09.03.2020

The c-Com wear detection app - a technical advisor in your pocket

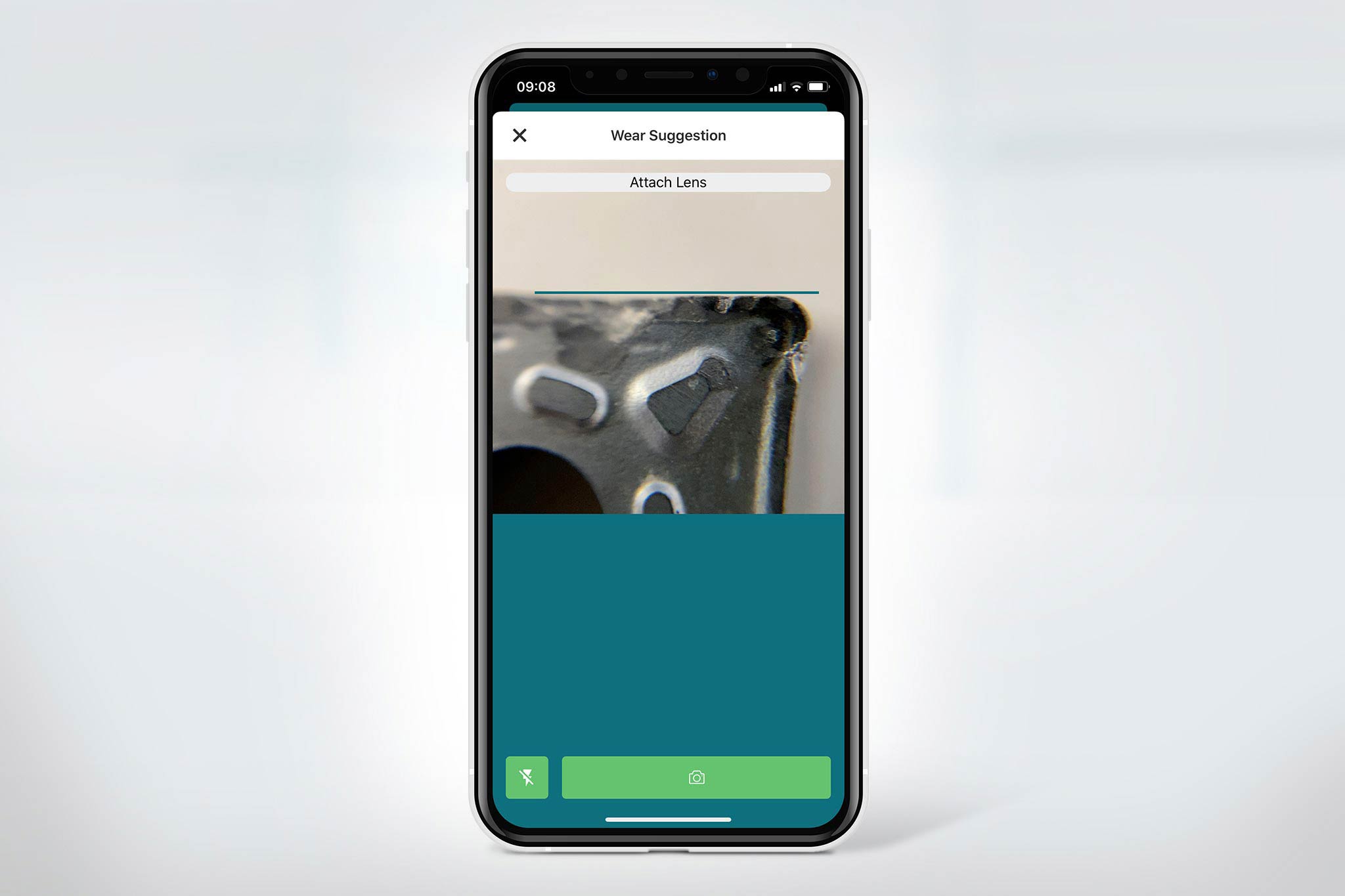

The app detects wear and offers recommendations for action

Many factors need to work in concert to create a smooth, reliable machining process with optimal results. If the process results in poor output or even rejects, there may be multiple reasons for it. If worn blades are the cause, the following questions present themselves: What kind of wear are you dealing with? Why is this wear occurring and how can it be prevented in the future?

The application is based on machine learning, a sub-category of artificial intelligence. This means that the application uses datasets to learn. Together with tool specialists at MAPAL, c-Com has compiled and categorized hundreds of images. Effectively, the algorithm was trained by being shown what different types of wear look like, allowing it to assess whether or not a blade is in good order.

As a result, the application can identify different types of wear, including clearance surface wear, crater wear or a built-up edge. Based on this, the app then provides appropriate suggestions – such as reducing the feed, increasing the spindle speed or using a different kind of coating. At present, the advice and suggestions for how to proceed are still static. However, the c-Com team is working hard on the beta version of the app to enable it to use the application data for each tool to provide specific individual suggestions on what action to take. Put simply, it’s a technical advisor you can keep in your pocket – with numerous potential extensions aimed at making users’ lives easier.