19.10.2023

Faster thanks to structure and agility

As Chief Technology Officer, Jacek Kruszynski has been responsible for product and market segment management as well as research and development since October 2021. The editorial team at IMPULSE spoke to the Chief Technology Officer about structures, development priorities and plans in the field of digitalisation.

Mr Kruszynski, you have restructured MAPAL’s Product and Market Segment Management and put it on a new footing. How has the new structure been received in the market? Are the projected benefits apparent yet?

An important goal was to become significantly faster, for example when configuring tools or whole machining processes. How did you achieve this goal?

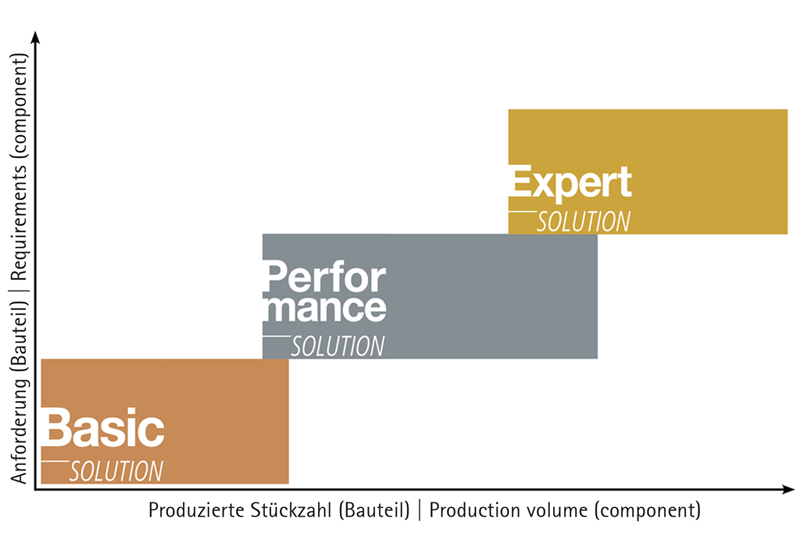

The requirements of individual markets and regions, and of individual customers in a region, vary considerably in terms of product volumes and quality requirements. The costs of a machining solution also play a role. We based our Basic Performance Expert classification on this requirements matrix, which we use to envisage application- and customer-specific machining solutions to a certain degree. With this approach, we meet our customers where they are in terms of production volume and quality requirements.

Incidentally, this classification has been in place for years for catalogue products. Carrying it over to components reflects our expertise in terms of customer-specific solutions. A basic solution is, put simply, designed for small series, for prototype production. However, this certainly doesn’t mean that the machining solution is “simple”. Of course, many standard tools are used here with the associated cost benefits. A highly complex custom tool used in the expert solution for mass production with high quality standards would never pay off in such a case. The classification provides a basic framework that our technical advisors can use to address specific needs.

MAPAL presented the Basic Performance Expert solutions on the stator housing for electric motors last year. Does this portfolio of sample solutions also exist for other parts?

Ja, selbstverständlich. Diese Herangehensweise wenden wir für viele Fokuskomponenten an, bei denen wir entsprechende Qualitätsanforderungen, Produktionsmengen und Kostenvorgaben sehen. In der Fluidtechnik zum Beispiel für Ventilgehäuse oder Steuerblöcke.

Welche Vorteile bietet diese Klassifizierung für den Kunden? Und für MAPAL?

MAPAL war immer dafür bekannt, für den einzelnen Kunden „das letzte µm“ herauszuholen. Ist diese Herangehensweise damit überholt?

Wie entwickeln sich die Fokusmärkte von MAPAL?

Wo liegen aktuell die Entwicklungsschwerpunkte?

Neben dem Fokus auf Prozesslösungen für konkrete Bauteile hat MAPAL in den vergangenen Jahren konsequent sein Standardportfolio auf- und ausgebaut.

Nun gibt es einen Online-Shop mit einem lagerhaltigen Programm. Warum war dieser Schritt unerlässlich und was ist Ihr Ziel im Bereich Standard?

Standardwerkzeuge machen Hersteller vermeintlich direkt vergleichbar. Wie punktet MAPAL trotzdem?

Neben kundenspezifischen und Standardwerkzeugen sind die digitalen, die datenbasierten Werkzeuge und Lösungen inzwischen eine unerlässliche dritte Dimension, die jeder Werkzeughersteller haben muss. Wie geht MAPAL mit dieser Herausforderung um?

Natürlich arbeiten wir intensiv an digitalen Lösungen für unsere Kunden. Daneben treiben wir durch Digitalisierung und Automation die Effizienzsteigerung in der eigenen Produktion voran. Die Bereitstellung einer digitalen Plattform zur Entdeckung einer Marke und ihrer Produkte ist eine Anforderung heutiger Märkte. Das trifft in unserer Branche ebenso zu und hat große Auswirkungen. Digitale Lösungen gibt es inzwischen viele. Meiner Meinung nach sind jedoch noch kaum „Easy-to-use“ Solutions auf dem Markt. Selbstverständlich, es gibt Online-Shops und Auswahlguides. MAPAL selbst bietet über c-Com Softwarelösungen für das Toolmanagement an, wobei wir die Logistik und die Umlaufphase monitoren und auch Rückschlüsse ziehen, um die Werkzeuge zu optimieren. Aber bei umfassenden Lösungen gibt es tatsächlich noch sehr viel Luft nach oben. Setzen diese doch voraus, dass Kunden ihre Fertigungseinrichtungen für uns beziehungsweise allgemein Lieferanten ganz öffnen und tiefgreifende Partnerschaften einzugehen bereit sind.

Grundvoraussetzung für alles Digitale ist natürlich die Datenbasis. Die muss stimmen. Alle unsere Produkte müssen „Ready for Digitalisation“ sein. Da spielen verschiedene Formate und Plattformen eine Rolle. Aufgrund der Wichtigkeit dieser Thematik haben wir ganz aktuell die neue Abteilung „Product Automation“ ins Leben gerufen, die sich um alle Belange der Digitalisierung unserer Produkte kümmert und den digitalen Zwilling über die einzelnen Prozesse hinweg strukturiert, erstellt und pflegt. Übrigens konnten wir viele der dafür ausgeschriebenen Stellen intern besetzen. Das freut mich ganz besonders. Wir haben diese Spezialisten an verschiedenen Standorten in unserer Organisation, die noch dazu MAPAL kennen und direkt produktiv arbeiten können. Durch dieses Bündeln von Kapazitäten und Fähigkeiten erhoffe ich mir ganz viele Synergien und eine Beschleunigung in diesem Bereich.

Welche Ziele haben Sie für die nächsten fünf Jahre?

Ich möchte in jedem Fall in den nächsten fünf Jahren unser Ziel erreichen, die Nummer 1 im Bereich New Mobility zu sein, und das mit schnell und zuverlässig gelieferten Lösungen. Die Kundenzufriedenheit messbar weiter zu steigern, ist mir ebenfalls sehr wichtig. Auch möchte ich in fünf Jahren ein digitales Umfeld haben, mit dem unsere technischen Berater und Ingenieure noch zielgenauer Angebote erstellen können. Über all diesen Zielen steht das Streben danach, unsere Agilität nennenswert zu steigern.

Vielen Dank für das Gespräch.

Kontakt

Kathrin Rehor Public Relations Kathrin.Rehor@mapal.com Tel.: +49 7361 585 3342