Flexible honing on the machining centre

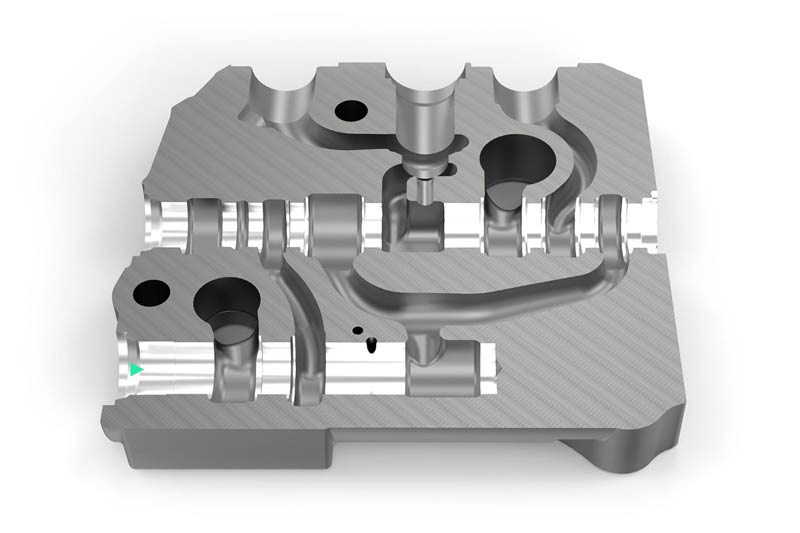

Valve housing EN-GJS-400-15 – Compensator bore / honing

Initial situation at the customer

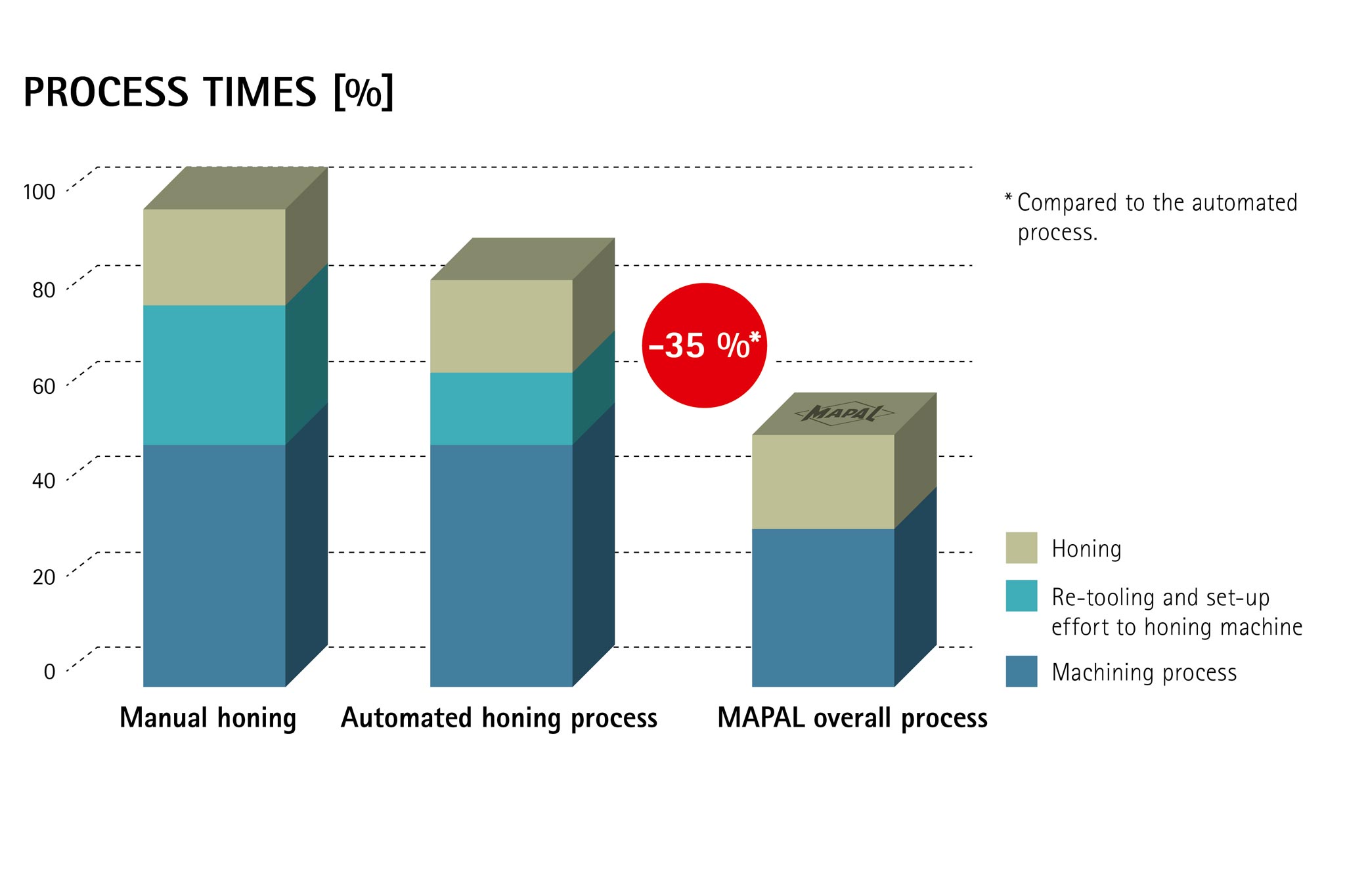

- Request for reduction of ancillary costs

- Existing machining centre re-tooled to TOOLTRONIC

- Honing for prototype manufacture, as well as small and medium-scale production runs

- Requirement for saving the honing process on separate machine

Special features of this solution

- A full NC axis incorporated in the machine control system

- Shortening of production and lead times

- Improved surface quality

- Greater contour accuracy

Compensator bore

Fine machining with honing

- Significant shortening of production and cycle times

- Greater contour accuracy

Honing with TOOLTRONIC

Machining with MAPAL TOOLTRONIC achieves high surface quality and dimensional accuracy with tightest manufacturing tolerances as well as high flexibility in manufacturing. The wear of the honing bars is reliably compensated by a highly sensitive and precise actuating movement (EAT system).

