Produzione di piccole e medie serie con utensili non registrabili

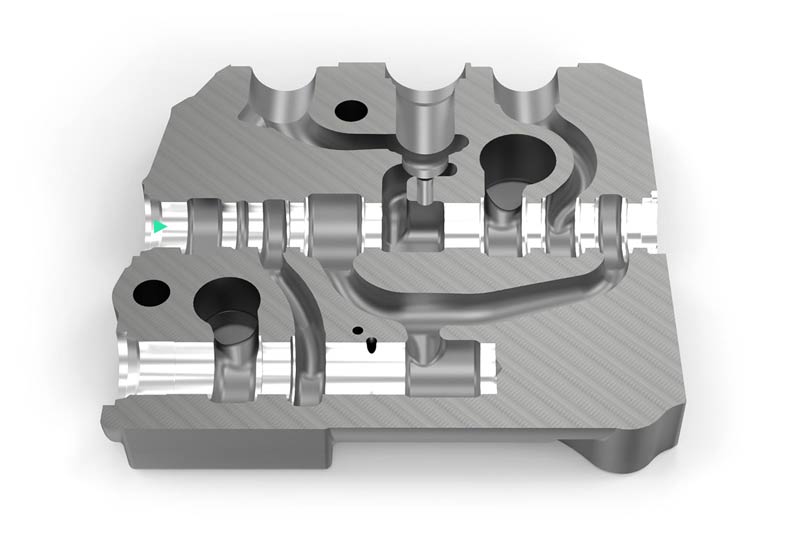

Corpo valvola EN-GJS-400-15 – Foro cursore

Situazione di partenza del cliente

- Ordini individuali, piccole e medie quantità

- Nessuna possibilità di registrazione utensile

- Lead time ridotto richiesto

- Elevati costi orari della macchina

- Disponibilità di un processo di levigatura a espansione stabile

- Progettazione utensile adattata a diverse varianti di componenti

Special features of this solution

- No ring formation in the cavities due to special bore geometry → no costs for removal of rings

- Optimum results in the pre-machining due to a coordinated piloting and boring process → Support of boring tools in the pilot bore = optimum straightness, position

