NeoMill®-Fräser vereinen Produktivität und Wirtschaftlichkeit

Lavorare nel mondo IT

Stabiliremo insieme la rotta per il tuo futuro, affidandoci all’umanità e alla lungimiranza di un'organizzazione ben studiata. Questo rappresenta la base per una prospettiva previdente e affidabile, nonché per la qualità dei nostri prodotti e sevizi. E noi, in qualità di datore di lavoro e partner tecnologico, ne andiamo molto fieri. Ora vogliamo continuare a crescere, con te nel nostro team.

Non sei solo un appassionato sostenitore della digitalizzazione, ma contribuisci anche a crearla scrivendo da zero ogni riga di codice? Questo ti rende perfetto per il nostro team: perché abbiamo posto la digitalizzazione al centro delle nostre competenze e dei nostri servizi. Lavoriamo a livello internazionale, in team agili e con strumenti e strutture all’avanguardia. Ciò si traduce in progetti e opportunità di carriera stimolanti – per te insieme a noi.

AT A GLANCE

-

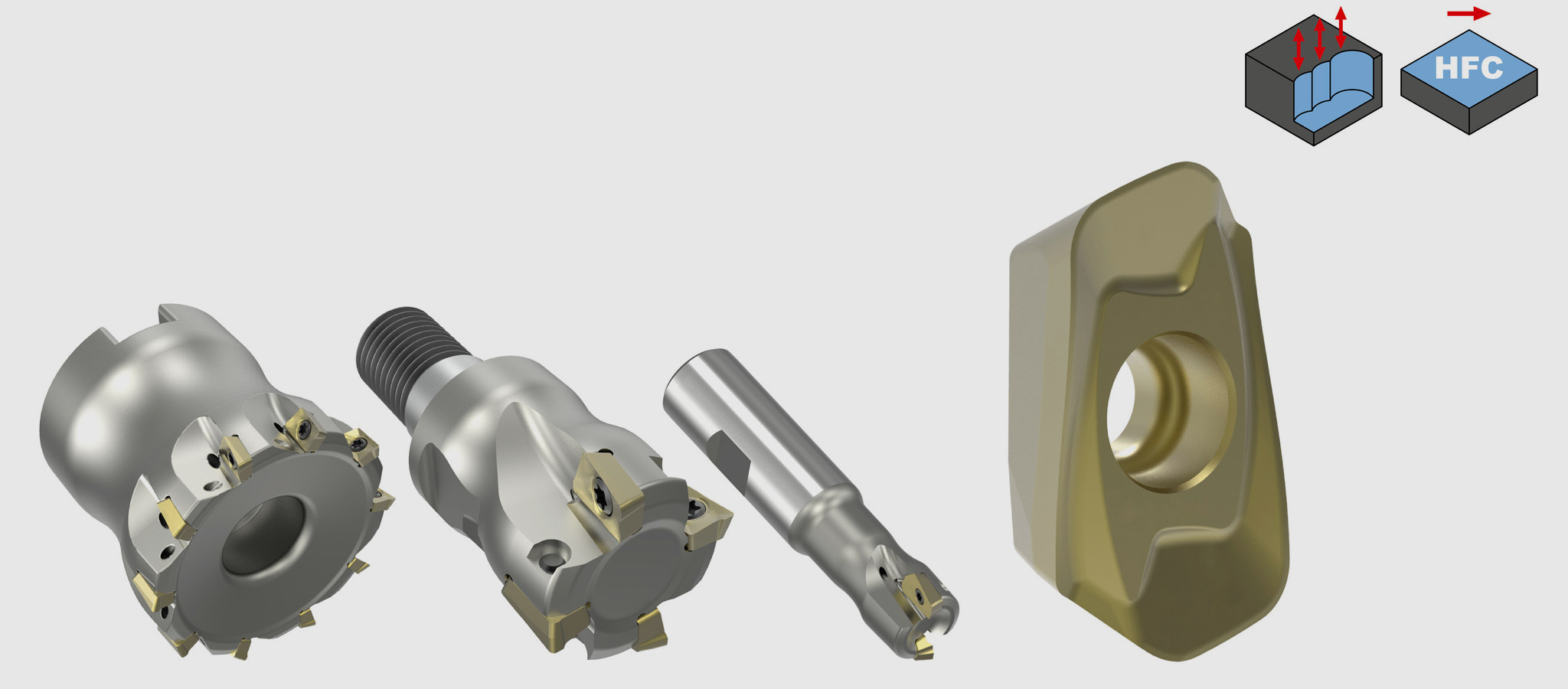

