Large series with combination tools for highest requirements and productivity

Valve housing AlMgSi-T6

Initial situation at the customer

- Very high quantities

- High cycle time requirements

- High hourly rates

- High demand for process reliability

- High demands on quality of surface, shape and position tolerances

- Burr-free / scoring-free machining

Special features of this solution

- Ideal chip breaking due to special cutting geometries

- Perfect surfaces and contact ratios due to high-quality PCD finish tools (Rz = 1 μm)

- Combination tool for optimum process design and cycle time reduction

Tool highlights for pneumatic valve housings

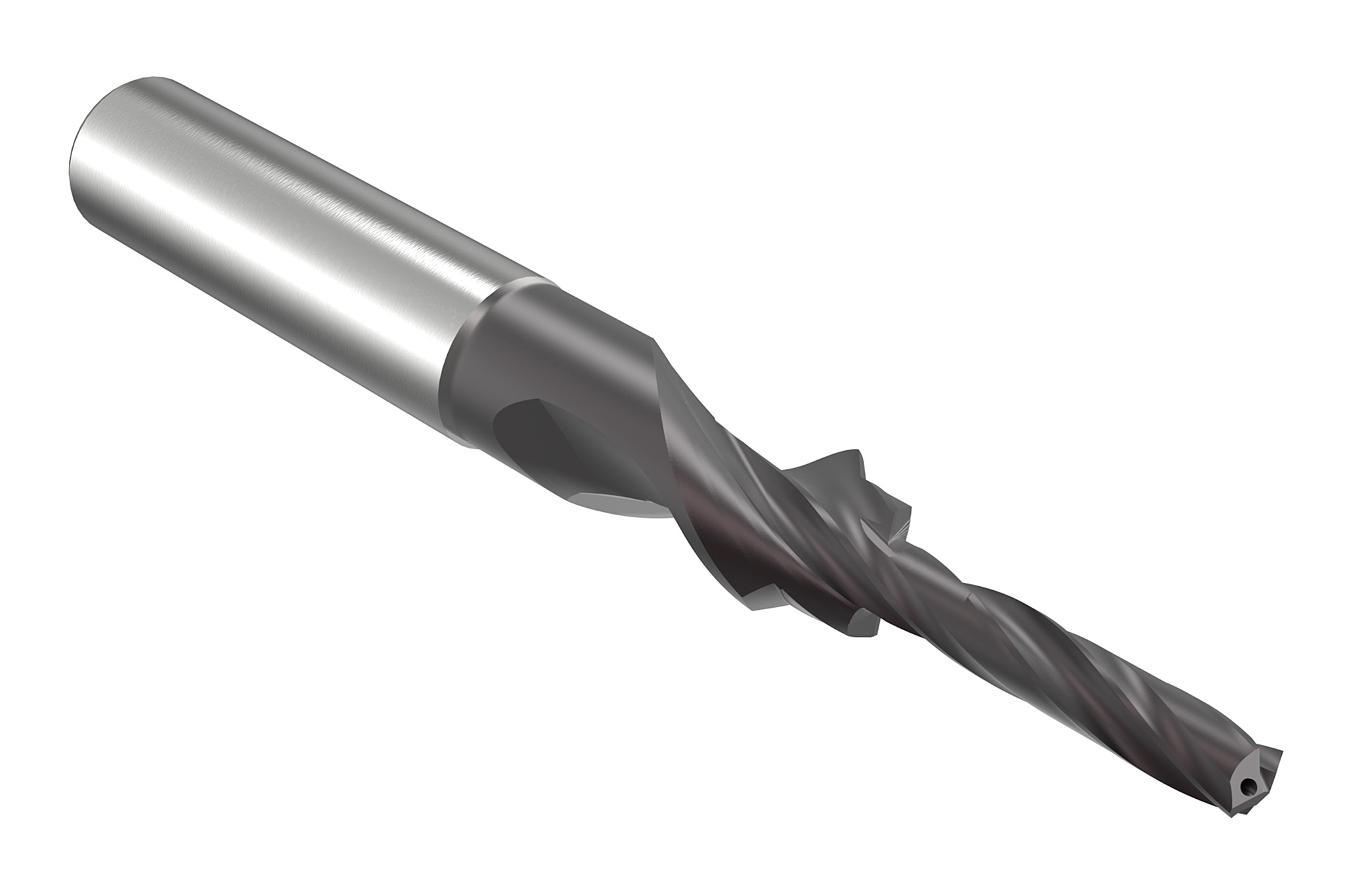

Stepped bores

- Solid carbide-multi-stepped tool with special multicut technology and chip guiding stage for ideal chip control and frequent re-grinding capability

