15.05.2020

Lowering costs with sophisticated tool solutions

MAPAL tools demonstrate their streamlining potential throughout their entire service life

At less than ten percent of the total operating costs, the cost of procuring tools in cutting manufacturing might not initially appear to be a significant lever in rationalisation measures. Nevertheless, it is worth analysing the influence of tools and optimising both their immediate costs and costs that are indirectly aected by them throughout the entire manufacturing process. MAPAL has consciously chosen an approach that takes the total costs into account: “Tool-related costs have a significant impact on the overall costs”, points out Siegfried Wendel, Senior Vice President of Global Sales at MAPAL. “For this reason, it is worth focusing less on the simple purchasing costs of individual components, and more on the costs of the process time, when choosing a tool concept. And, as well as this, on the impact of the tools on the overall costs. So our products aren’t optimised for the cheapest sales price, but to continue delivering benefits throughout their entire service lives.”

How do tools impact overall operating costs?

Annual savings of 83,000 euros with a combination tool

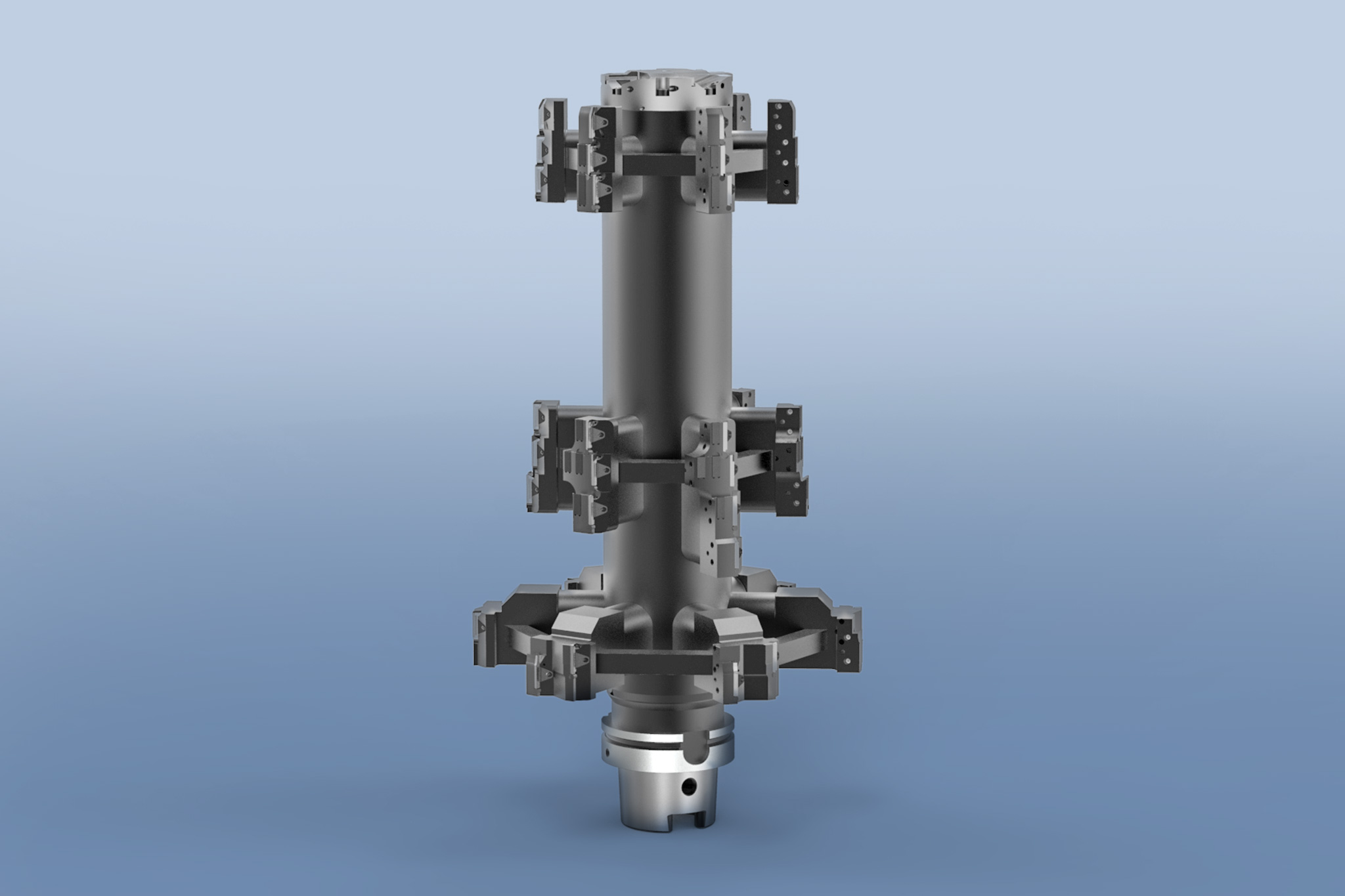

Combination tools are the classical example for a direct reduction in operating costs. This is

demonstrated in the following example from the car industry: A transmission housing made of the cast aluminium alloy AlSi9Cu3 was machined on a standard machining centre with a hollow shank taper connection. More specifically, the process involved the drilling of recesses in the variable valve timing (VVT) system. The most important concern was the accuracy of the large diameter during cutting. The shape is pre-cast, requiring a stock removal of 2 – 4 mm. There is no pre-machining. In terms of tool design, the customer’s aims were

- to carry out the machining with as few tools as possible

- to increase productivity by combining tools

- to simultaneously maintain maximum weight and moment-of-tilt requirements

Due to its thin walls, the part was prone to vibration during machining. In combination with extreme length-to-diameter proportions, complicated shape characteristics, necessary control cuts, and tolerances in the IT6 range, the machining process placed high demands on the tool technology.