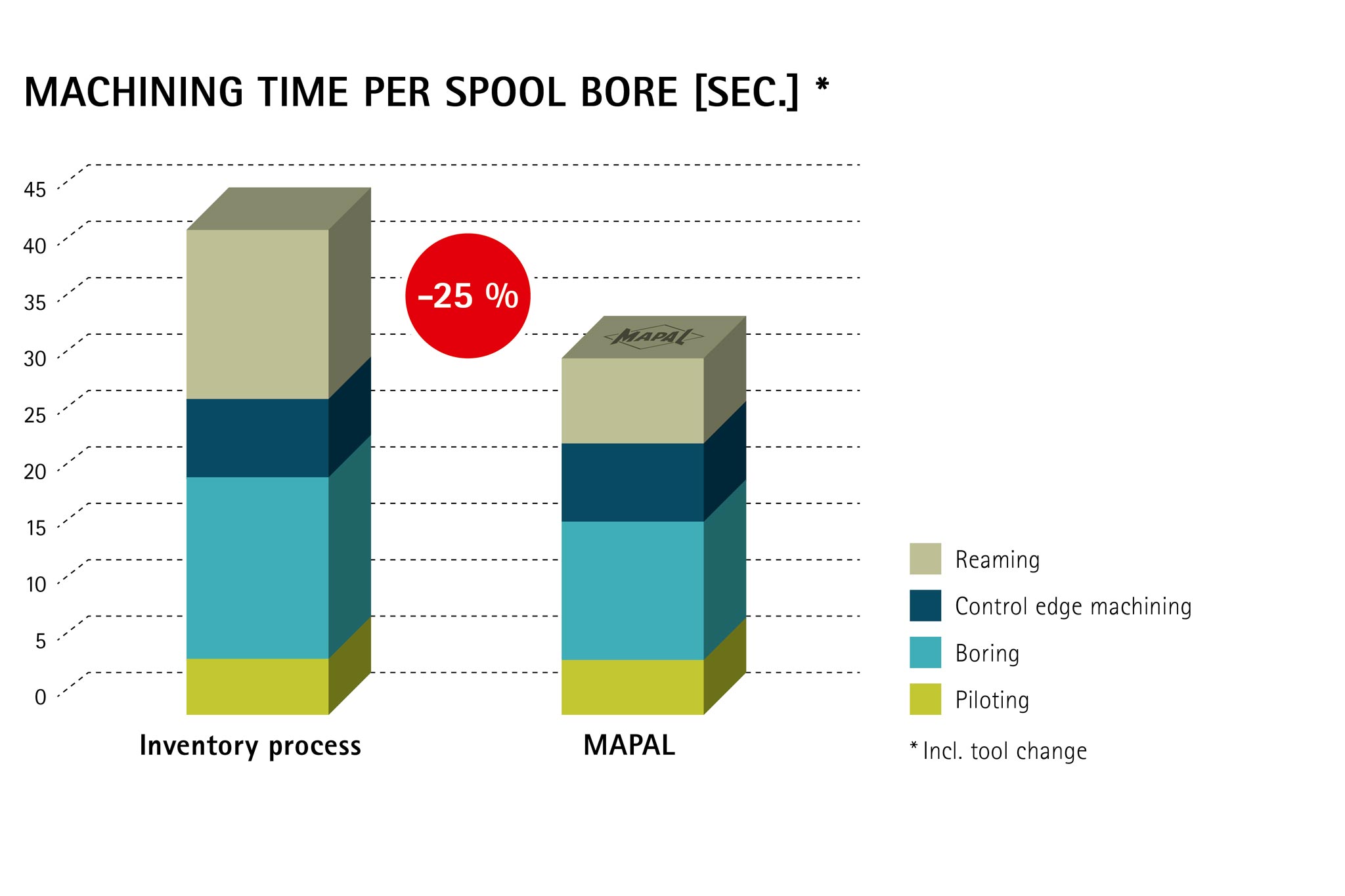

- High productivity with perfect pre-machining quality → High cutting values – machining time is reduced

Spool bore

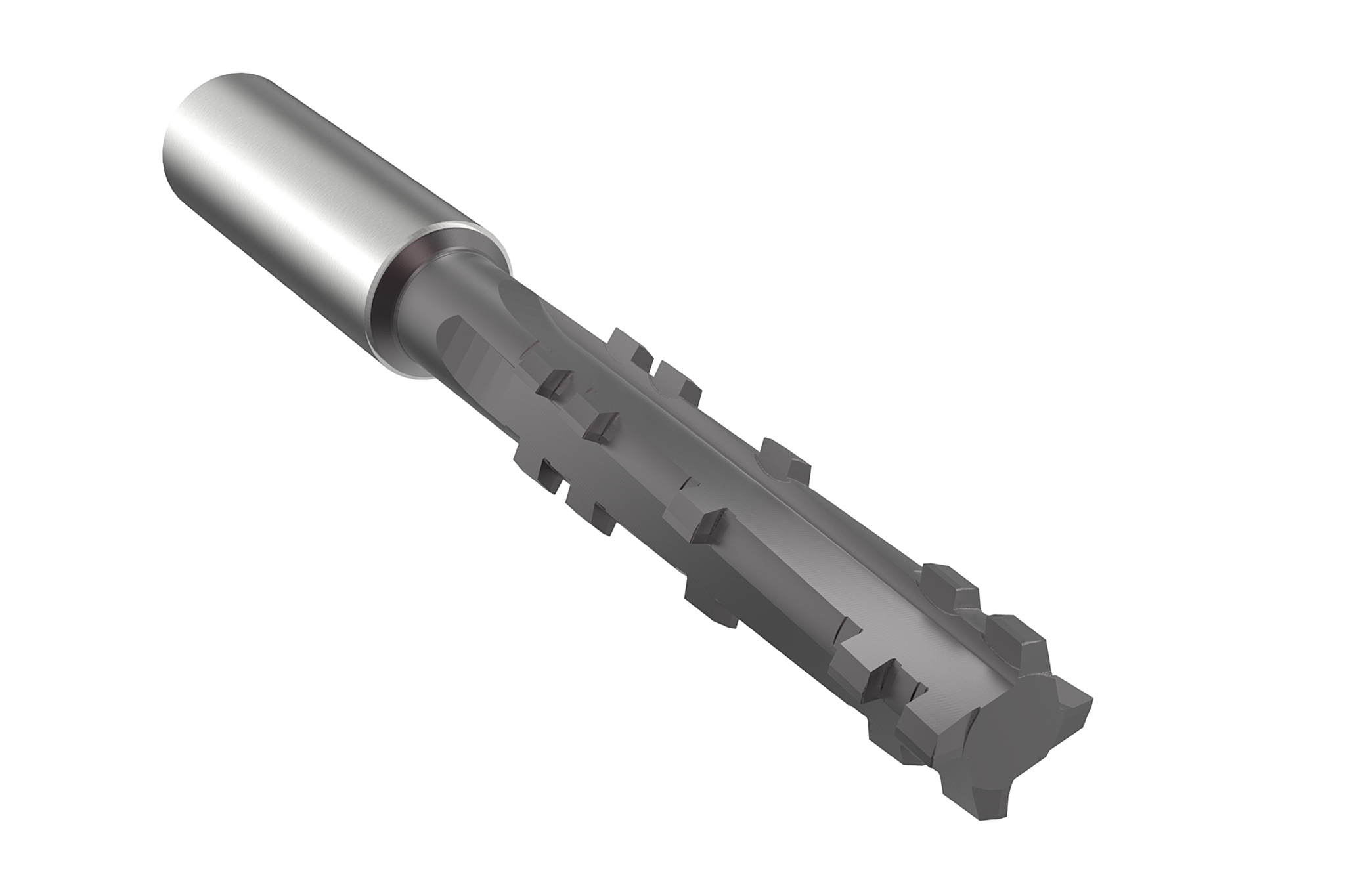

1. Piloting

- Solid carbide-boring tool with six margin lands for perfect roundness and straightness