Solution in one processing step for cone contours

- PCD step drill for the process-reliable machining of cone contours as solution in one processing step

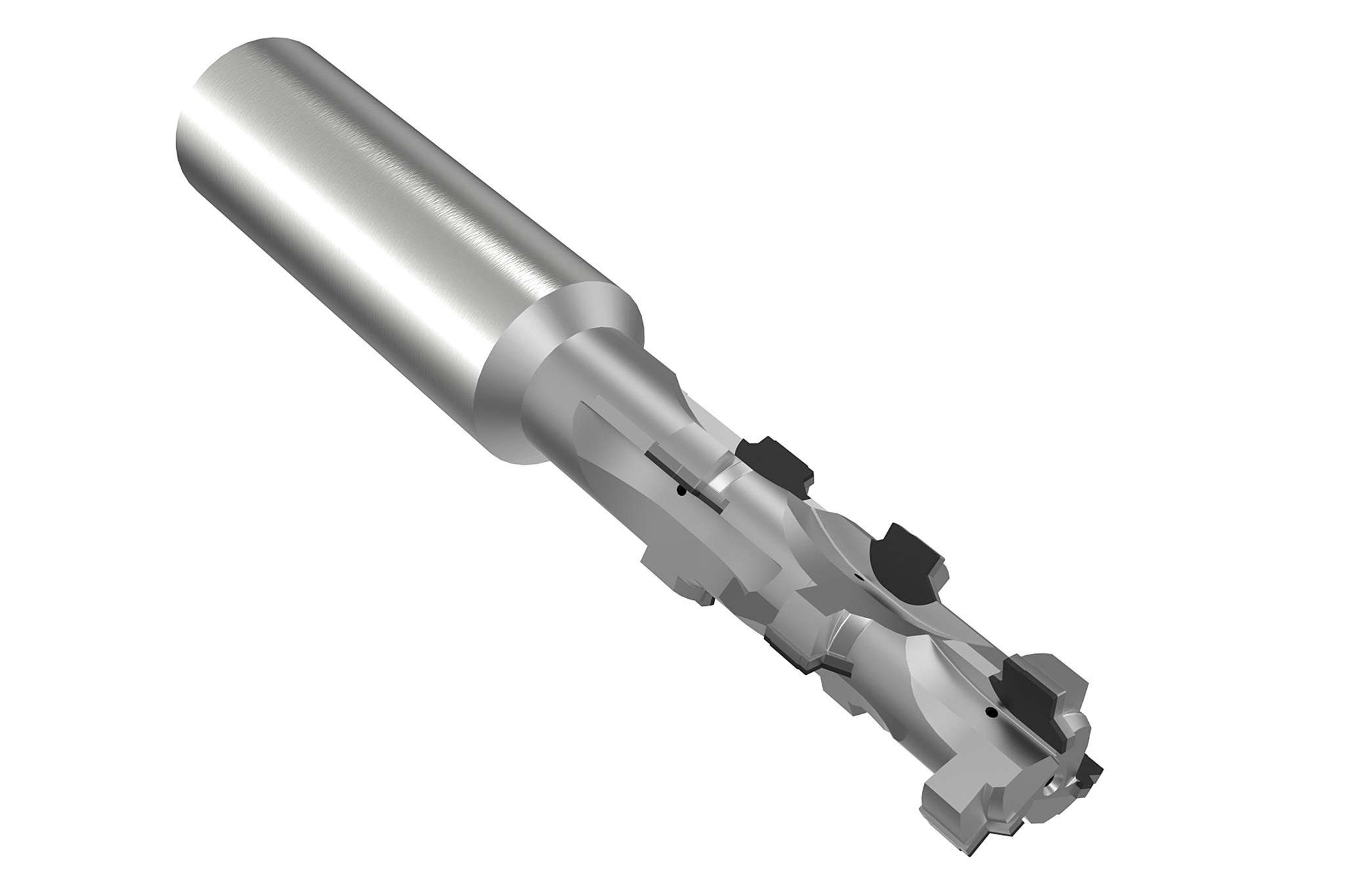

Contour machining

- Multi-stepped PCD combination tool

- Highest productivity as well as concentricity for highly complex contour machining