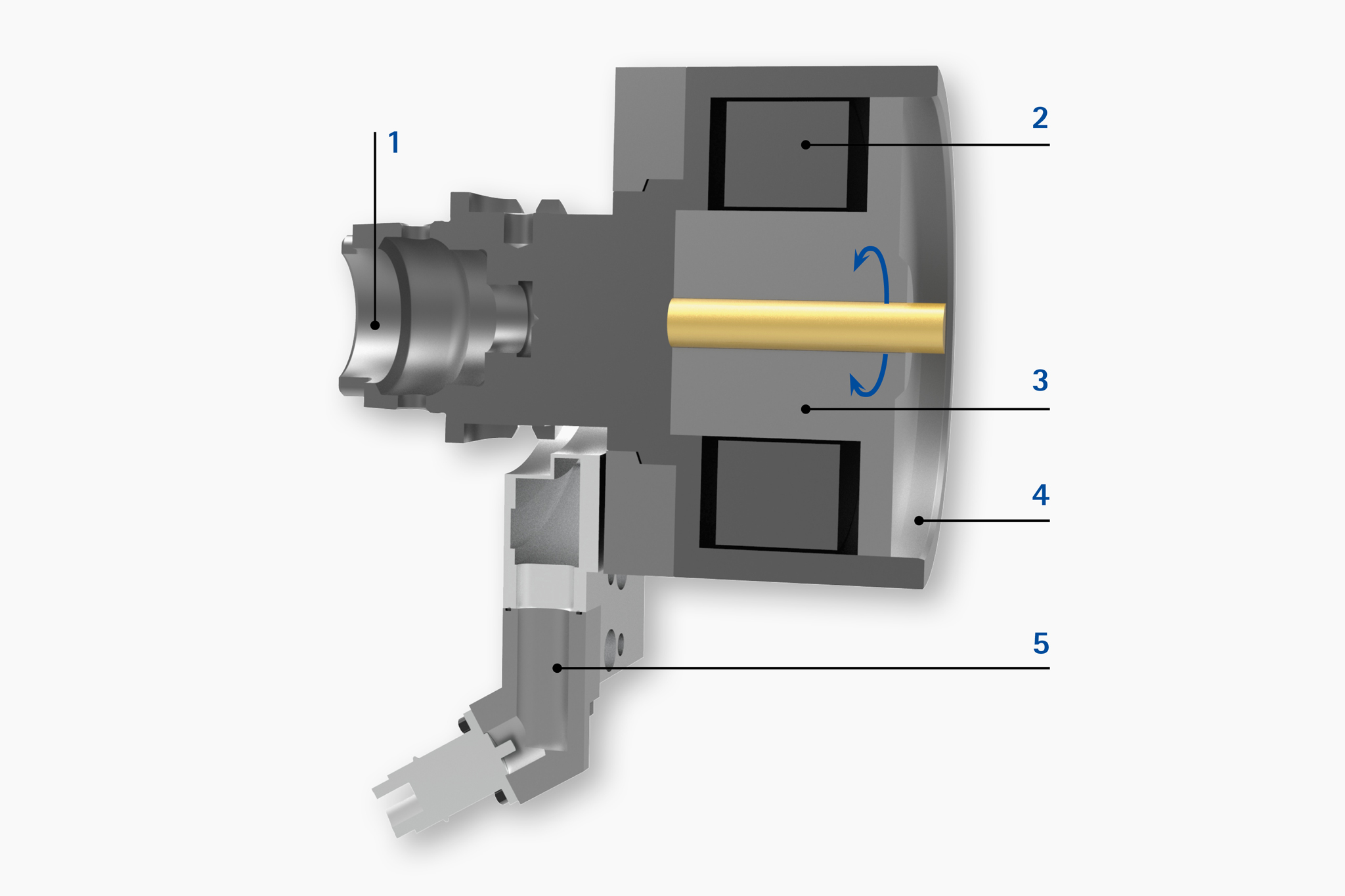

MAPAL TOOLTRONIC: design and advantages

TOOLTRONIC design for machining centres:

- Machine connection

- Electronics

- Motor unit with defined connection point

- Modular connection

- Stator (stationary unit)

ADVANTAGES OF THIS HONING:

- Very tight manufacturing tolerances as well as flexibility in manufacture

- High surface quality and dimensional accuracy

- Major saving and quality potential for prototypes, small-scale and medium-scale series production

- Time-consuming re-tooling is not necessary

Advantages

- Tolerances to be achieved: Accuracy of diameter IT 6 and roundness < 5 μm

- Turning with a stationary, firmly clamped part

- Burr-free, rounded transitions possible

- Reduced/low number of custom tools

- Low-maintenance system with eccentric actuating tool (EAT system)

- Almost all machining centres can be re-tooled to MAPAL TOOLTRONIC technology

- Reclamping error due to re-tooling to honing machine no longer applies

- Complete process of compensator bore can be mapped by MAPAL (highest economic efficiency & process reliability)