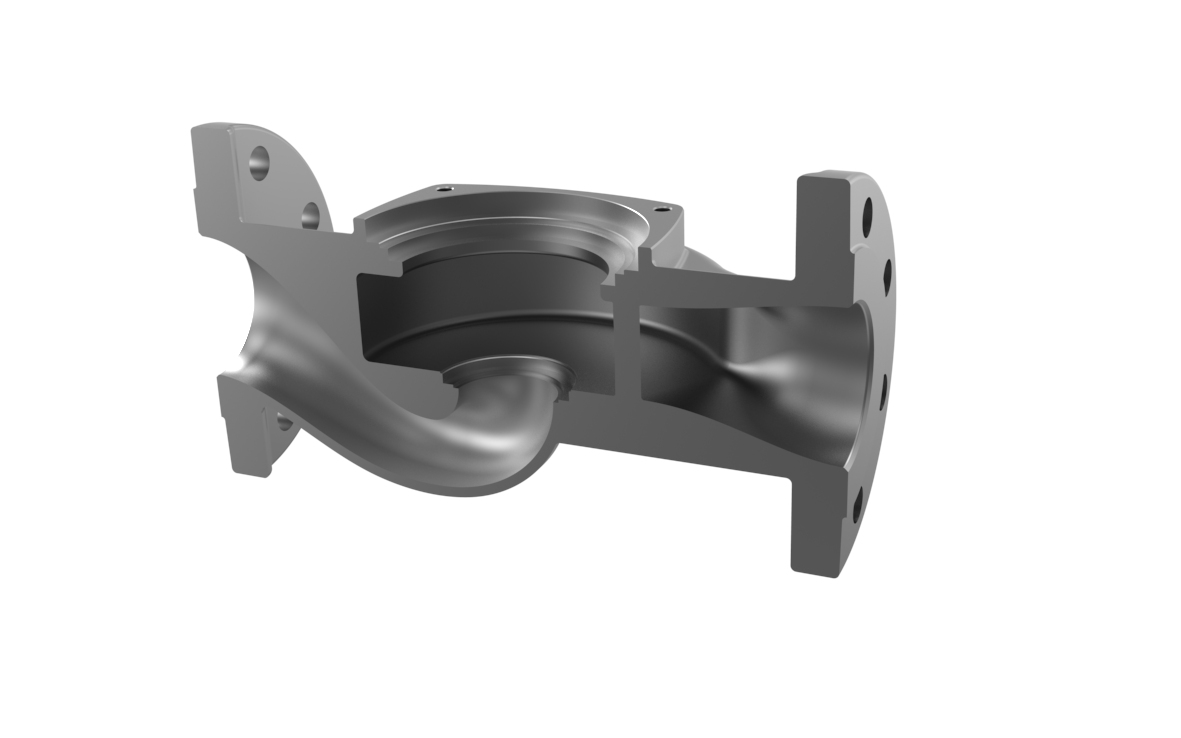

Carcasa de bombas de recirculación

Carcasa de la bomba EN-GJL-250 / 1.4301 (V2A)

Situación inicial del cliente

- Proceso poco flexible: Unidades de válvula de corredera plana en la línea de transferencia

- Los largos tiempos no productivos al cambiar las herramientas y el producto ocasionan la detención de las máquinas

- Exigencia: Breves tiempos de ciclo y de cambio de productos

- Se requiere un alto nivel de flexibilidad al mecanizar todas las variantes de componentes en una máquina

Particularidades de esta solución

- Posibilidad de realizar un cambio de herramienta automático

- Ajuste neutral de las herramientas con respecto al tiempo principal mediante herramientas hermanas

- El proceso flexible permite realizar un ajuste previo en el dispositivo de ajuste

- Cambio de herramienta rápido

- Posibilidad de utilizar herramientas estándar (p. ej. taladro o fresa) en el mismo husillo

