Compresor de espiral

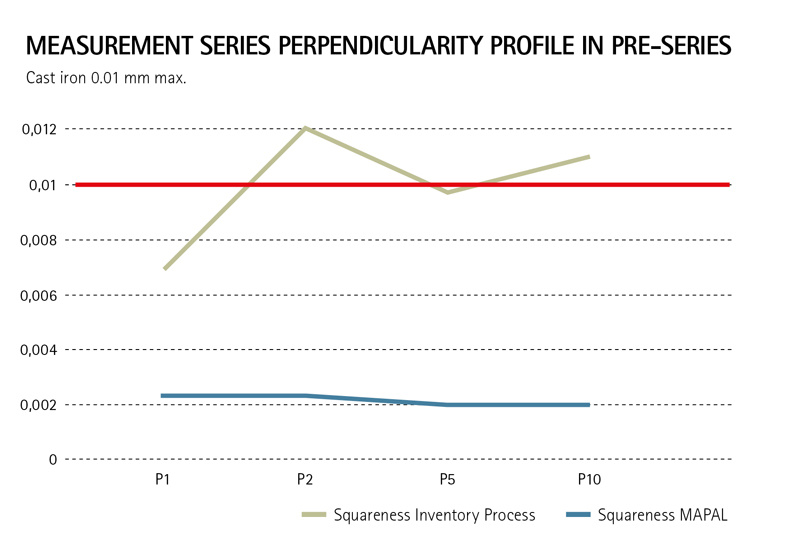

Espiral de EN AW-4032 (AlSi12,5) y EN-GJS-400-15

Situación inicial del cliente

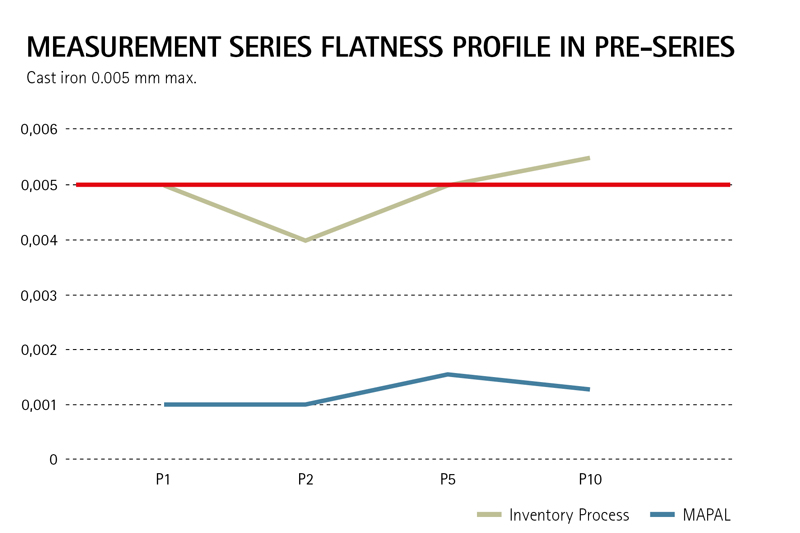

- Frecuentes reclamaciones de los clientes finales por variaciones en la calidad de los componentes al mecanizar los componentes de paredes delgadas

- Estado previo a la producción en serie de los componentes de espiral de hierro fundido

Particularidades de esta solución

- Frecuentes reclamaciones de los clientes finales por variaciones en la calidad de los componentes al mecanizar los componentes de paredes delgadas

- Estado previo a la producción en serie de los componentes de espiral de hierro fundido

