Screw vacuum pump housing

Pump housing EN-GJL-250

Initial situation at the customer

- Bottlenecks in project planning and process design due to large increases in lot sizes and a high degree of variation of parts

- Massive problems due to fluctuations in casting quality and therefore reduced process reliability in the inventory process

- Lack of qualified personnel for process supervision during series production

Special features of this solution

- Regulation of casting fluctuations through precisely tuned progressive die

- Optimal guiding and avoidance of vibrations during machining with difficult length/diameter ratios

- Low cutting material costs thanks to insert solutions

- Short cycle time and therefore maximum productivity thanks to multi-blade solutions

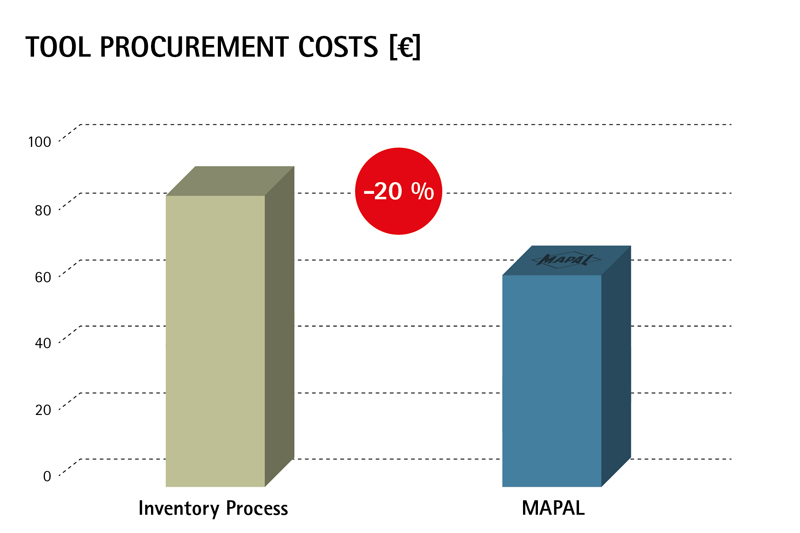

- Cost savings through multiple usage of tools for parts families (20% savings)

Suction chamber bore

Advantages

- The digitalised MAPAL tool management service enables tools and processes to be managed smoothly and optimised continuously

- Efficient end-to-end planning and engineering services from a single source – the Technology Expert Team

- Multiple usage of existing MAPAL solutions, adapted to new projects and parts

- Reliable overall process for pump chamber bores

- Qualification of specialist personnel through training as well as support on site regarding the optimal use of the tool solution