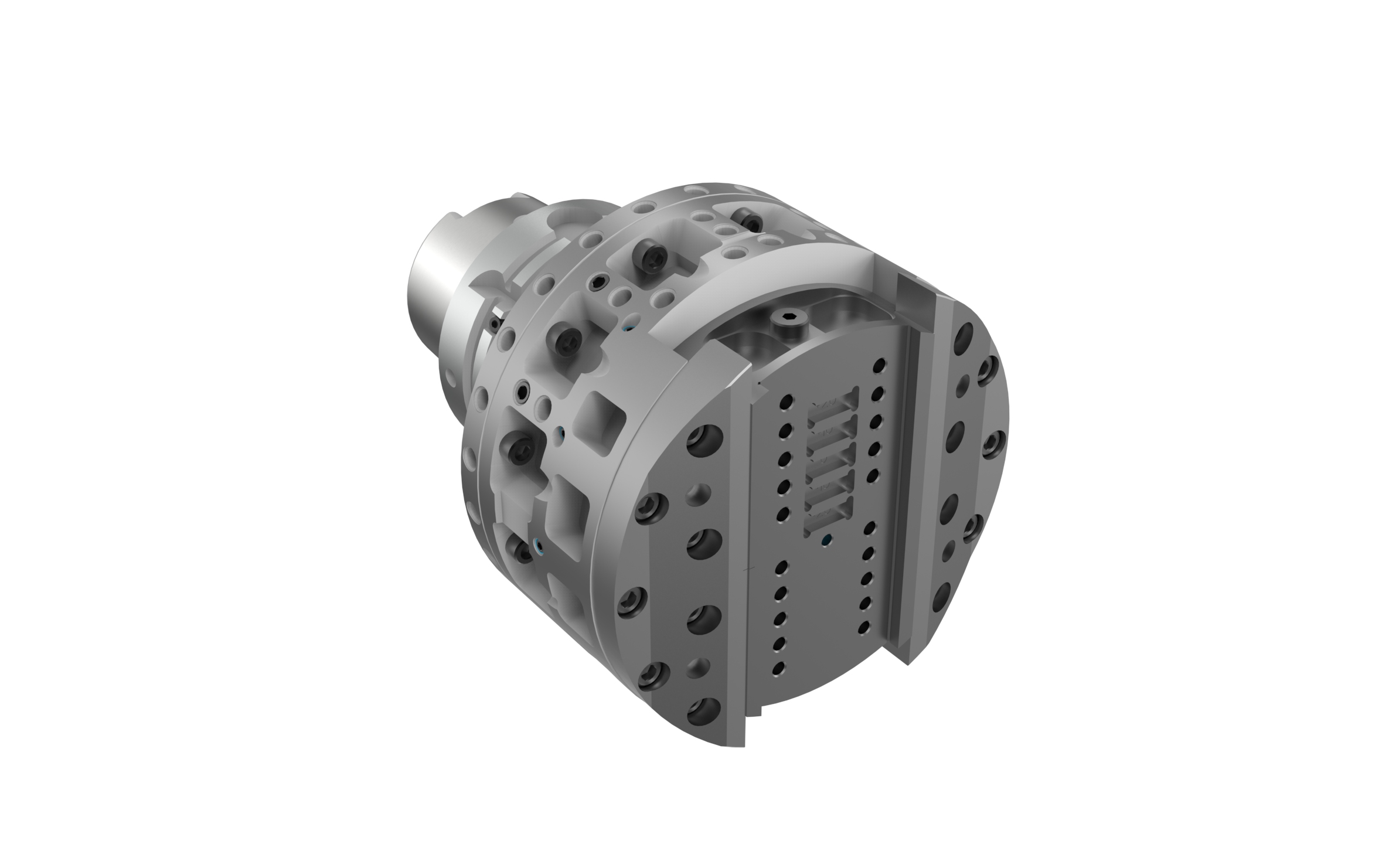

Actuator housing

制御技術による加工ソリューション

アクチュエーターハウジング(AlSi10)

お客様の初期の加工状況

- 単一の工具システムでの複雑な輪郭加工の要求に対応:端面加工、面取り、内径加工、1:50(1.1146°)のテーパ加工

- 高い形状 & 位置精度およびIT8公差への高い要求

ソリューションの特徴

- 内外径加工の最適な同軸度を確保しつつ安定したプロセスを実現

- 自動工具交換が可能

- 姉妹工具を使用することで、加工時間の短縮が可能

- セッティングフィクスチャーでの事前調整が可能な柔軟なプロセス

- 標準工具(ドリルやミーリングカッターなど)を同じスピンドルで使用可能

- インサートテクノロジーによる工具材料費の低減

ツールハイライト

- HSK-A100 + U軸(回転軸)を用いた加工

- 内外径加工を1つのセットアップツールで実現

- 表メインストローク56mm

- 加工直径範囲112mm

- 最大加工径を確保するため、セットアップツールを5段階で調整可能

- 刃先への最適なクーラント供給を可能にする内部給油方式

.pptx - PowerPoint/2023-11-29-14-00-36-Aussteuern-Kundenpr-sentation-EN-1-.pptx-PowerPoint.jpg)

利点

- 単一の工具システムで複雑な形状と要求精度を実現

- すべてのバリエーションに対し、2種類のツールのみで対応可能なため、量産時の工具材料費を削減

- 1:50(1.146°)の自由形状およびテーパ形状をプログラム・修正可能なため、高いプロセス安定性を確保

- マパールとの技術提携により、すべての加工工程を統合可能