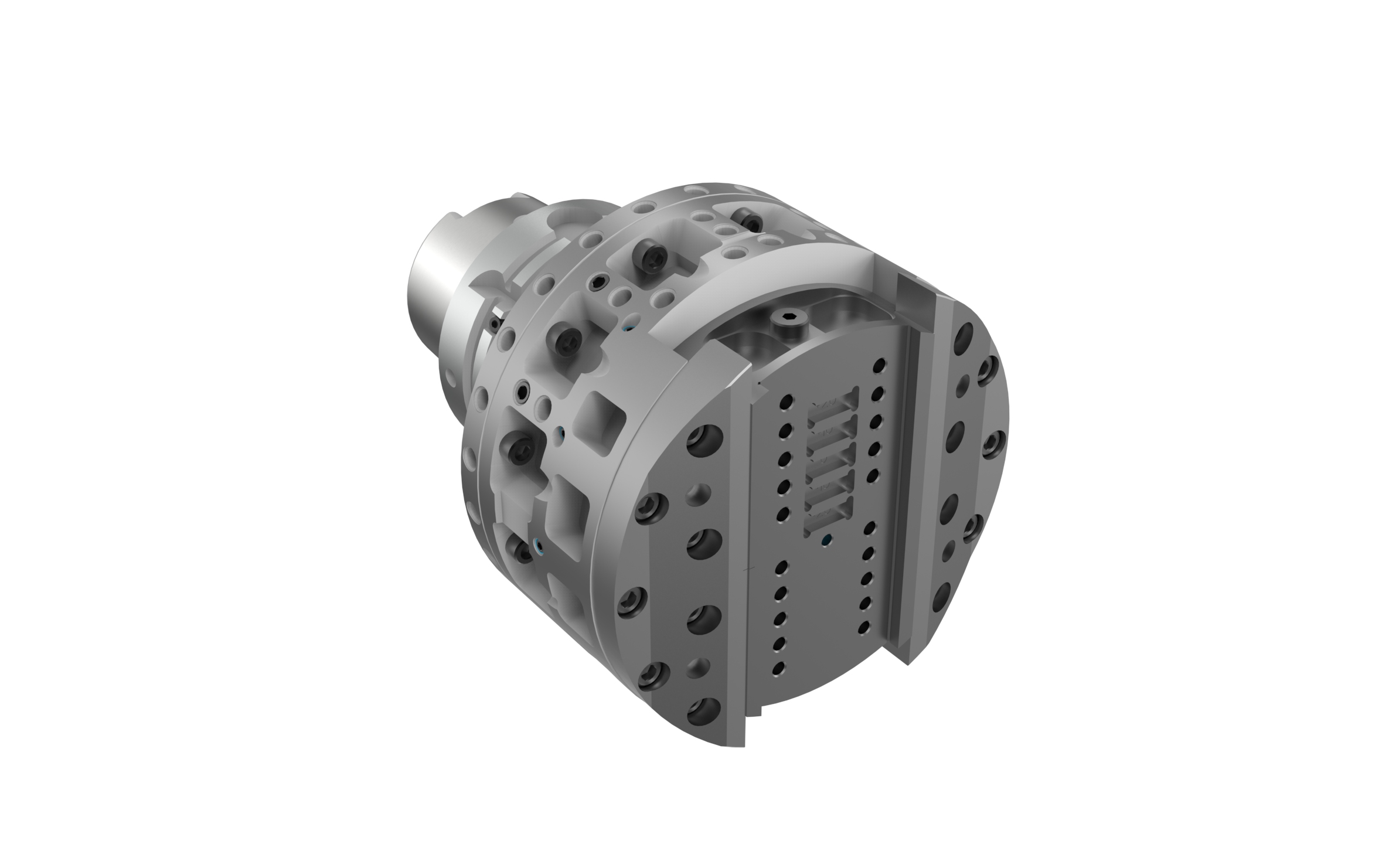

Shut-off valve housing

Shut-off valve housing EN-GJL-250

Initial situation at the customer

/Absperrventil.607-2-.jpg)

- Large variety of components (DN 65 – DN 300)

- Flexible machining necessary on the machining centre

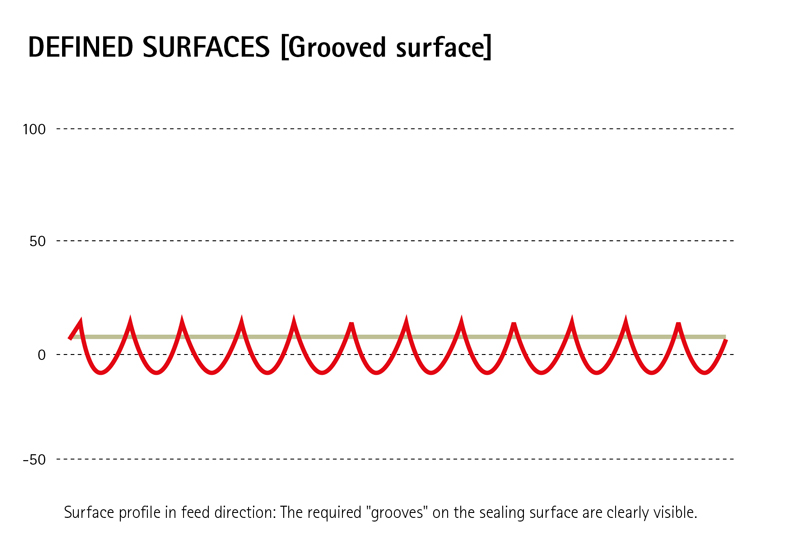

- Challenging machining of parts to achieve defined surfaces

Special features of this solution

- High feed rates possible; defined roughness depth Ra 12.5 necessitates minimum required feed rates of fz = 0.8 mm

- Large radial stroke and modular tool connection enable a small number of tools to be used for all parts

- Automatic tool change

- Tool configuration does not affect machining times thanks to replacement tools

- The flexible process allows preconfiguration to be done on a setting fixture

- Indexable insert technology for low cutting material costs

Tool highlights

- Automatic tool change for flexible tool deployment

- Mounting tools can be offset in five steps to cover a wide range of diameters

- Optimum coolant supply centrally via the mounting tool directly onto the cutting edge

Advantages

- Large variety of parts handled by a single tool system

- Machining of the flange surfaces and seat rings possible in a single clamping setup

- No clamping errors and maximum productivity

- Actuating technology enables burr-free contour transitions and short cycle times as well as the achievement of defined surfaces

- In case of tool wear, tolerances and quality can be corrected flexibly