TOOLTRONIC e cabeçotes e facear

TOOLTRONIC – o acionamento universal para maior variedade de opções de fabricação e flexibilidade em centros de usinagem e máquinas especiais. O TOOLTRONIC para centros de usinagem é um eixo de ferramenta adicional intercambiável completo que possibilita um amplo leque de aplicações.

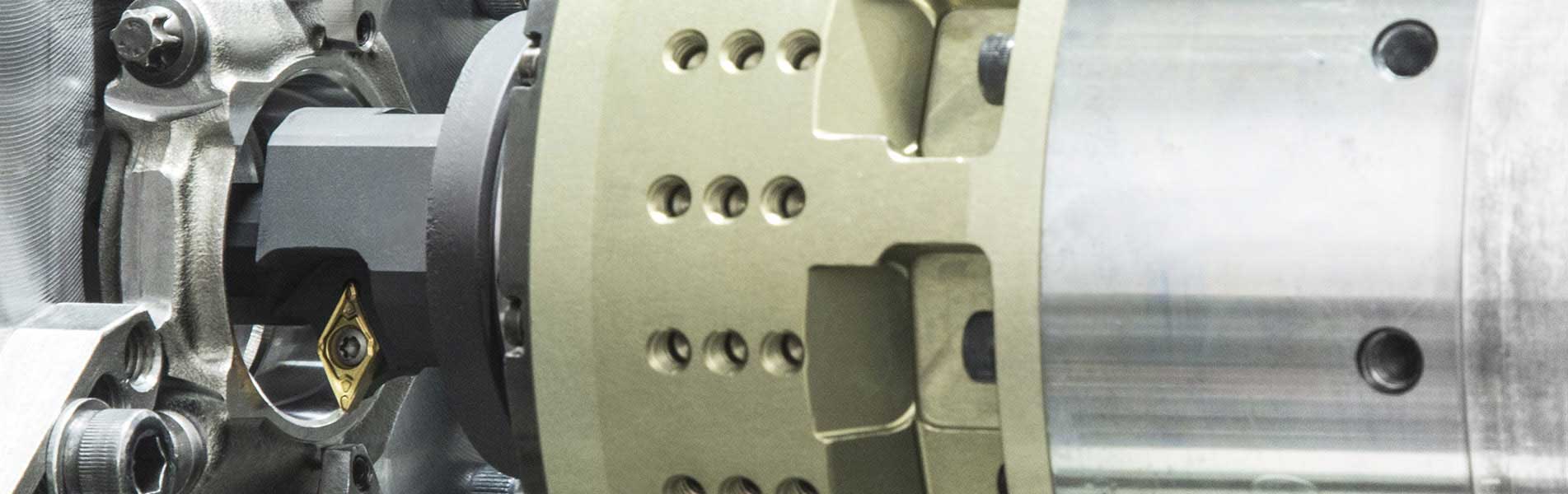

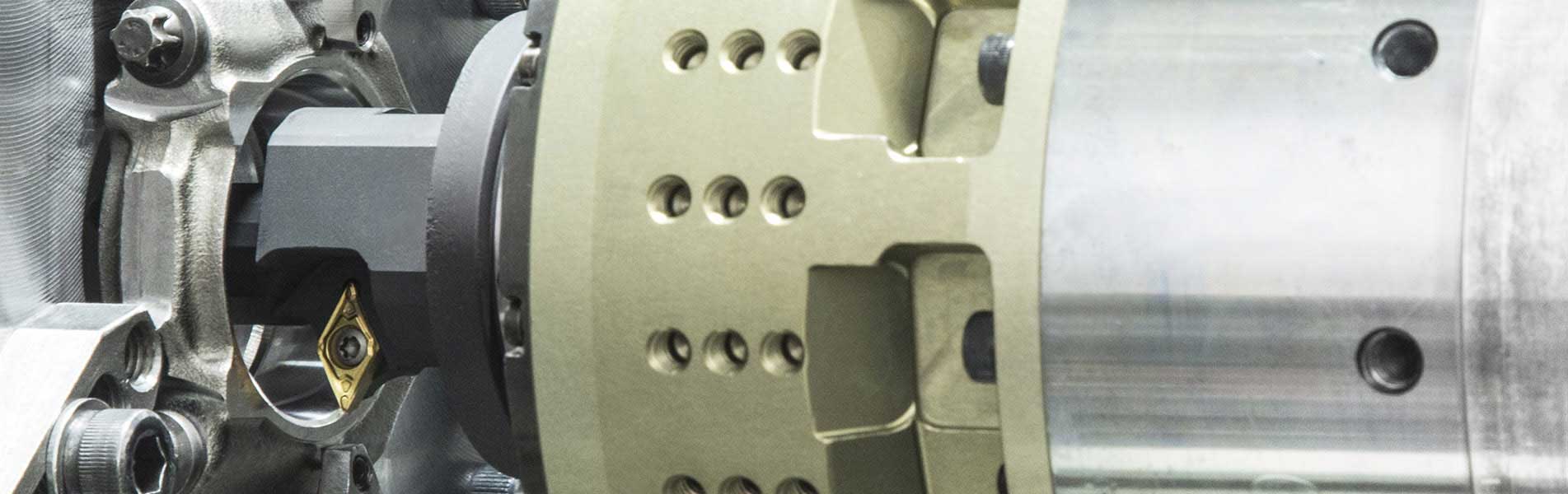

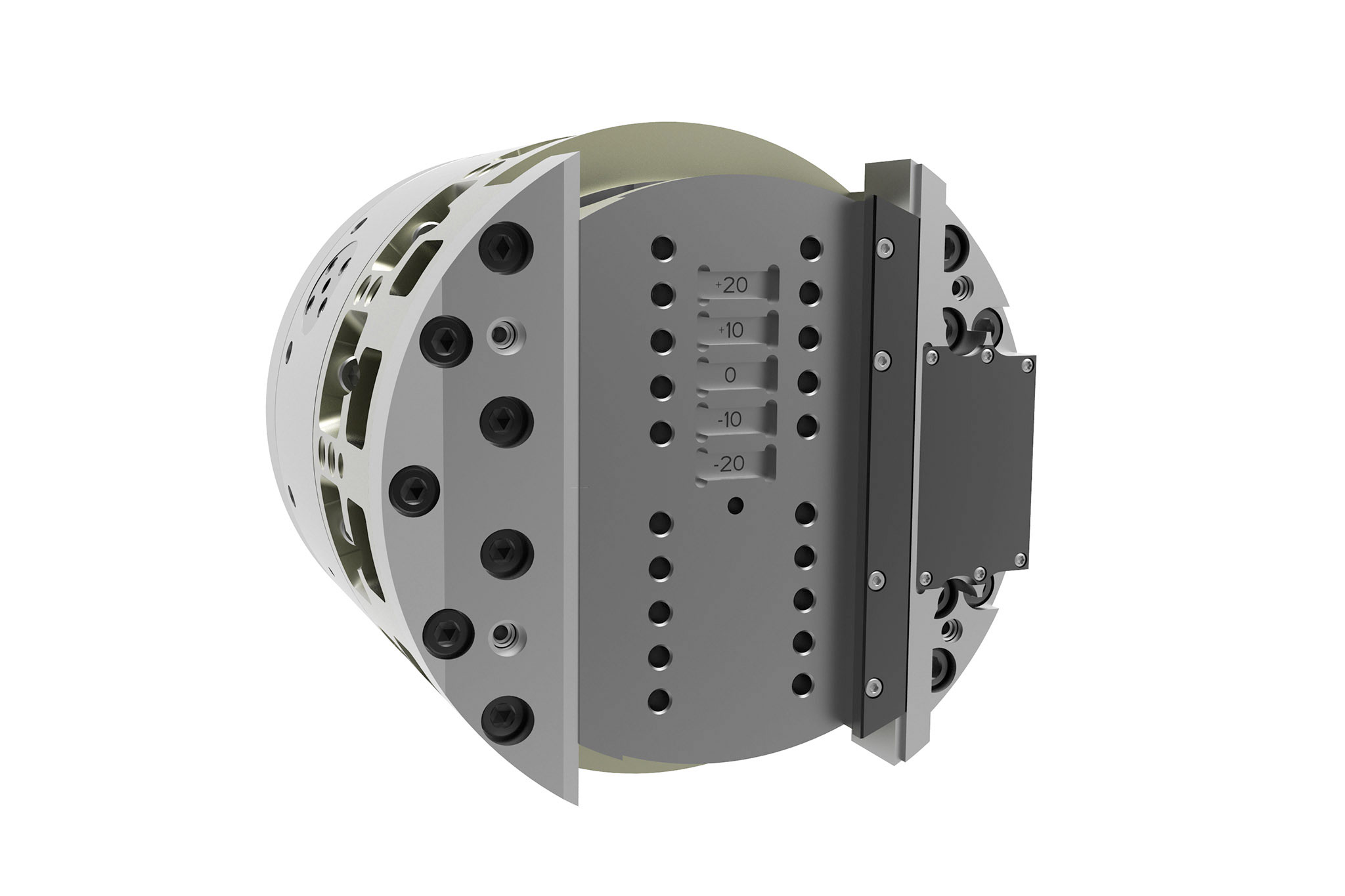

Cabeçotes de facear são utilizados para faceamento, usinagem de canais e de contornos, principalmente na fabricação de grandes séries em máquinas especiais. O acionamento destas ferramentas de corrediça e a atuação dos porta-ferramentas e arestas de corte é realizado por um dispositivo de avanço transversal comandado por NC, localizado no acionamento do fuso ou no lado traseiro da unidade de avanço.

Cabeçotes de facear são utilizados para faceamento, usinagem de canais e de contornos, principalmente na fabricação de grandes séries em máquinas especiais. O acionamento destas ferramentas de corrediça e a atuação dos porta-ferramentas e arestas de corte é realizado por um dispositivo de avanço transversal comandado por NC, localizado no acionamento do fuso ou no lado traseiro da unidade de avanço.

