01.10.2018

More precision in the setting room

The right level of service for presetting devices will increase the productivity

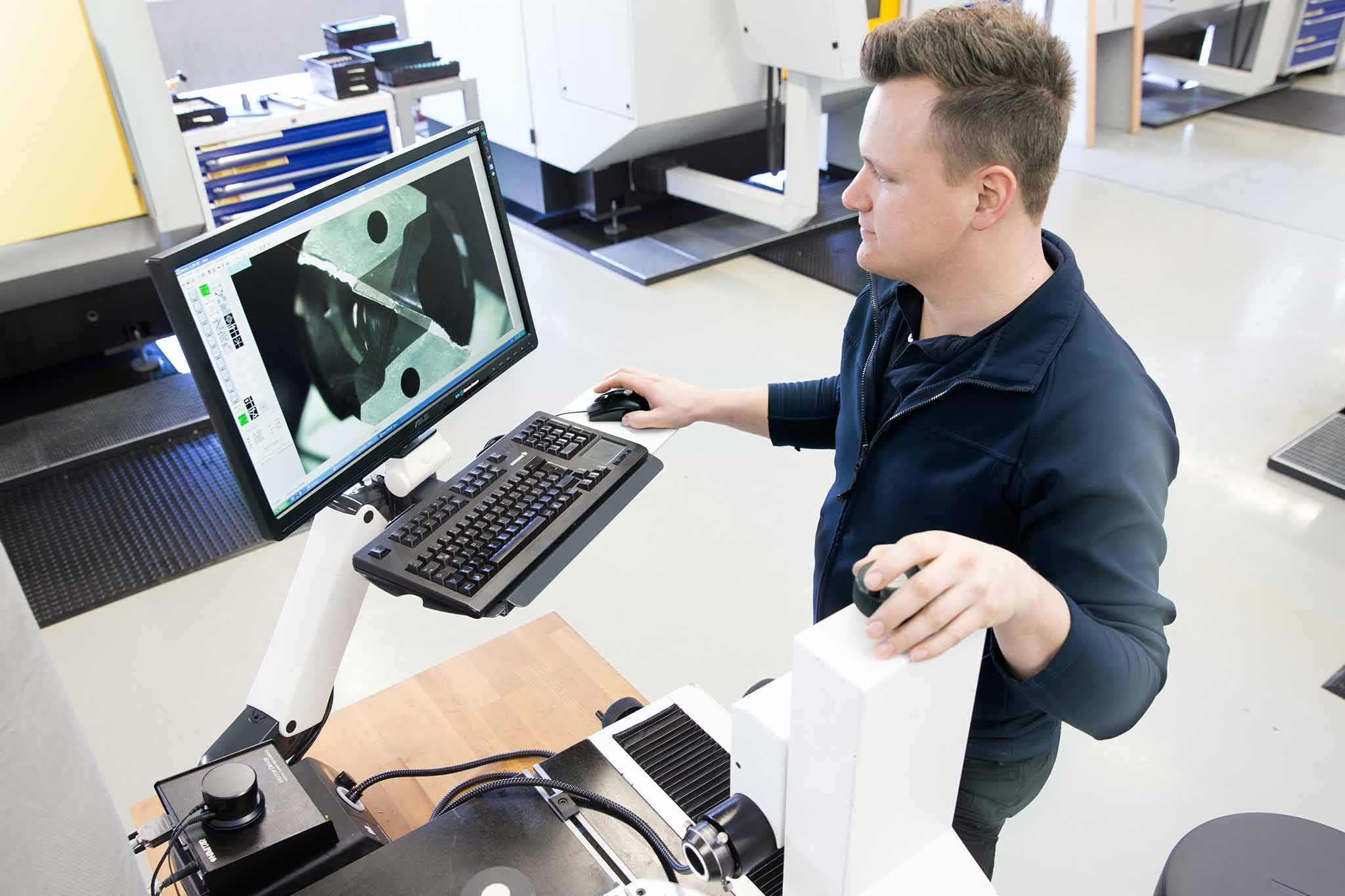

Many companies rely on MAPAL when it comes to evaluating processes and reducing running production costs. In addition to the complete range of precision tools, MAPAL focuses on the setting room in order to increase productivity with powerful and innovative setting and measuring devices, among other things. Because only precisely measured and set tools achieve reliable and precise results and reduce machine downtimes.

“Maintenance and calibration procedures do not only increase the service

life of the device, but also consistently improve precision and process

reliability to the level of a new device. Given the importance of the setting

fixture in the production process, regular service is a logical consequence.”

the setting fixtures. The newly defined service packages are now presented

to customers in a personal conversation and tailored to their specific needs.

