04.05.2023

News from the reaming and fine boring sector

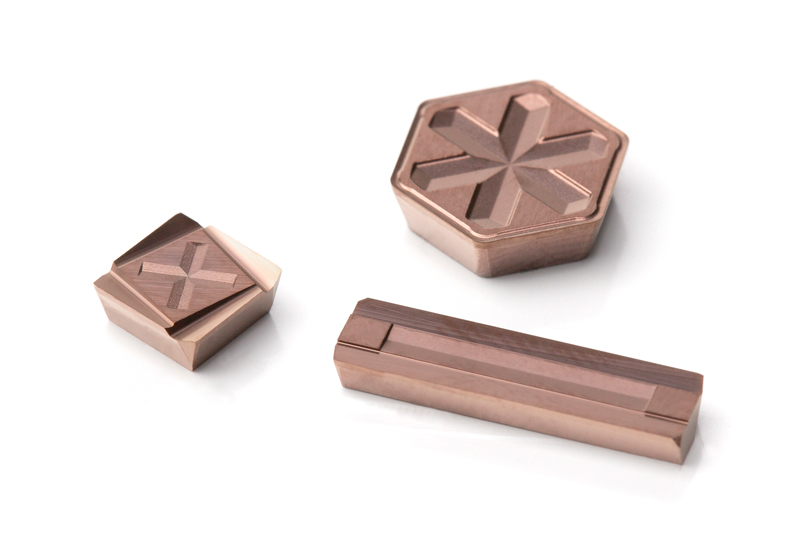

MN reamers with short delivery times, new cutting materials for special requirements

Die Mikrostruktur der PVD-Schicht ist feinkristallin, was hohe Härte mit hoher Zähigkeit vereint. Die Schneidstoffe sind thermisch sehr stabil und überzeugen durch eine hohe Warmfestigkeit und Schichthaftung. Um in Durchgangs- und Grundbohrungen eine optimale Oberfläche zu erzeugen, wird die PVD-Schicht im µm-Bereich abgeschieden. Damit behalten die Schneidkanten ihre Schärfe.

Zum Einsatz kommen die neuen Schneidstoffe zur Markteinführung unter anderem in den Reibahlen der MN-Baureihen von MAPAL. Diese Werkzeuge stehen für allerhöchste Genauigkeiten und können dank der neuen Schneidstoffe nun auch optimal zum Hartreiben sowie zum Reiben von Edelstahl genutzt werden. Sie funktionieren nach dem MAPAL Prinzip – mit einer Schneide und einer gegenüberliegenden Führungsleiste, die je nach Anwendung aus Hartmetall, Cermet oder PKD ausgeführt wird.

Kontakt

Kathrin Rehor Public Relations Kathrin.Rehor@mapal.com Tel.: +49 7361 585 3342