O sistema de ferramentas mecatrónicas TOOLTRONIC

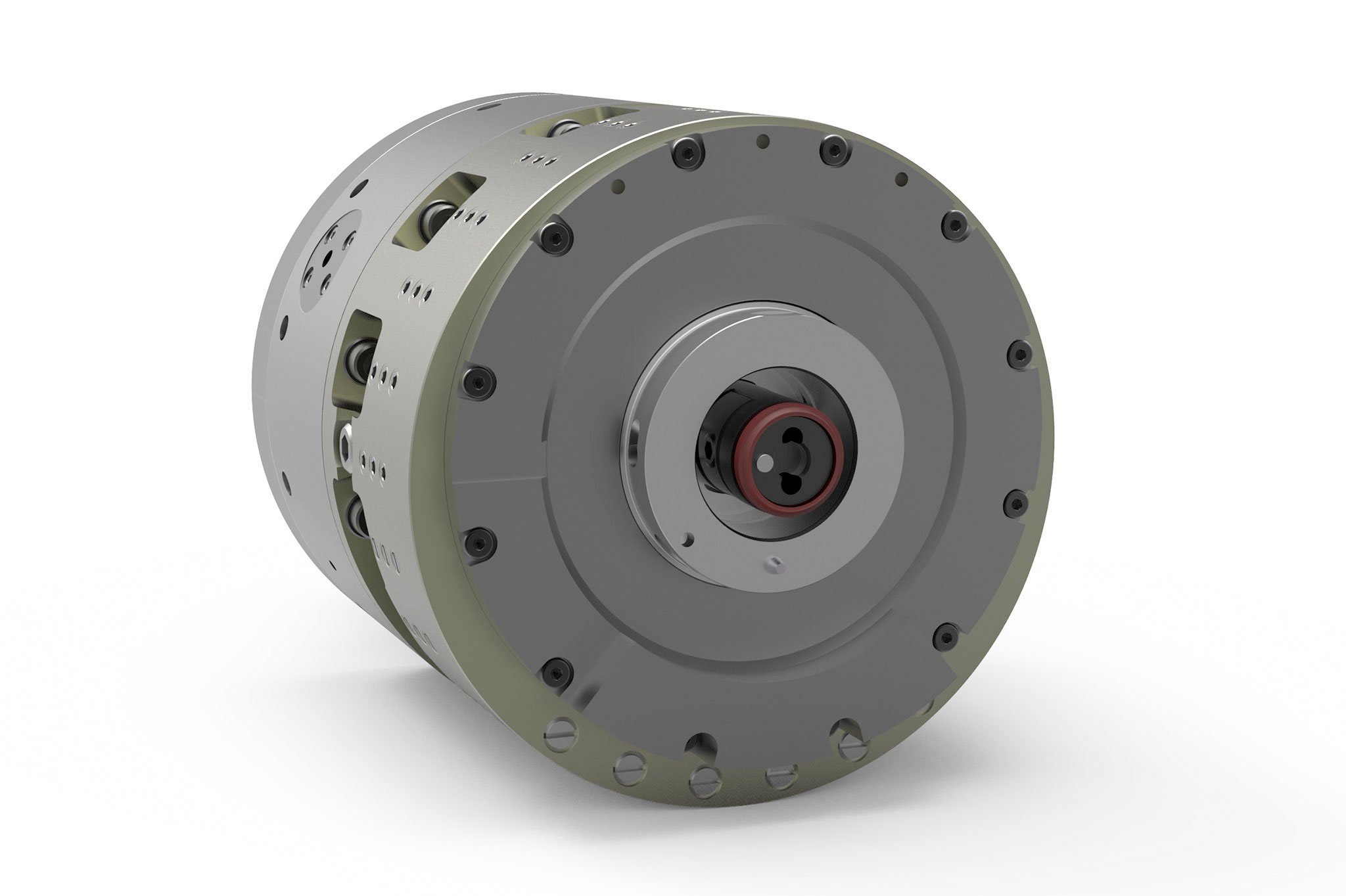

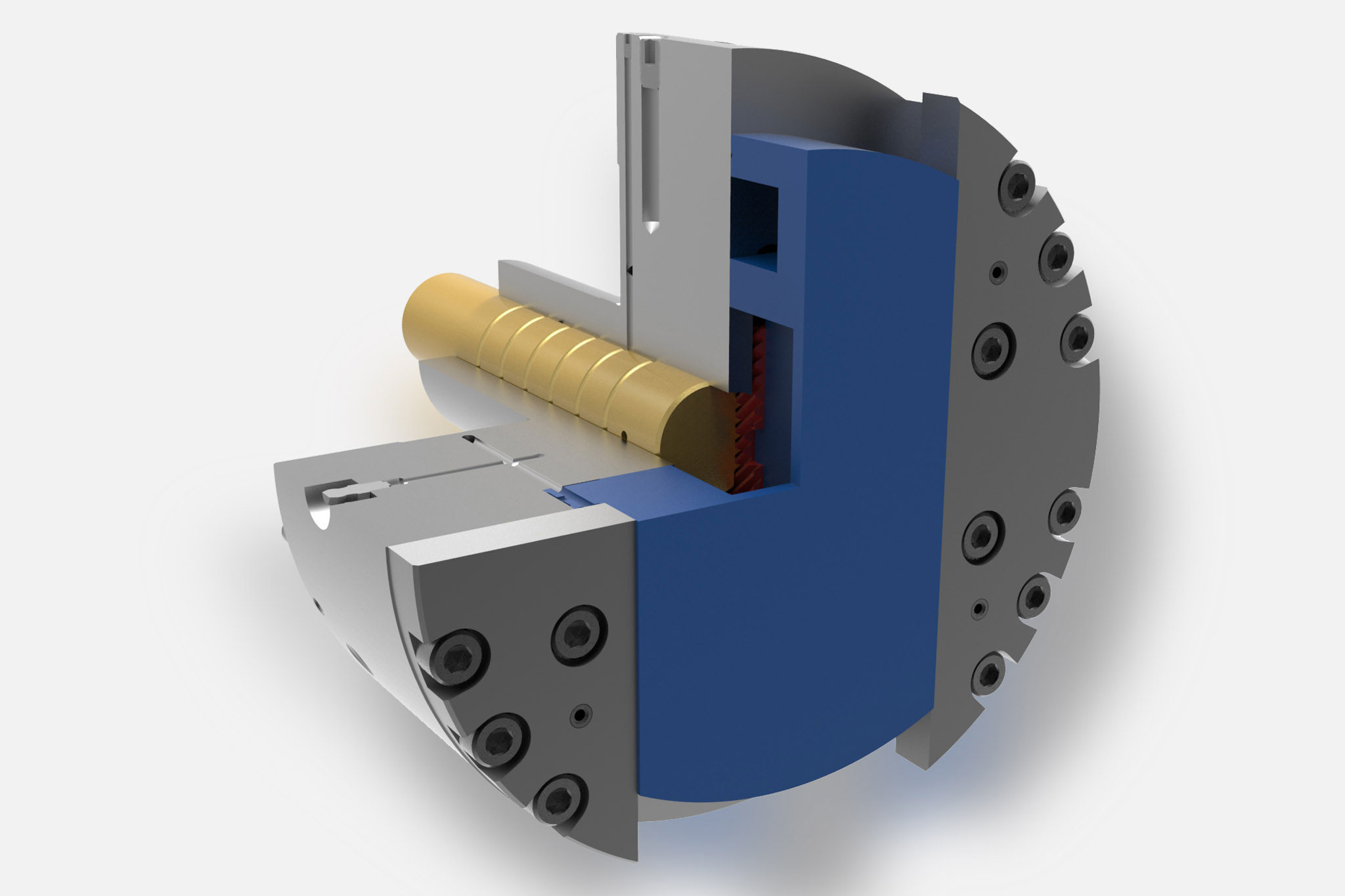

