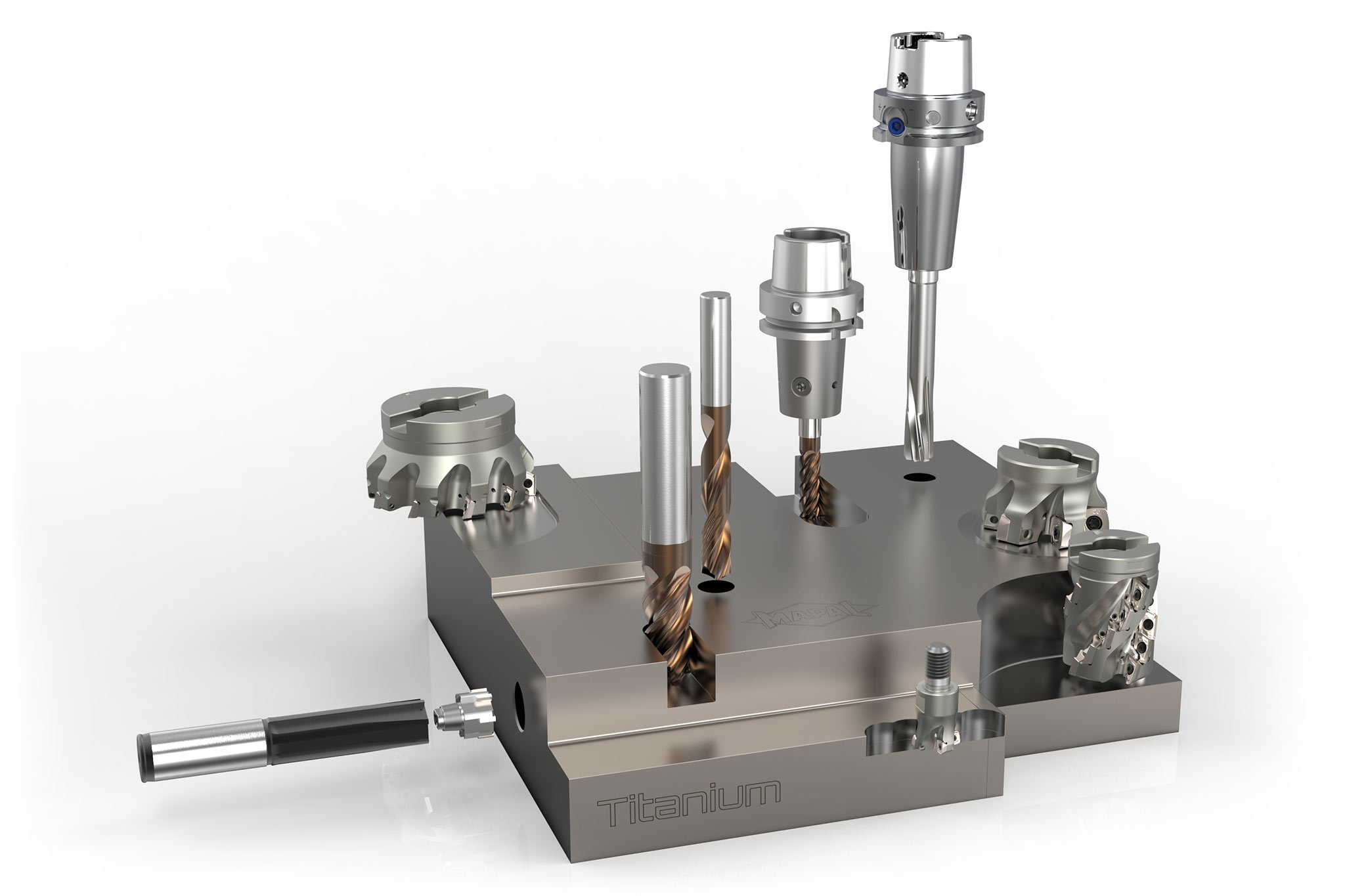

Soluciones de mecanizado para titanio

Los materiales de alta resistencia y al mismo tiempo ligeros son de una importancia central en la industria de la aviación. Con novedosas combinaciones de materiales se puede seguir reduciendo el peso, al mismo tiempo que se aumenta la rigidez y la resistencia a la corrosión, así como lograr una simplificación del montaje mediante una construcción integradora. Mientras que los componentes estructurales de aluminio, titanio o aceros de alta resistencia se mecanizan en centros de mecanizado o máquinas de portal, en el montaje final el mecanizado se realiza con máquinas manuales, unidades de avance de taladrado o robots.

Programa de herramientas para el mecanizado de titanio

Fresado con insertos de corte fijos

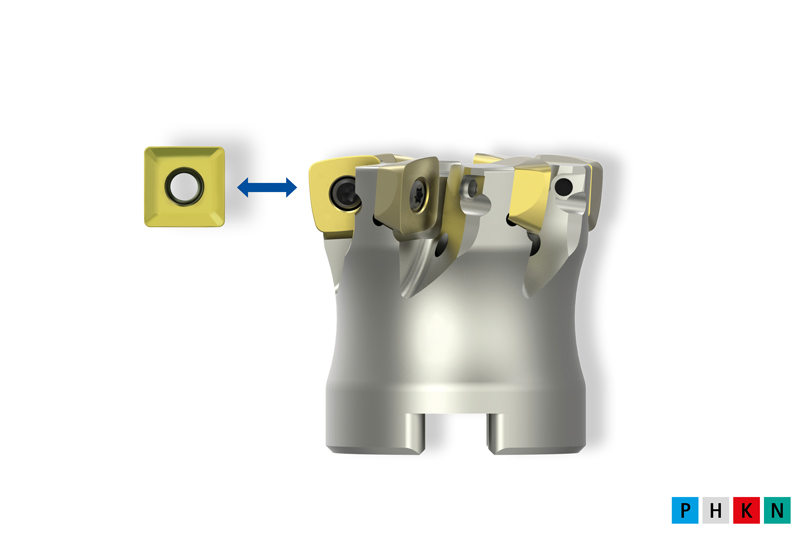

Fresas con insertos intercambiables

Taladrado en macizo

リーマ加工およびファインボーリング加工

ボーリング

クランプ

チタン加工のエキスパート