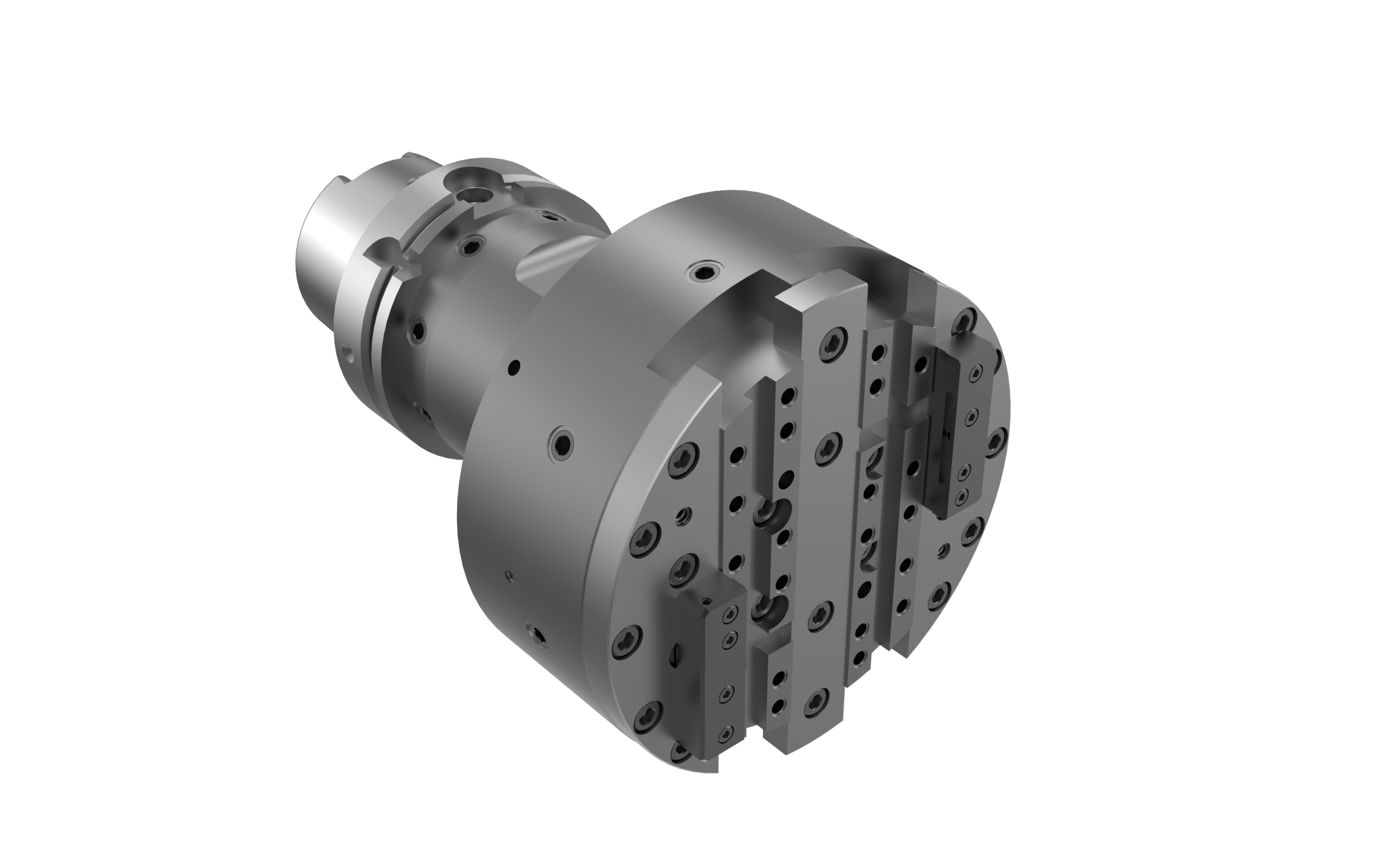

- Tecnología de insertos de corte intercambiables para bajos costos de material de corte