In contrast to the competition, MAPAL was able to achieve the machining with just one combination tool. With the tool’s lightweight construction, the weight and moment-of-tilt requirements are not a problem. The cycle time is also reduced; the annual production time saved amounts to a total of 833 hours. Based on machine operating costs of 100 euros per hour, the operator saves over 83,000 euros annually.

Higher machine utilisation, reduced tool costs, greater process reliability

The machining of the tube sheets for shell and tube heat exchangers demonstrates how tool design can have an impact on process reliability costs. The tube sheet forms the end of the bundle of tubes in the heat exchanger. Depending on the size of the heat exchanger, it may have a large number of bores – often as many as several hundred. In order to ensure that the fluid medium does not escape at the point of connection between these parts, the bores have high positional and dimensional accuracy requirements. Because of the tolerance requirements and the cost of solid drilling operations, the choice of tool has an especially high impact here.

MAPAL’s three-bladed TTD-Tritan replaceable head drill demonstrates its full potential in this application. Due to its limited use of cost-intensive solid carbide, the replaceable head system represents resource e¡ciency and reduced inventory costs. At the same time, it achieves the performance level of a solid carbide drill. For this application, every machining diameter is required at multiple lengths. In this case, the separate provisioning of drill heads and tool holders has a further positive impact on inventory costs.

For example, the TTD-Tritan achieves significant improvements compared to the previously used double-edged tool from a competitor when machining tube sheets made of SA-516-70N high-carbon steel with a diameter of 25.6 mm and a bore length of 63.5 mm. The replaceable head drill reduces machining time by 57 percent: the MAPAL tool needs only 29 minutes to complete 550 bores. These benefits are a result of the TTD-Tritan’s 59 percent higher feed rate on the one hand and an improvement of the process on the other: users no longer need to pilot or subsequently clean the part. In addition to this, the TTD-Tritan improves the direct machining costs, as the three-bladed replaceable head drill has a 90 percent longer tool life than the competing tool.

Overall operating costs reduced by eliminating a setting process

The main fields of application for tools with guide pads are reaming and fine boring applications

with extremely high shape and position tolerance requirements. The advantage of these tools is that diameter and back taper of the precision blades can be set with micrometre-accuracy.

However, the necessity of setting the diameter and back taper of the blades is also a disadvantage. These setting processes take time and expertise on the part of the operator. MAPAL has developed the EasyAdjust system to take this additional effort into account. A high-precision adjustment system with a cassette and pre-set back taper replaces one of the two setting processes. Accuracy is retained and handling is simplified.

Take, for example, the application of an external reamer with an internal diameter of 75 mm

equipped with the EasyAdjust system. In this case, the reamer machines pins on planetary

carriers made of heat-treated steel. At a diameter of 75 mm, the pins have a tolerance of 18 »m. The maximum permissible deviation of the cylindrical form is just 5 »m. The potential of the EasyAdjust system is particularly apparent in the case of external reamers. The adjustment controls on external reamers are di¡cult to access, making the setting process even harder. As a result, not having to complete the back taper adjustment makes a big difference. The high accuracy combined with an economical, four-bladed TEC indexable insert ensures the maximum cost-effectiveness of the machining: The external reamer operates on a machining centre at a cutting speed of 120 m/min and a feed rate of 60 mm/min. In this scenario, one cutting edge can machine 470 pins. A new indexable insert is only required after 1,880 pins.

Digital services reduce overall operating costs through reliability during production

By now, the advantages of digital connectivity are well-known. In cutting manufacturing, too,

digital possibilities have become an indispensable driving force in the overall operating costs. Nevertheless, the investment and start-up costs of digital services are often a hurdle for companies that carry out machining. Ultimately, their implementation in existing manufacturing processes often involves factors such as the need to modernise the available machinery or carry out new installations.

With c-Connect, the open-cloud platform c-Com offers a simple and economical way of networking machines. c-Connect makes it possible to digitally transfer tool measurement data from the setting fixture to the machine, registers inventory changes, and is able to monitor the machine status via various sensors and the c-Connect box. Simply, compatibly, and quickly. Operators benefit from cost-saving results immediately. Here are just some of the benefits:

- no chance of errors resulting from the manual inputting of tool data;

- information concerning the tools, such as their tool life, remains available after the tools have been removed;

- transparent data is available to all persons involved;

- machine downtimes are minimised.

Small decisions with a big impact

aim of achieving maximum cost-eectiveness for their customers. With 70 years of experience, a broad range of products, and a global presence, the precision tools manufacturer offers customers future-proof and technologically leading solutions: “When looking at the overall costs, there are a lot of ways in which our tools can make a difference. For that reason, our technical advisors always design the tools specifically for each individual customer – and oer a service warranty that we are able to fulfil optimally through our global service network”, emphasises Siegfried Wendel. “With the right technological partner at your side, completely new opportunities for cost savings become available.”