25.07.2019

Higher Surface Quality through Vibration Dampaning

Vibrations often occur during machining. This leads to dynamic instability of the system and cause a multitude of failure potential. MAPAL's innovative system for vibration dampening increases surface quality significantly.

Inadequate surface finishes, insufficient accuracy, high machining noises, shortened tool lives and, in extreme cases, broken tools and cutting edges can be the result.

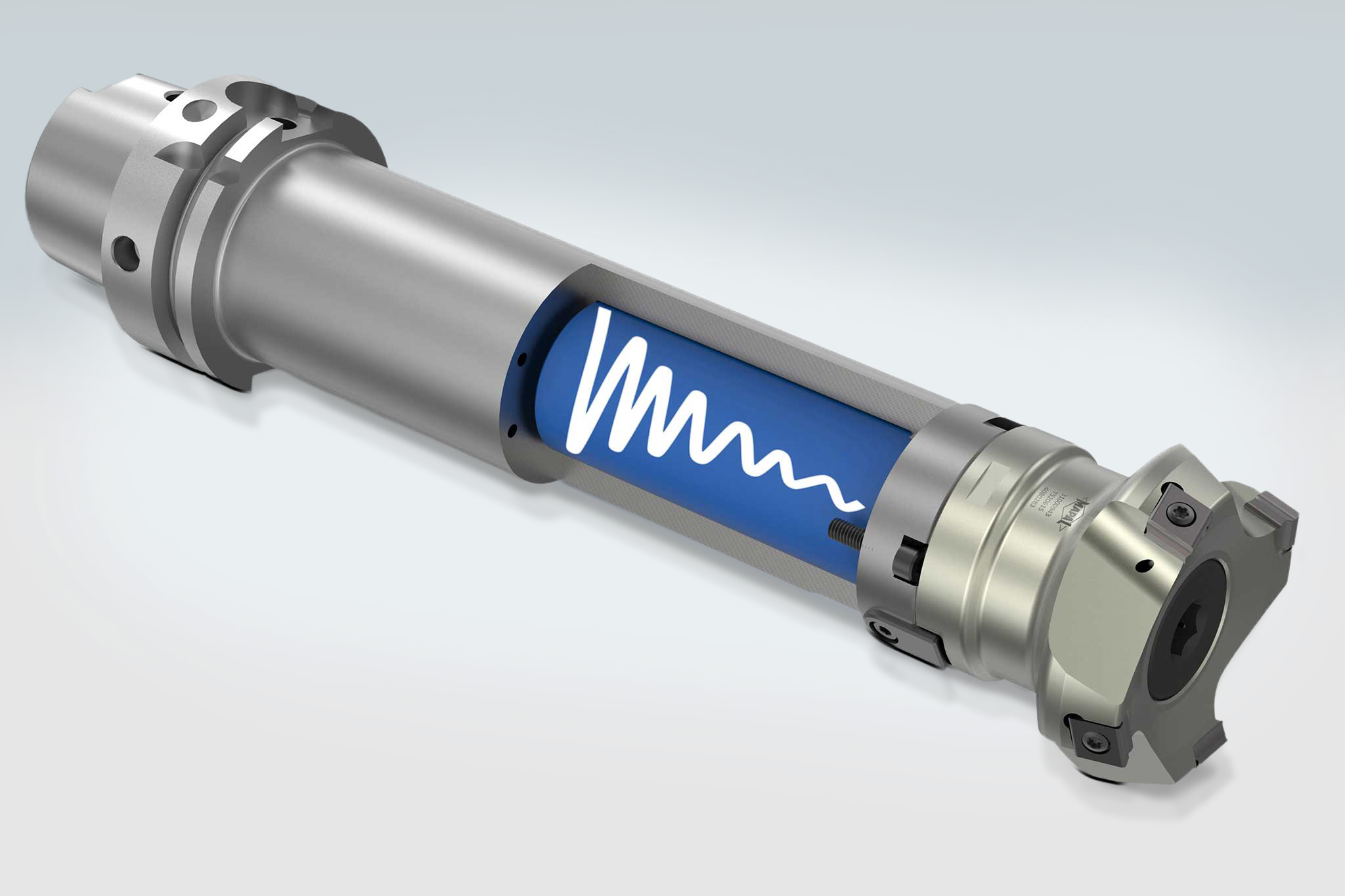

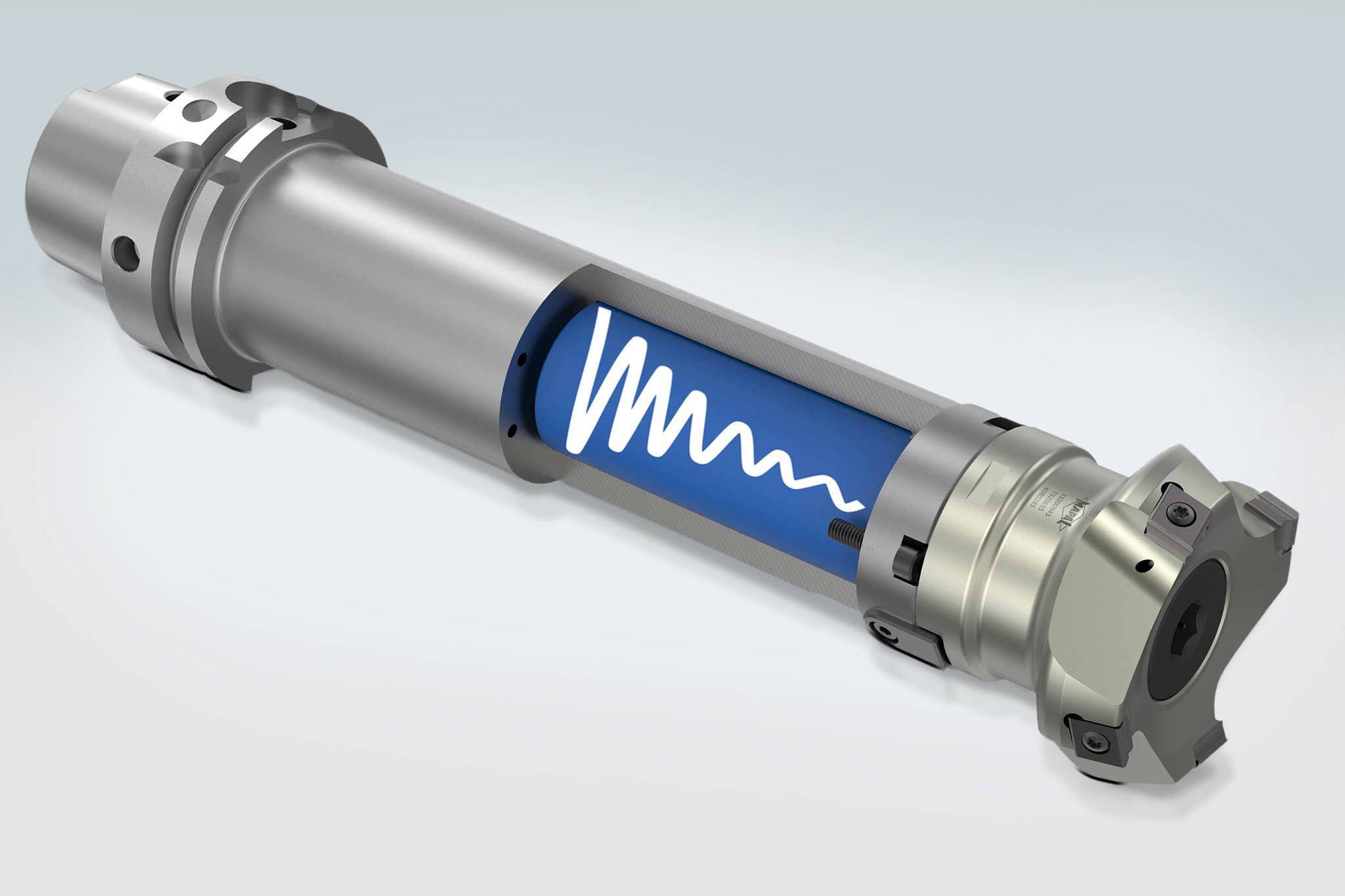

In order to minimise these vibrations and their consequences, MAPAL has now developed an innovative system for vibration damping in the tool shank, as particularly tools for boring and milling with very long projection length tend to vibrate due to an inadequate dynamic rigidity of the overall system.

Higher Cutting Speed, Significantly Higher Service Quality

The self-contained system of auxiliary mass and several steel spring packages counteracts the deflection of the tool body and minimises it. The vibrations can be up to 1,000 times lower compared to tools without absorber system. Despite the long projection length, quiet, stable running is achieved. This makes it possible to work at higher cutting speeds and significantly increases the material removal rate. In addition, significantly better surface finishes are achieved thanks to vibration damping.

Rz value was halved from 7.8 µm to 3.9