- Se reducen los tiempos de ciclo con z = 2 respecto al mecanizado en tornos

Herramientas destacadas

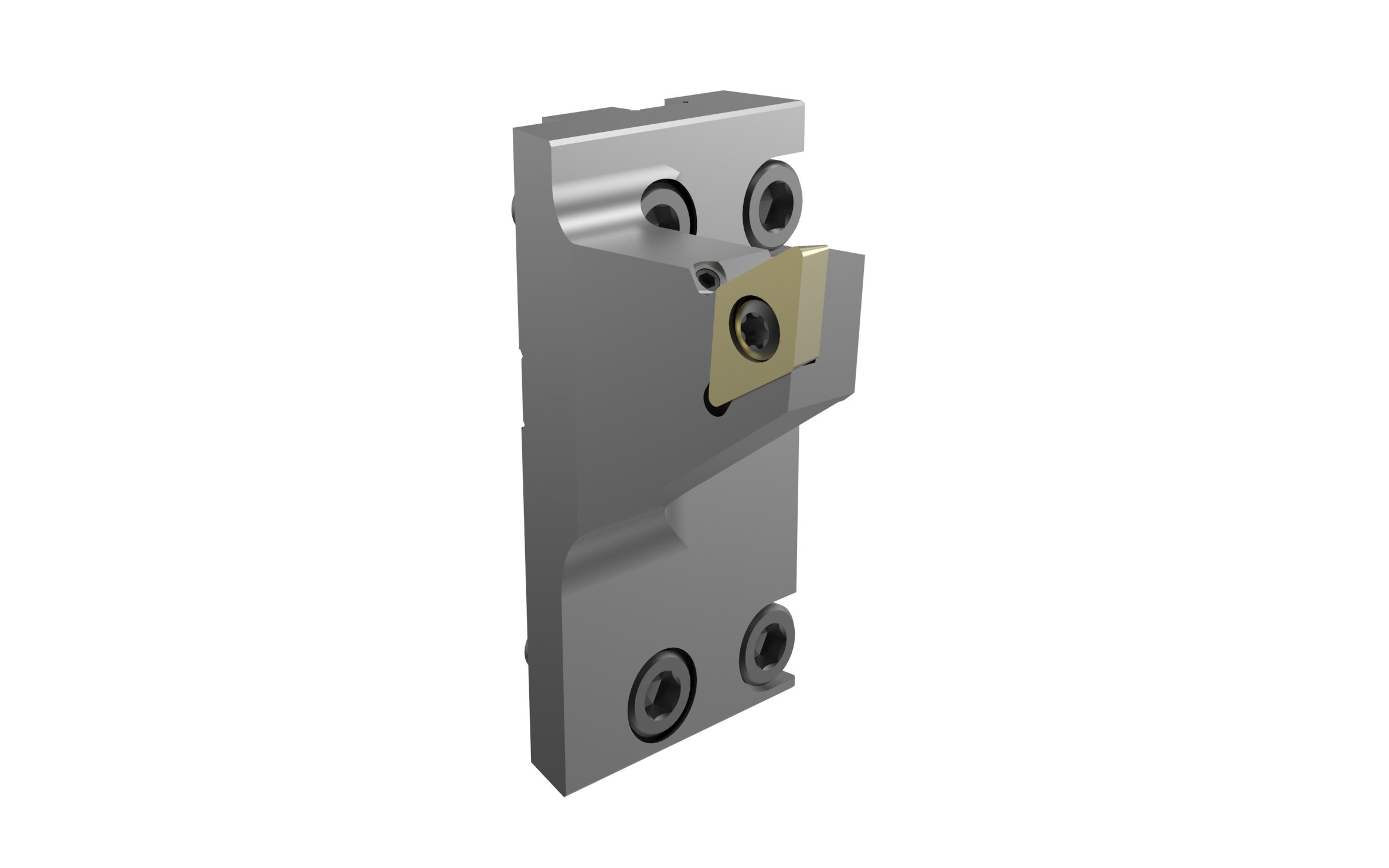

Herramienta de control para sistemas de eje U

- Las herramientas superpuestas flexibles permiten cubrir todas las variantes de componentes en la aplicación con solo cuatro tipos de herramientas

- El sencillo cambio de los insertos de corte intercambiables permite el mecanizado de diferentes materiales