“We want to take a much more active approach to the service area for

setting fixtures worldwide,” emphasises Jakob. “We explain the advantages

of a preventive service to our customers in detail. In order to not only offer

the quality of customer service, but also to be able to supply it, we are currently

conducting intensive training courses for our service technicians in

addition to building up personnel capacities.” The services are divided into

two categories: “Creating precision” and “Ensuring precision”.

Fast operational readiness: Creating precision

possible, various preparatory work must be carried out, which MAPAL specialists

can easily undertake. The commissioning of hardware and software

components is top priority. The connection and alignment of the device are

as much a part of the service as the definition and reporting of measurement

and setting data and basic instructions for the users. The measuring

instrument capability test provides a guarantee and certainty regarding the

required precision and tolerances to be complied with. Existing tools and

corresponding measurement programs can also be created by MAPAL employees

to accelerate the availability and use of the setting fixture. Finally,

MAPAL offers training and further education for various target groups and

requirements in order to ensure efficient work.

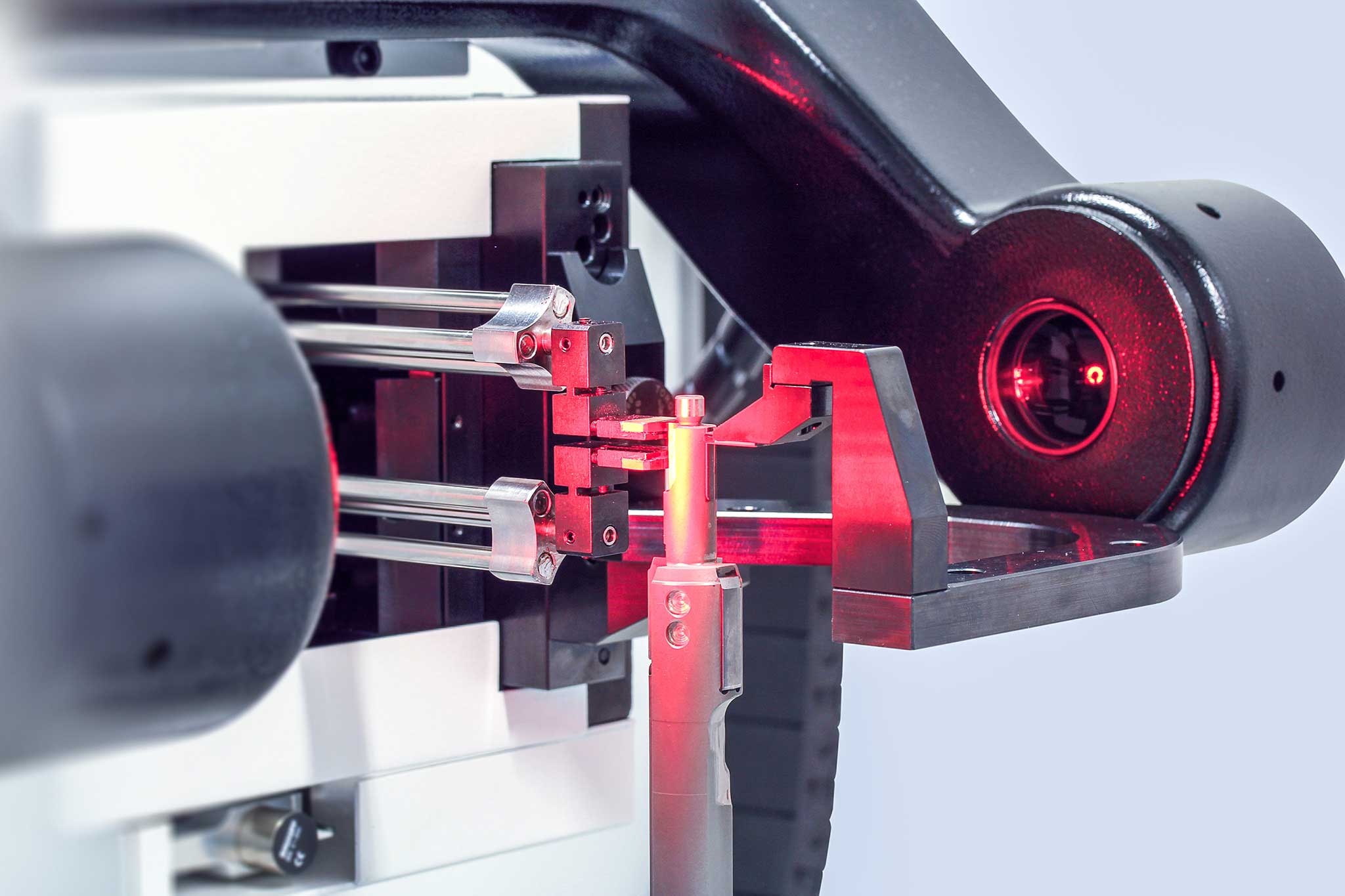

Lasting process capability: Ensuring precision

for this area. During annual maintenance or calibration of the setting

fixture, all relevant features are carefully checked and calibrated; wear

parts get replaced and software updates are carried out. Time can be saved

by optimising the measuring programs. MAPAL employees provide support

with know-how, update the factory data and install new tools. The modernisation

of setting fixtures also contributes to lasting process reliability.