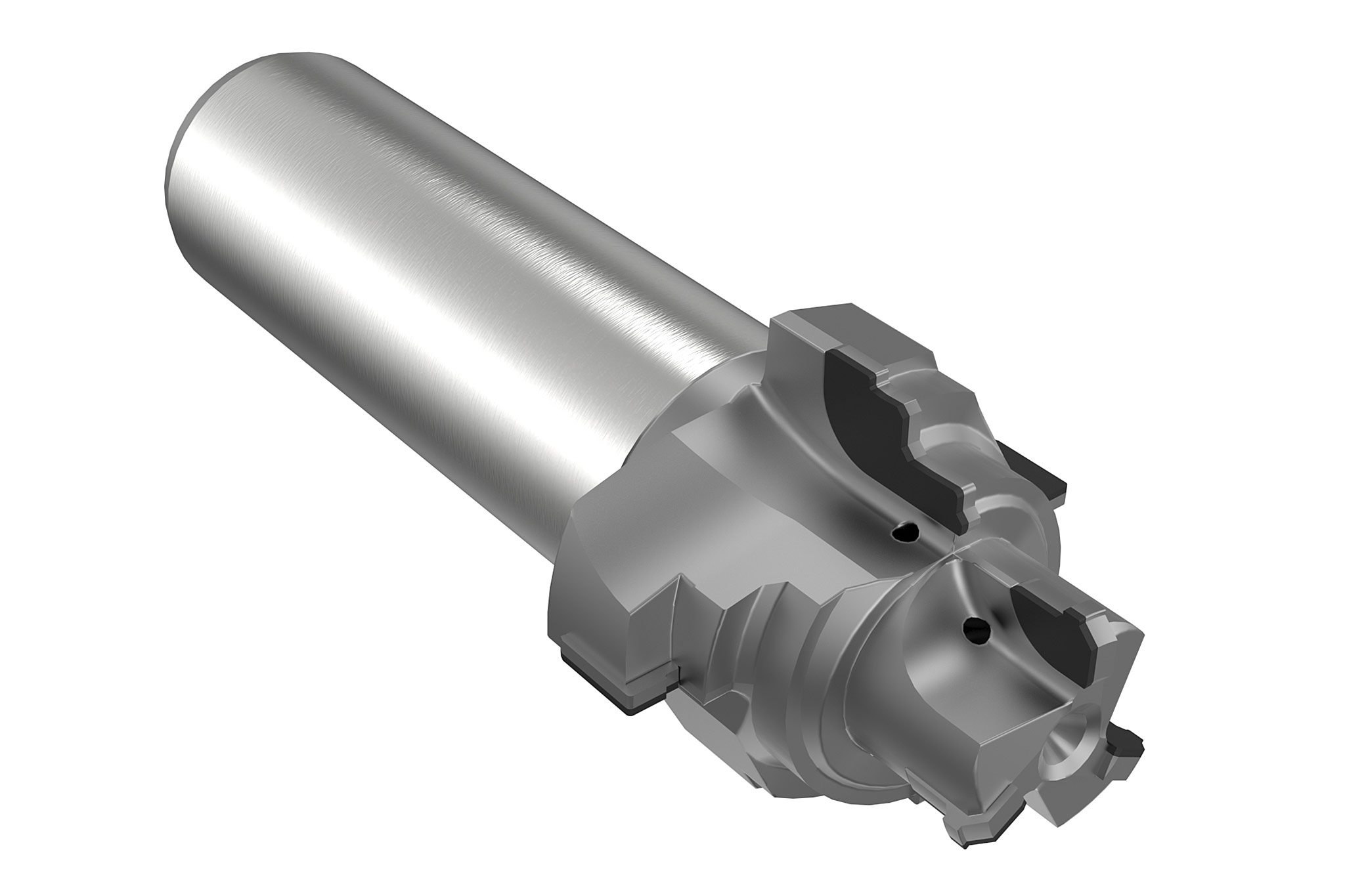

Control edge machining

- PCD circular milling cutter for highest surface finish and perfectly coordinated control edges

Advantages

- Precisely coordinated processes between pre-machining and finishing

- Reduced non-productive times

- Cycle time saving with increased quality

- High process reliability in series production

- The long-standing experience with regard to the development and production of PCD or solid carbide tools enables optimum process design, whatever the requirements