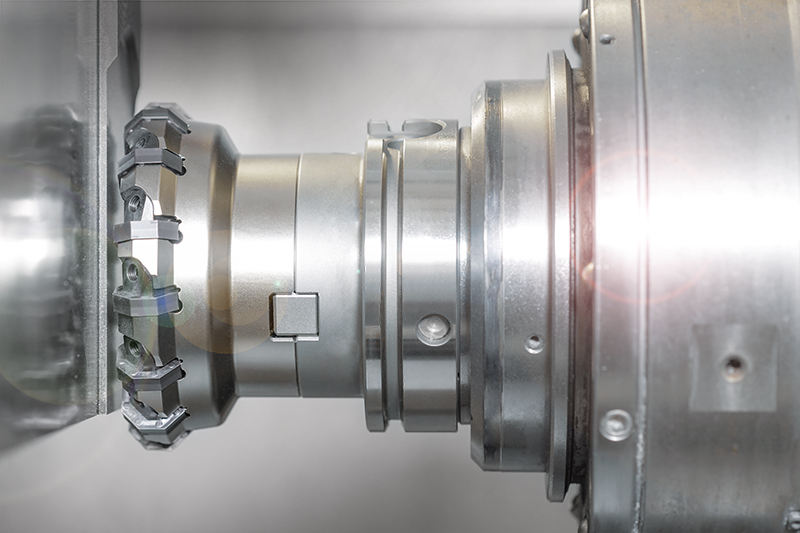

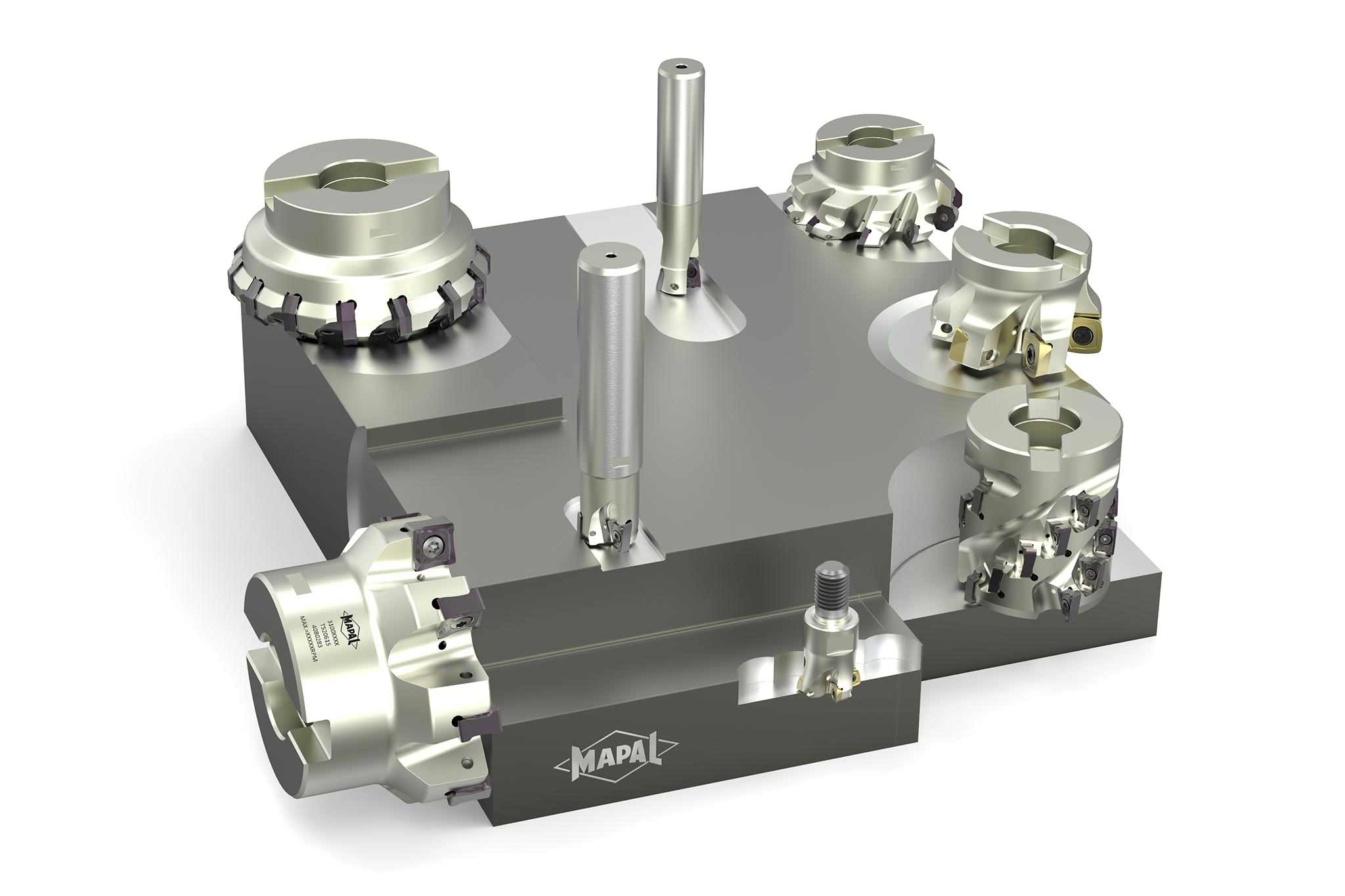

Milling cutter range with compacted radial indexable inserts

- Face, shoulder, slot and shell end face milling cutters

- For roughing and medium machining with one tool

- Positive and negative indexable inserts made from different PVD and CVD cutting materials

ADVANTAGES

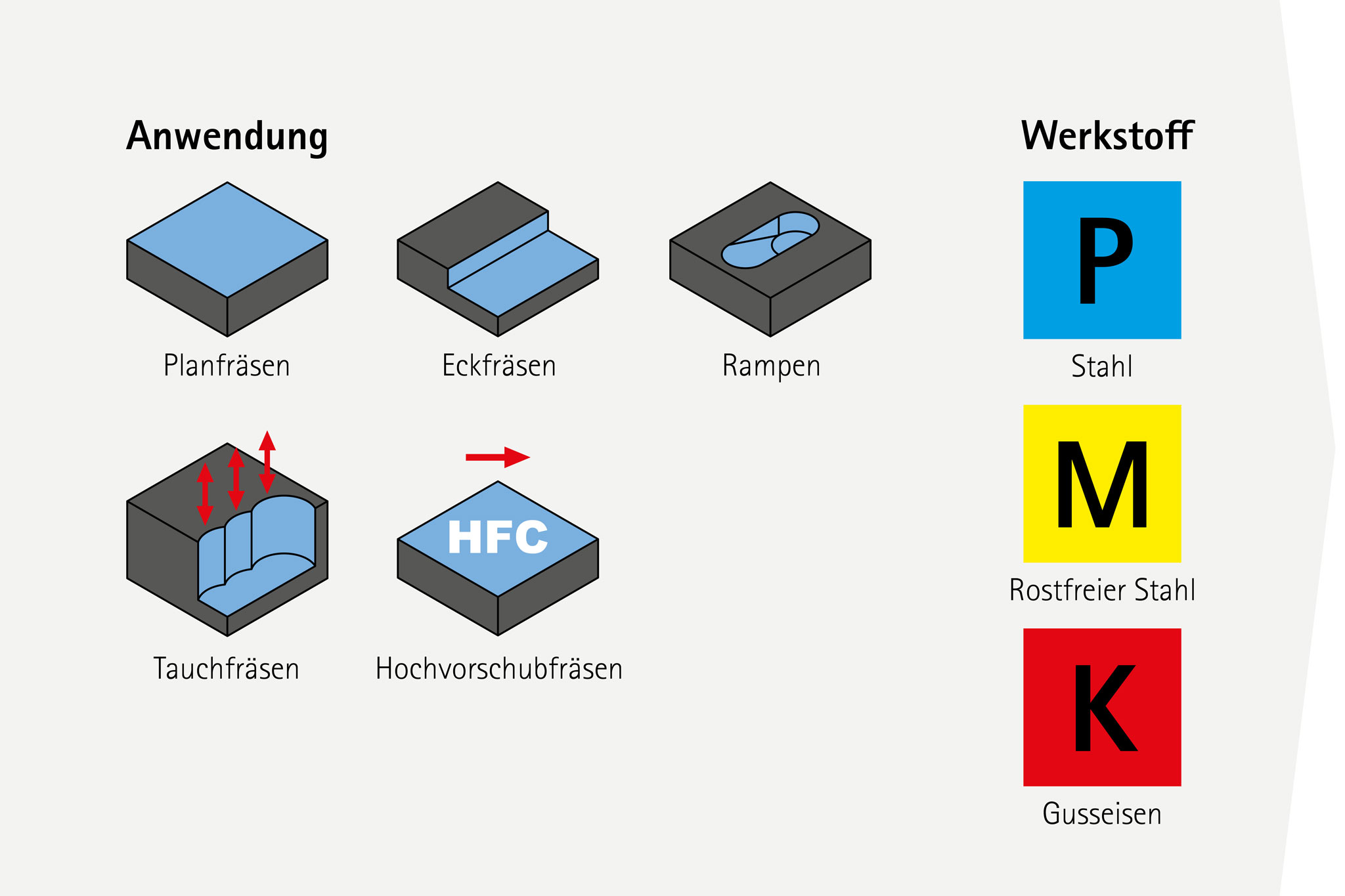

- Indexable inserts for maximum efficiency also in difficult machining conditions