Setting fixtures from MAPAL have a largely modular design and can be

modernised by re-tooling. This ensures that the state of the art is always

available. With the expanded capacities in technical support for setting fixtures,

maintenance can be performed without complication as a response

to user questions both on site and remotely by telephone.

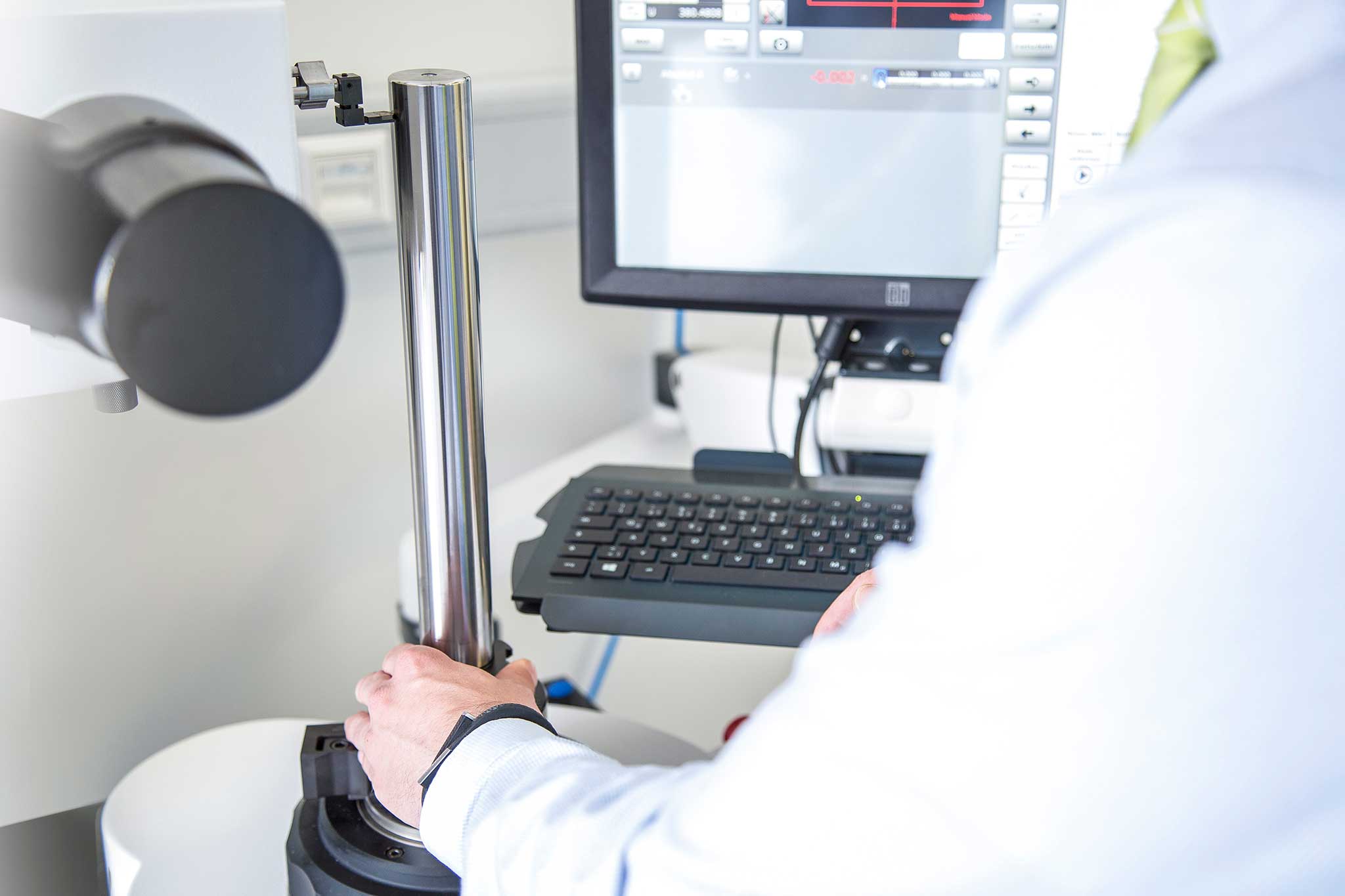

MAPAL provides the right setting

tolerances around the clock in order to guarantee reliable production.

MAPAL’s services, which will be presented at AMB 2018, stand for sustained

precision, full functionality and safe handling of the fixture by the customers’

employees.