Technologiepartner und Komplettanbieter im Werkzeug- und Formenbau

MAPAL liefert neben Werkzeugen und Spannfuttern komplette Prozesse und den Weg in die digitale Fertigung.

Werkzeug- und Formenbauer erwarten von ihrem Werkzeugpartner hohe Prozess- und Produktkompetenz. Denn die Lebensdauer der zu erzeugenden Formen und die Präzision der Formteile sind für die Wettbewerbsfähigkeit bei der Herstellung der Endprodukte enorm wichtig. Von den Werkzeugen werden deshalb höchste Präzision, lange Standzeiten und vor allem Prozesssicherheit gefordert.

Genau diese Aspekte sind es, die MAPAL in Branchen wie der Automobilindustrie, dem Maschinenbau oder der Luftfahrtindustrie erfolgreich machen. So ist es nur folgerichtig, auch im Werkzeug- und Formenbau effiziente und wirtschaftliche Lösungen für den kompletten Zerspanungsprozess anzubieten.

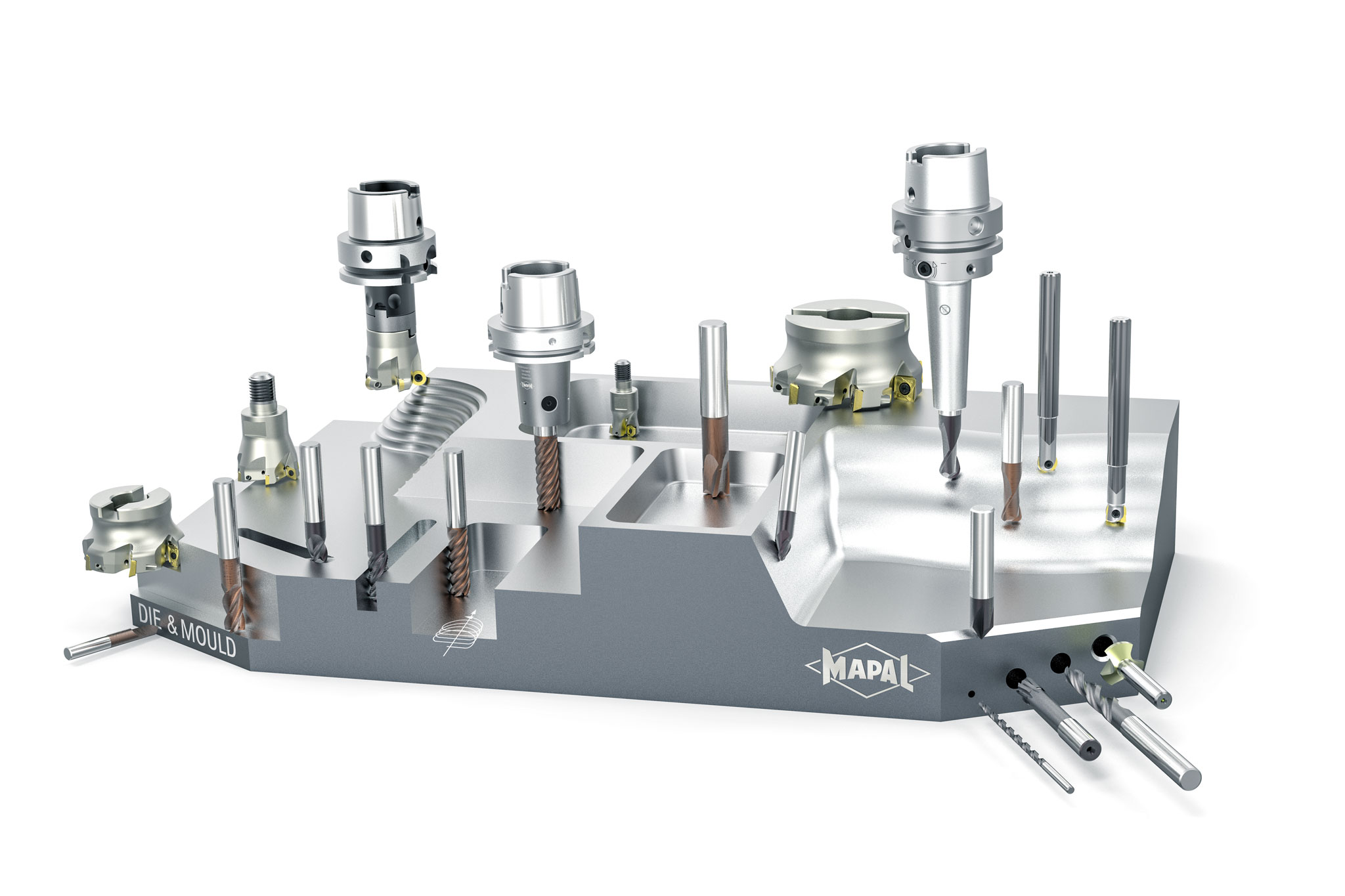

Das Programm für den Werkzeug- und Formenbau bildet einen Querschnitt durch das Werkzeugportfolio von MAPAL, vom Fräsen mit festen und wechselbaren Schneiden, Bohren über das Senken bis hin zum Reiben. Rund 6.500 Artikel, abgestimmt auf die zum Einsatz kommenden Werkstoffe, wie Stahl, gehärteter Stahl, Gusseisen, Aluminium und Kupfer sowie Graphit, umfasst das Portfolio. Zahlreiche Highlights, wie beispielsweise Fräser mit Hochvorschubgeometrie, gehören dazu.

Sowohl die VHM-Ausführung der OptiMill-Baureihen als auch die Varianten mit wechselbaren Schneiden ermöglichen eine Bearbeitung mit hohen Abtragsraten und sind flexibel einsetzbar. Darüber hinaus zählen zu den Highlights auch die Kreisradiusfräser OptiMill-3D-CS mit ihrem großen Wirkradius oder die Bohrreibbahle MEGA-Drill-Reamer, die zwei Arbeitsgänge in einem kombiniert und vorwiegend bei Passstift und Auswerferbohrungen zum Einsatz kommt.

Angesichts der hohen Spezialisierung im Marktsegment Werkzeug- und Formenbau sowie der stark zunehmenden Nachfrage nach Technologie- und Managementlösungen, stehen bei der Auswahl des passenden Zerspanungspartners natürlich nicht mehr Werkzeuglösungen allein im Vordergrund. Bearbeitungsstrategien, Werkzeugmaschinen, Werkstückspannsysteme, CAD-CAM-Systeme sowie Lösungen zum Toolmanagement sind Teil des Zerspanprozesses und entscheiden über eine effiziente und wirtschaftliche Fertigung.