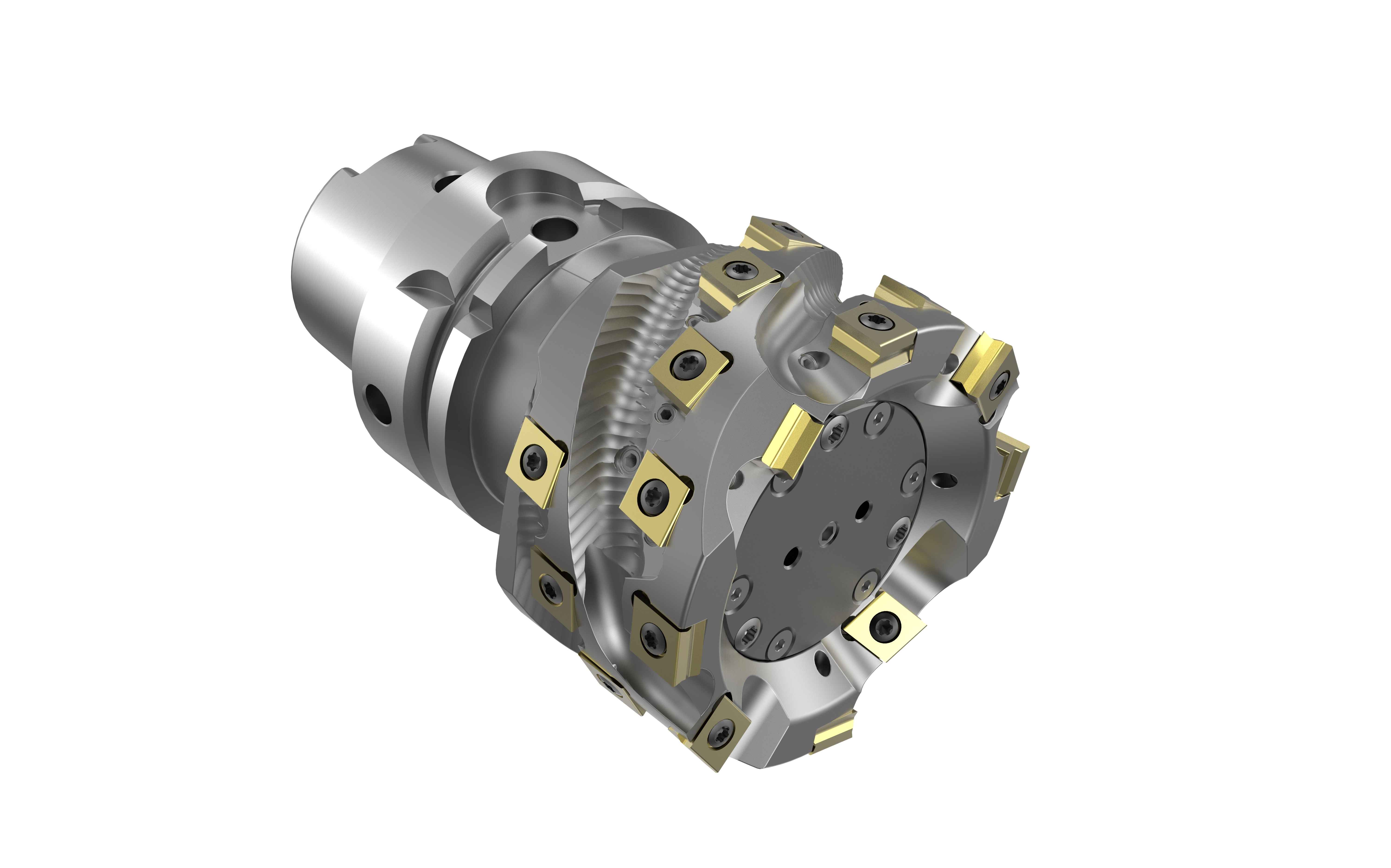

Bomba de vacío de garra

Carcasa de la bomba EN-GJL-250 |

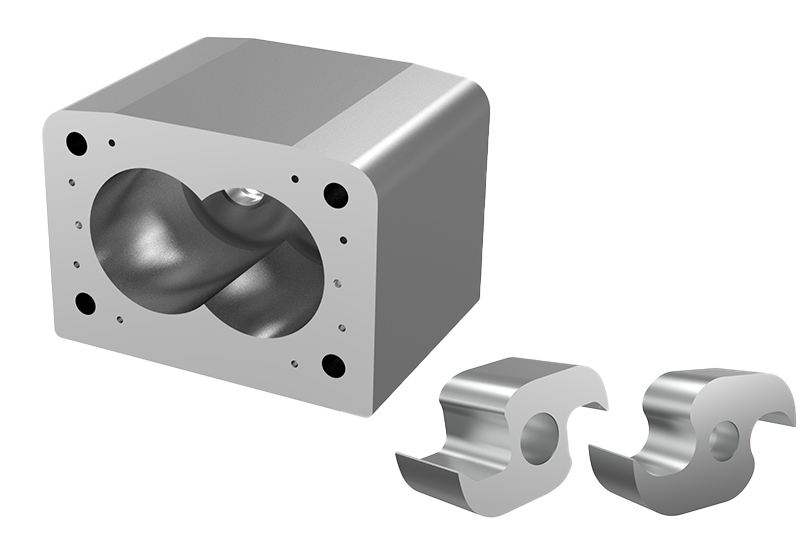

Garras de 1.4021 (X20Cr13)

Garras de 1.4021 (X20Cr13)

Situación inicial del cliente

- Altos costos de las herramientas por soluciones de mecanizado poco flexibles en el proceso de producción en serie

- Enorme presión de costos por un importante componente de mecanizado al producir las garras

Particularidades de esta solución

- Menores costos de materiales de corte con soluciones de insertos de corte intercambiables

- Herramientas combinadas y tecnología de perforación de precisión de MAPAL, para un óptimo diseño de procesos y para mantener la forma y las tolerancias de posición críticas sin herramientas adicionales

- El amplio programa estándar de fresas de mango cilíndrico para metal duro macizo ofrece una alta rentabilidad para el fresado trocoidal en materiales difíciles

- Las plaquitas de corte intercambiables suave tangenciales requieren menos potencia de husillo

Carcasa de bomba

Garras

Vorteile

- Hohe Flexibilität bei großer Varianz - sechs verschiedene Bauteilgrößen mit nur einem Werkzeugkonzept abbildbar

- Reduzierte Werkzeugkosten

- Bearbeitungsprozess der Klauen signifikant reduziert

- Optimaler, wirtschaftlicher Gesamtprozess durch MAPAL