- Optimum chip flow and extended regrinding options through multicut technology and suitable coolant supply

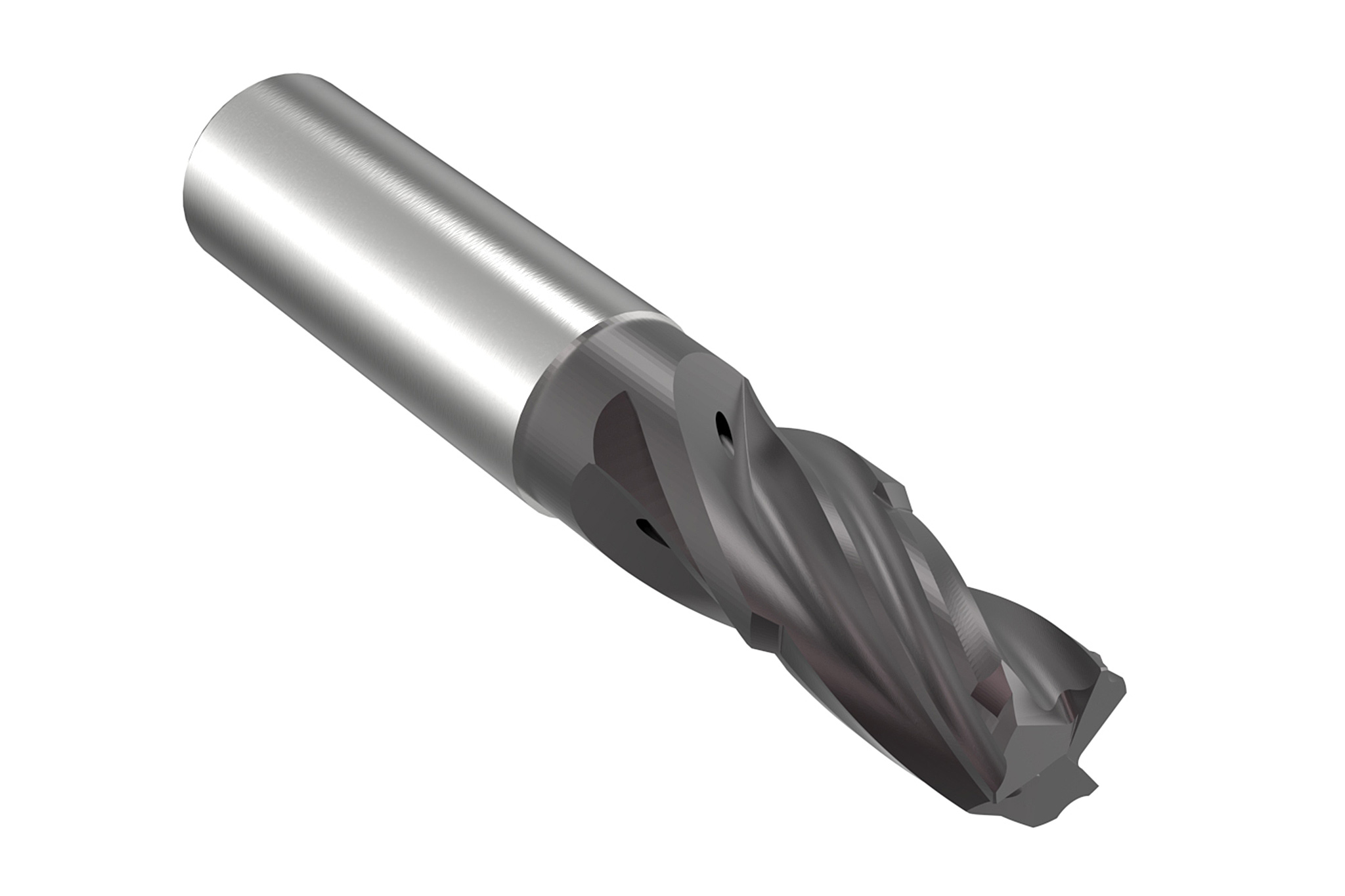

2. Boring

- Solid carbide boring tool with three cutting edges and six margin lands and special lead geometry

- Straight bore, ideal chip flow und guide across the entire bore length

3. Control edge machining

- Significant cycle time savings with special solid carbide circular milling cutter

- Defined control edges without macroscopic flaws

4. Reaming

- Multi-bladed reamer for high cutting data

- Perfect chip control due to left-hand twist and optimum coolant supply

Advantages

- Minimal investment

- Low cycle time

- High availability of the machining centre

- Low production costs

- No tool setting required

- Option for regrinding worldwide