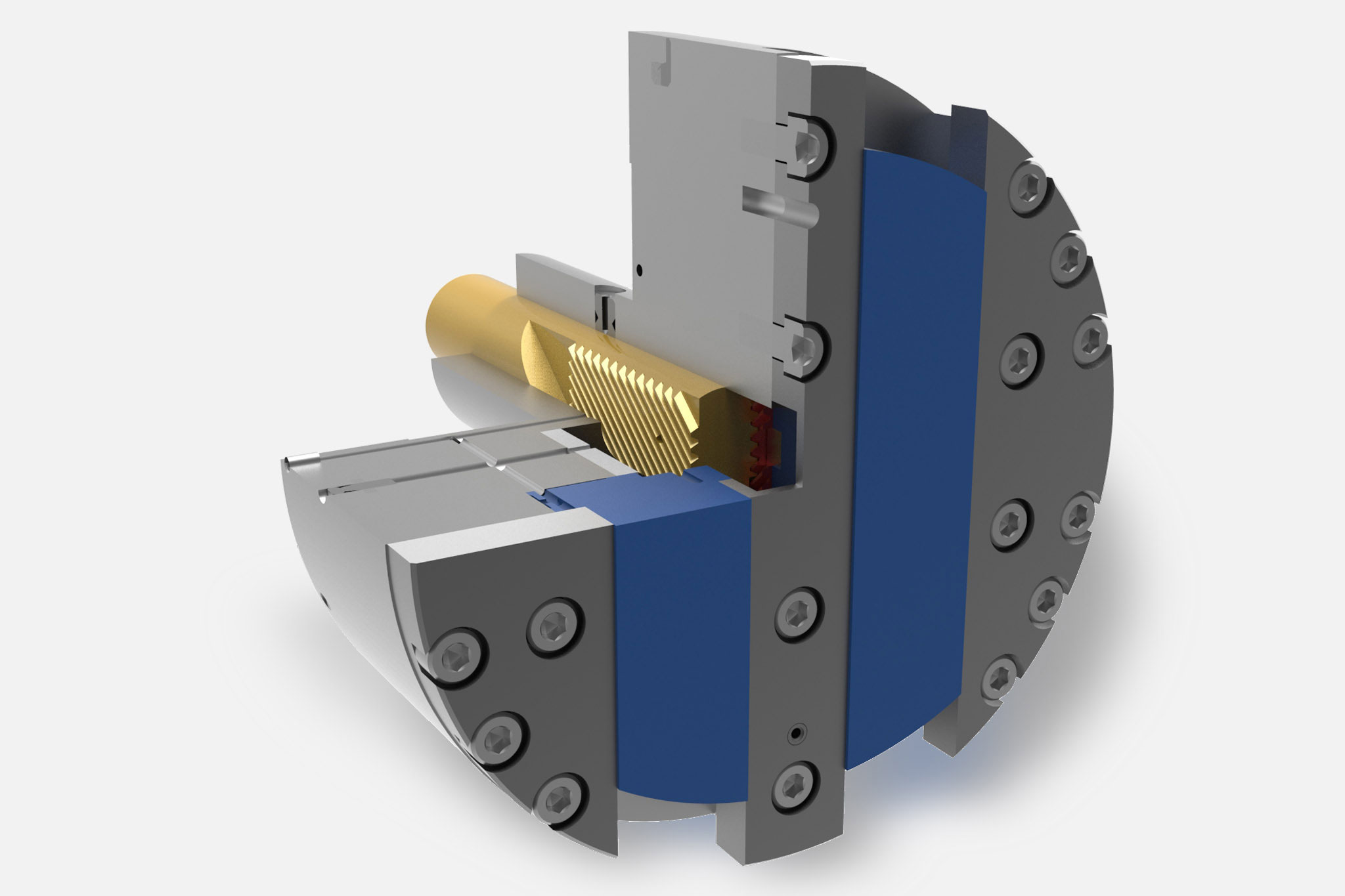

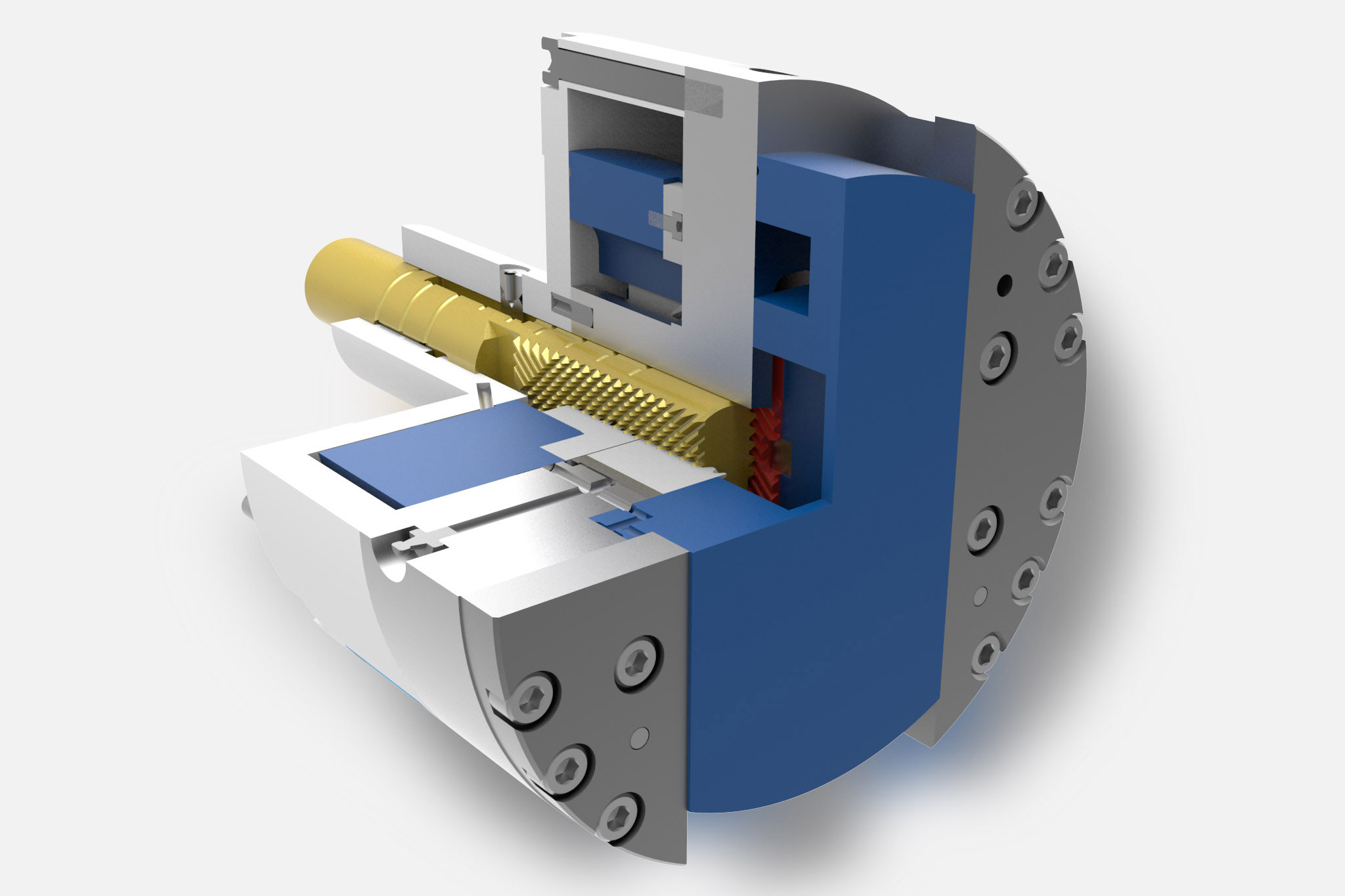

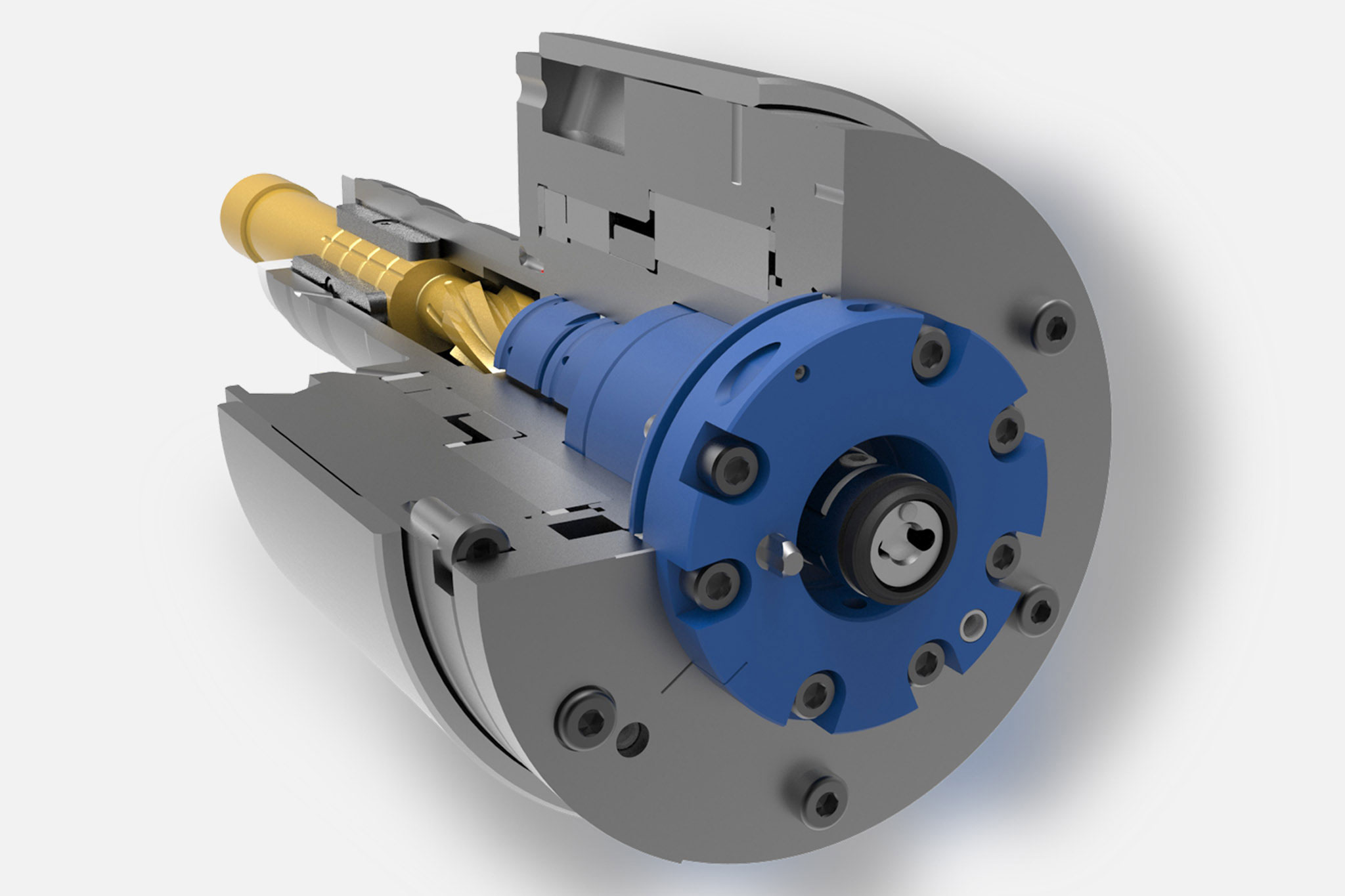

O sistema de ferramentas mecatrónicas TOOLTRONIC realiza movimentos de acionamento de forma simples e fiável tanto em centros de maquinação como em máquinas especiais. A maquinação de contornos, recessos e furos não cilíndricos é tão possível como circuitos fechados de controlo para compensação de corte ou a simples produção de grupo de peças de grande variedade.