- Máxima flexibilidad por interfaz HSK intercambiable y colocación en el depósito de herramientas

- Diseños con corredera sencilla y doble

- Posibilidad de utilizar herramientas hermanas

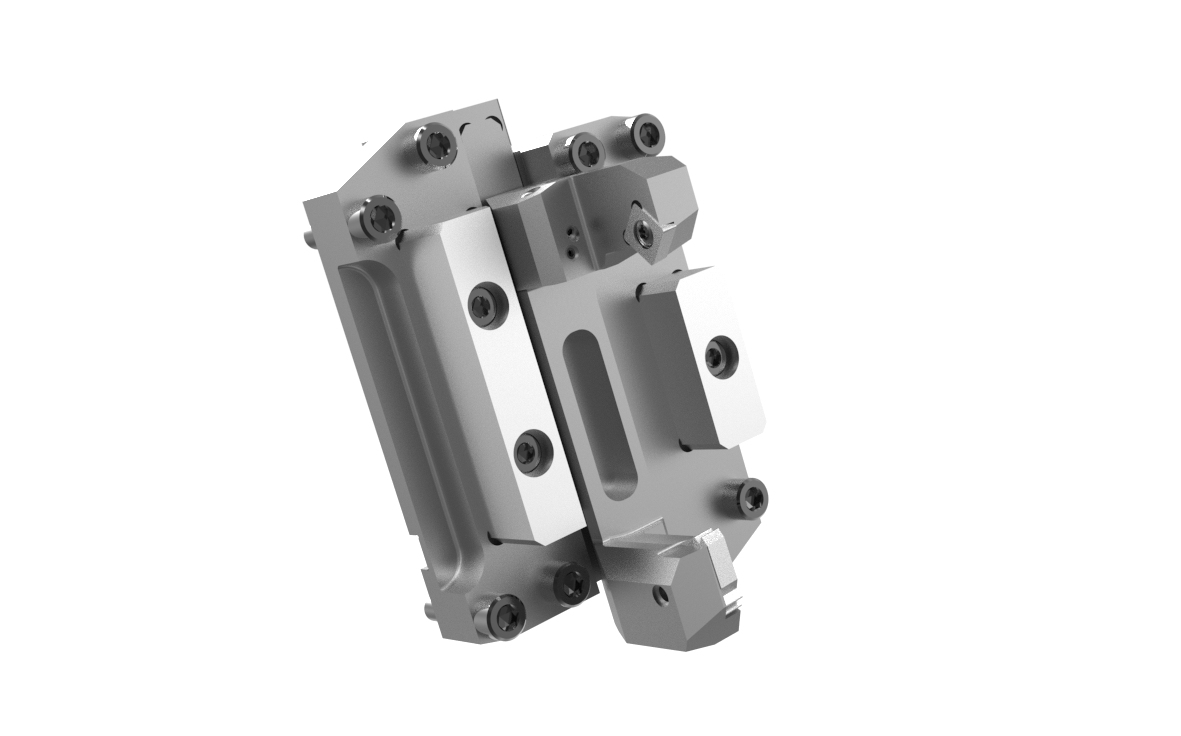

Contorno interior y mecanizado de refrentado

Contorno exterior y mecanizado de roscas

![DOWNTIMES [MIN.] FOR PRODUCT CHANGES](/medias/sys_master/root/he9/h05/9687965368350/EN__Diagramme/EN-Diagramme.jpg)

Ventajas

- Reducción de los tiempos de inactividad durante el cambio de productos e insertos

- Grandes ahorros en los costos de la producción en serie

- Solo se requiere un tipo de cabezal de refrentado con herramientas superpuestas intercambiables para toda la gama de productos

- Puede realizarse en todas las máquinas con eje U o accionamientos Tooltronic®.

- Posibilidad de realizar todo el mecanizado en una máquina y con una configuración de sujeción

![DOWNTIMES [MIN.] FOR CUTTING EDGE CHANGES](/medias/sys_master/root/ha8/h09/9687965499422/EN__Diagramme2/EN-Diagramme2.jpg)