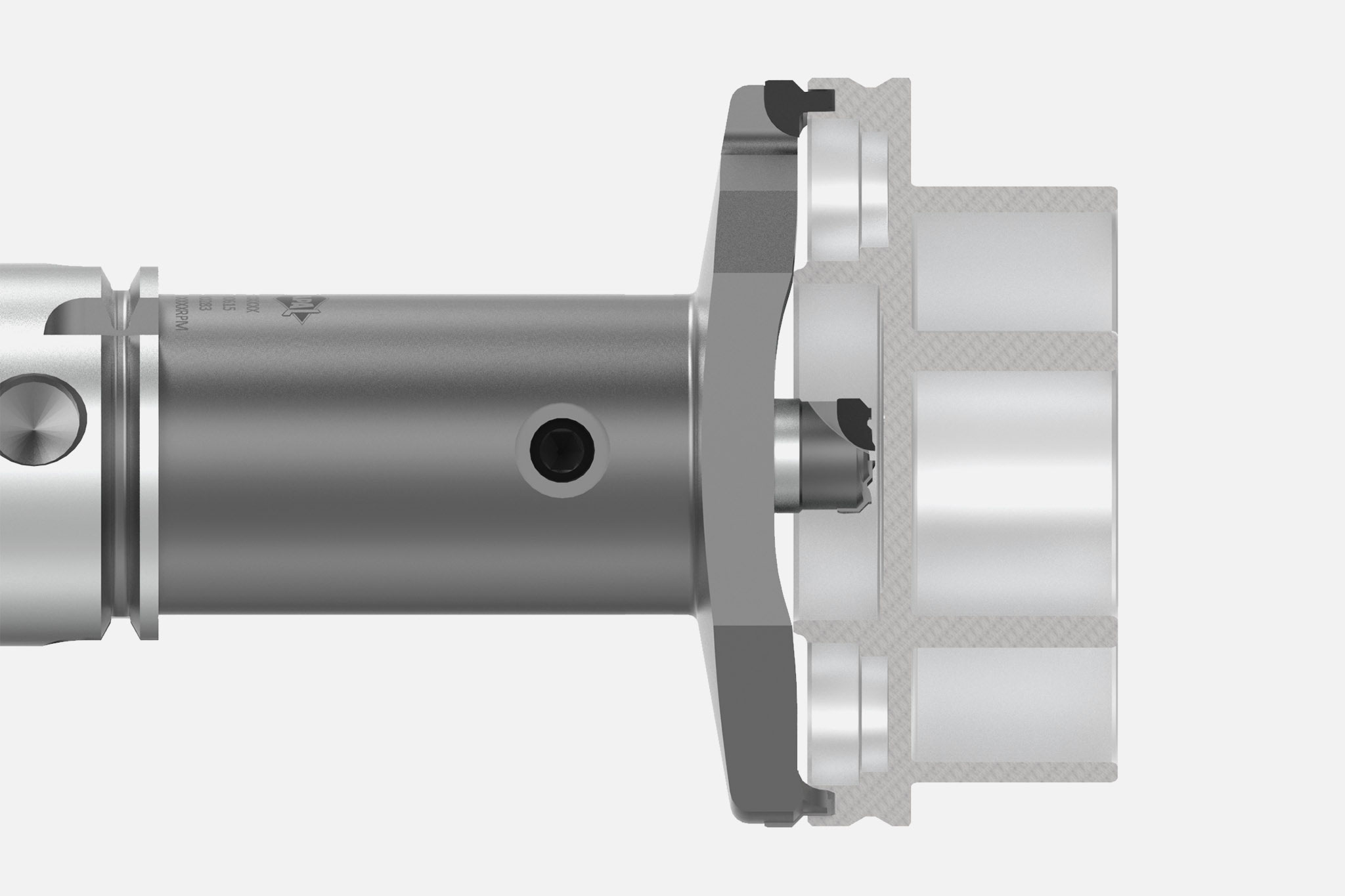

Espiral de aluminio

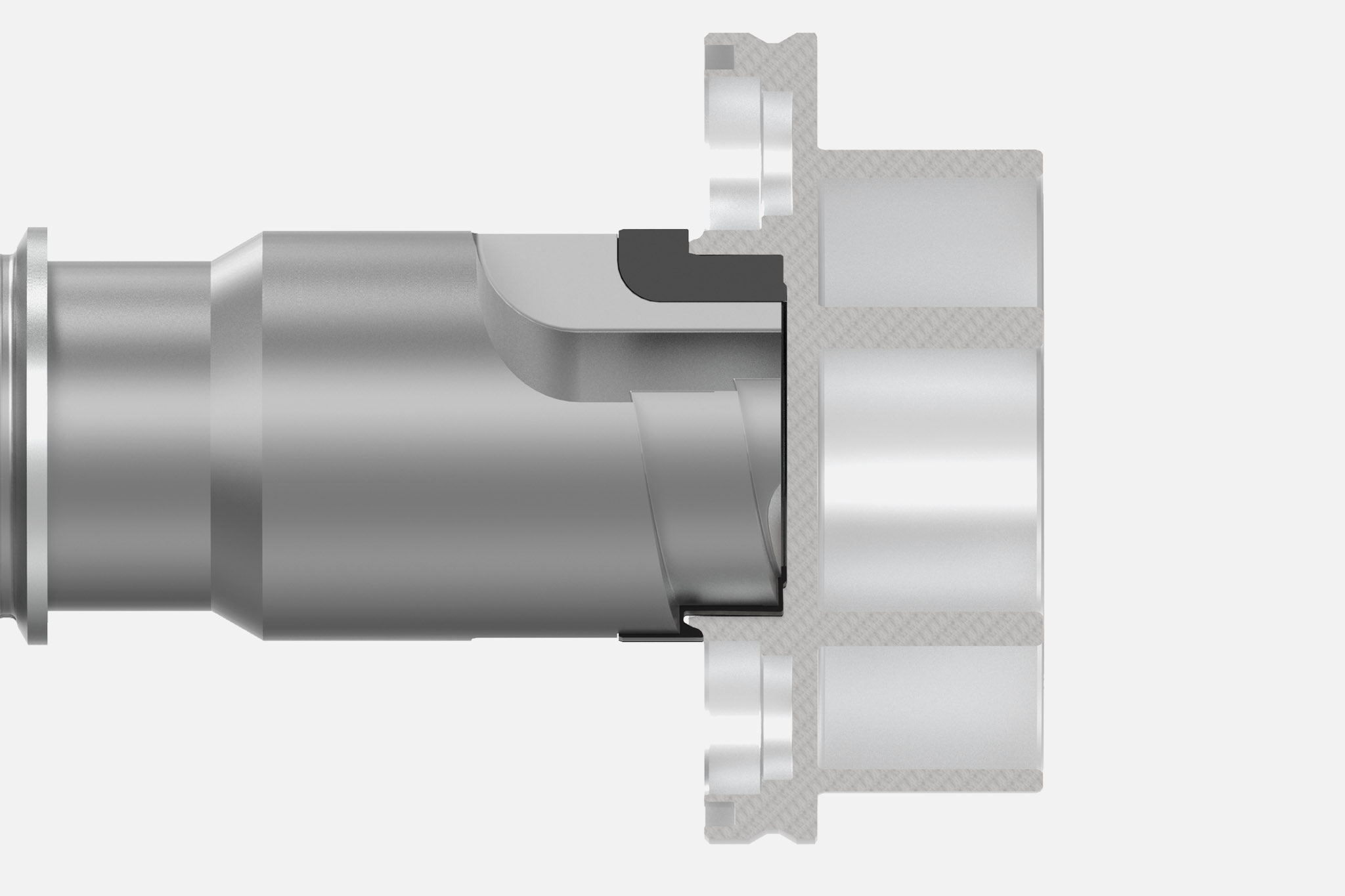

Espiral de metal fundido

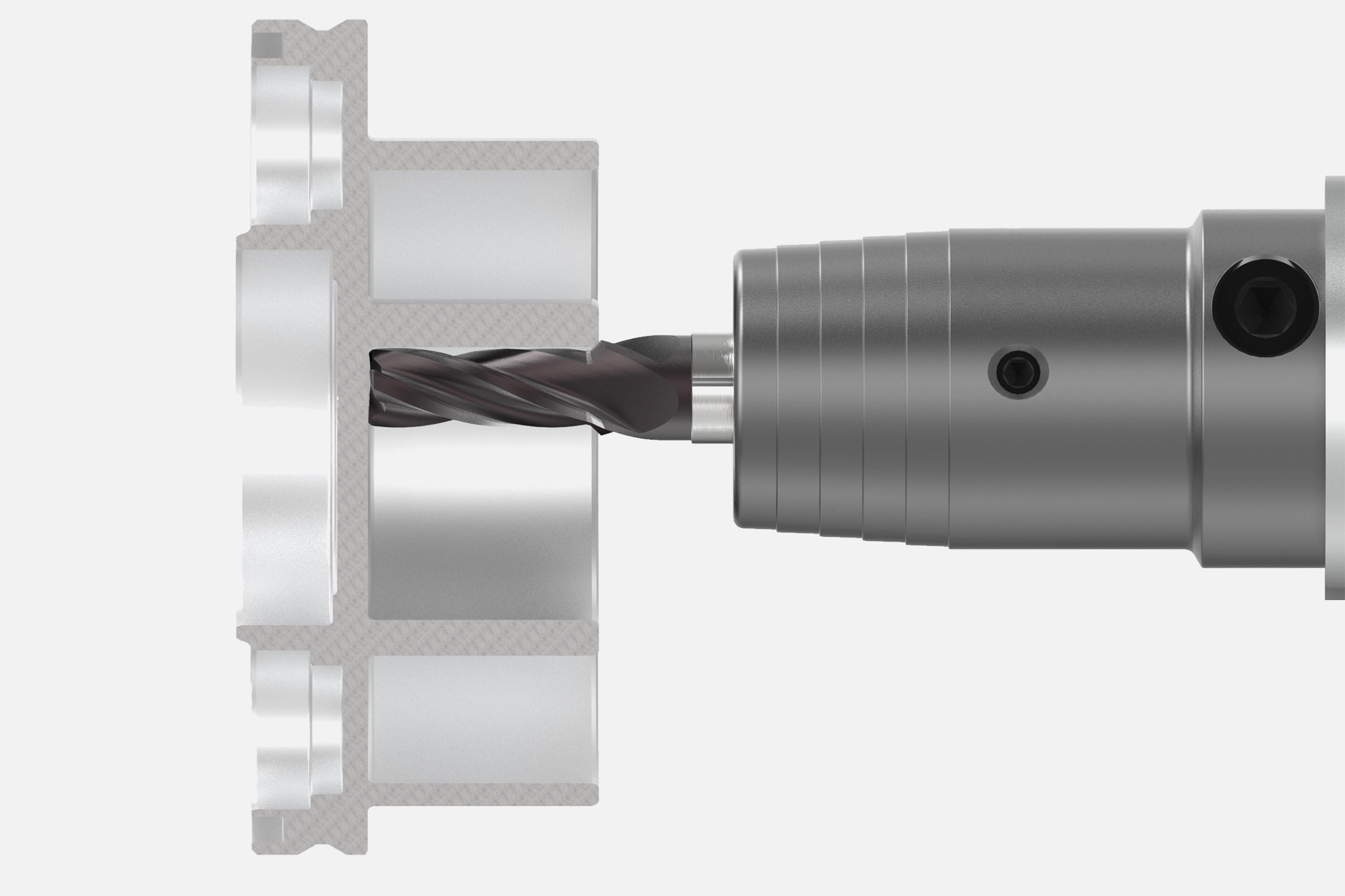

Pasos de mecanizado en el compresor de espiral

Ventajas

- Con la calidad permanente de los componentes se evitan las reclamaciones de los clientes y se reducen costos significativamente

- Claras ventajas competitivas por la cooperación con MAPAL y las experiencias de varios años de la competencia fundamental automotriz

- Mecanizado completo con seguridad de proceso en aluminio y hierro fundido, mediante supervisión intensiva en la producción en serie