- Very high surface quality due to indexable inserts with wiper component

- For all applications in cast iron, steel and stainless steel, as well as heat-resistant cast steel (turbocharger materials)

- High cutting volume

NeoMill® standard programme

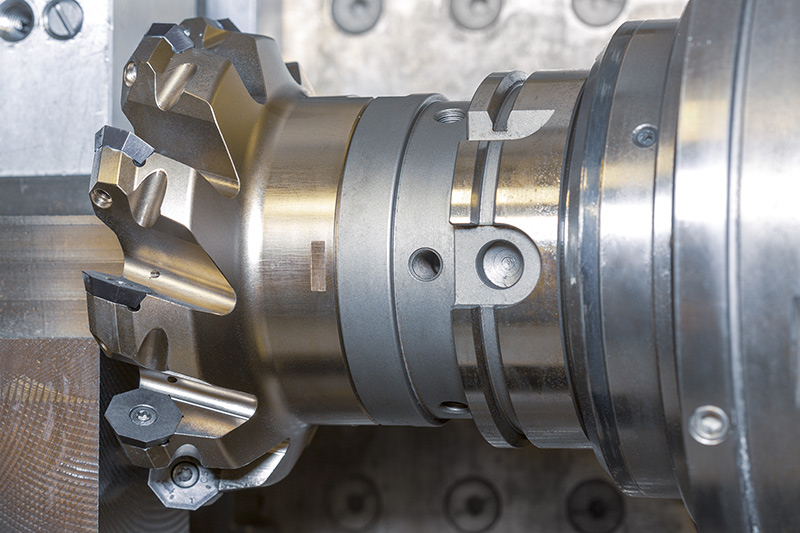

For all milling cutters, MAPAL offers a wide range of indexable inserts – each in a positive and a negative design. In addition, there are cutting edges with a wiper portion, which achieve good surface qualities even without being set.

The negative inserts do not have a clearance angle and can therefore be designed with cutting edges on the contact surface. If the basic shape is the same, negative inserts thus have double the number of cutting edges compared with their positive counterparts. In combination with the high tool life of the indexable inserts, this makes the negative indexable inserts particularly cost-effective.

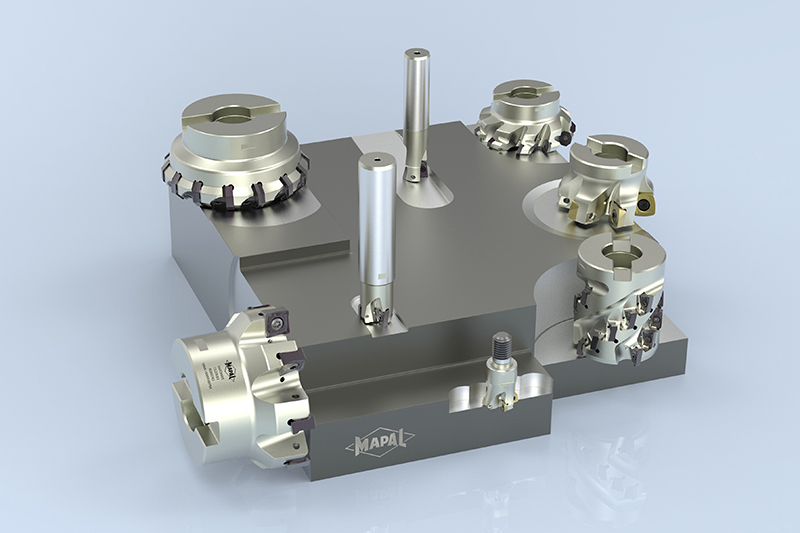

Anwendungsbeispiele

Downloadbereich:

Auswahlschritte zum NeoMill®-Fräser

Innovative und prozesssichere Zerspanungslösungen erfordern ein ganzheitliches Prozessverständnis