O módulo de acionamento autónomo representa um eixo NC completo integrado no sistema de controlo de máquinas de nível superior através de energia indutiva e transmissão bidirecional de dados. Isto permite que toda a funcionalidade dos controlos modernos CNC seja utilizada em conjunto com o TOOLTRONIC.

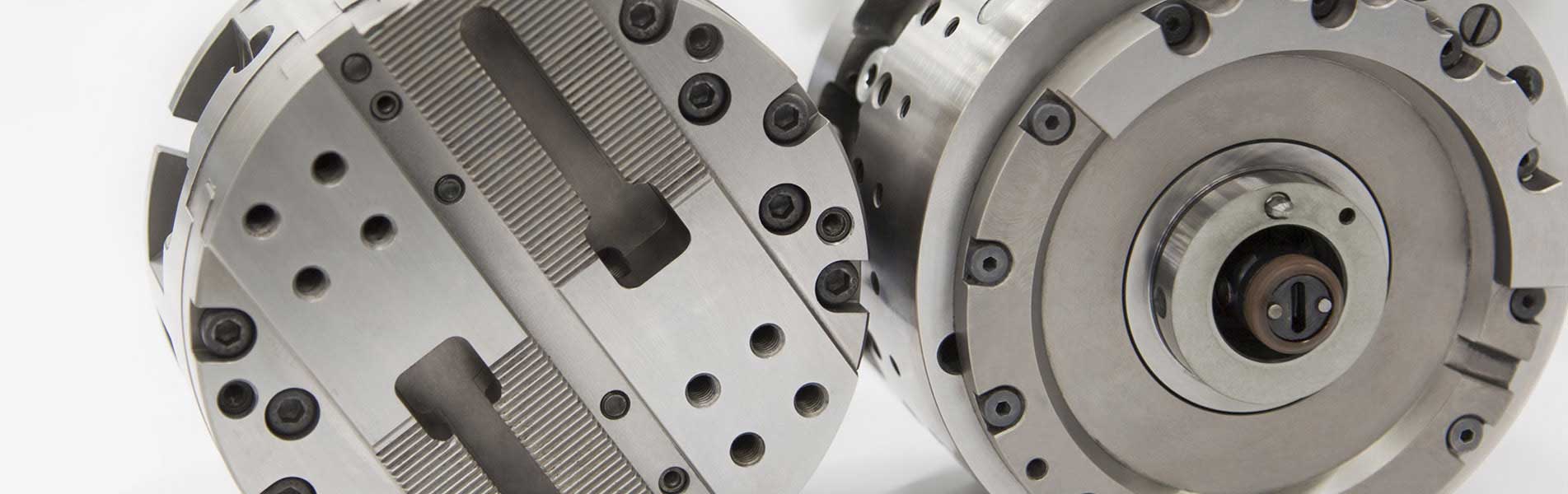

Dependendo da tarefa de maquinação, são utilizadas diferentes cabeçotes (saídas) da MAPAL na interface modular de TOOLTRONIC. As ferramentas de acionamento excêntrico (EAT) são utilizadas como padrão. As aplicações que requerem um grande curso com velocidade ajustada são processadas com ferramentas de acionamento linear (LAT).

O módulo de acionamento autónomo representa um eixo NC completo integrado no sistema de controlo de máquinas de nível superior através de energia indutiva e transmissão bidirecional de dados. Isto permite que toda a funcionalidade dos controlos modernos CNC seja utilizada em conjunto com o TOOLTRONIC.

Dependendo da tarefa de maquinação, são utilizadas diferentes cabeçotes (saídas) da MAPAL na interface modular de TOOLTRONIC. As ferramentas de acionamento excêntrico (EAT) são utilizadas como padrão. As aplicações que requerem um grande curso com velocidade ajustada são processadas com ferramentas de acionamento linear (LAT).

フェーシングヘッド

フェーシングヘッドは、主に専用機で大量生産を行う際に面旋削やリセス加 工、輪郭加工の目的で使用されます。このスライドツールの操作やツールホ ルダー、インサートの動作は、スピンドルドライブまたはフィードユニットの 背面にあるNC制御の横送り装置を介して行われます。