-

Fräsanwendung & Aufspannung

Bauteilanforderungen und Spannkonzept -

Bearbeitungs-

strategieWerkzeugauswahl und Auslegung der Frässtrategie -

Steigerung der Produktivität

Analyse und Optimierung der Schnittparameter und Taktzeit -

Standard-

programmAb Lager verfügbare Werkzeuge und Wendeschneidplatten

-

Prozess-

sicherheit & Wirtschaft-

lichkeitUnterstützung beim Einsatz im Prozess

-

Partnerschaftliche Zusammenarbeit

Enger Kontakt und Optimierungspotentiale verbessern

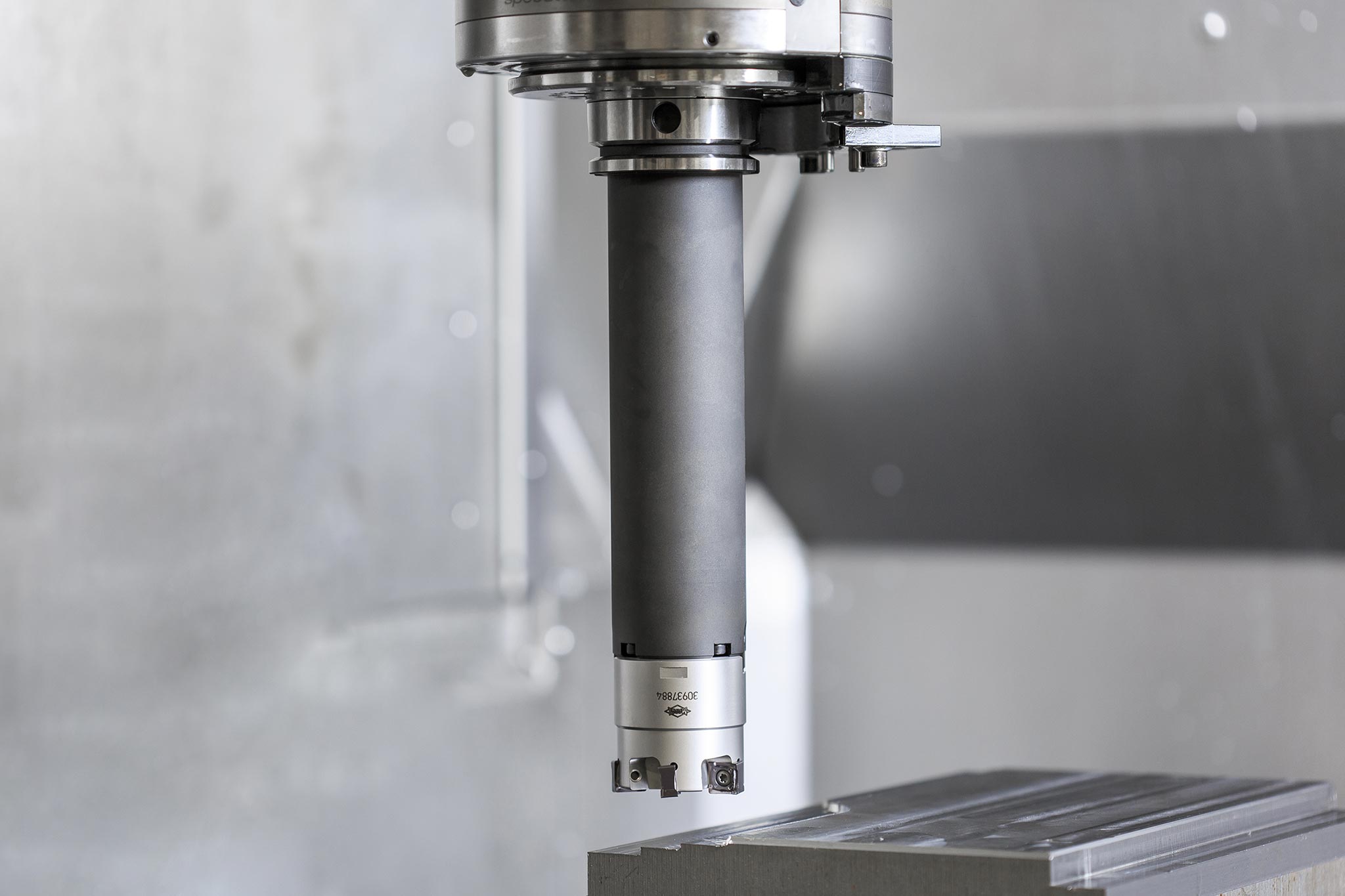

Vibrationen vermeiden durch Schwingungsdämpfungssysteme

Die perfekte Lösung für Ihre Fräsanwendung

Ihr direkter Kontakt

Ansprechpartner

Heiko Rup Product and Application Management heiko.rup@mapal.com Phone: +49 7361 585 3034