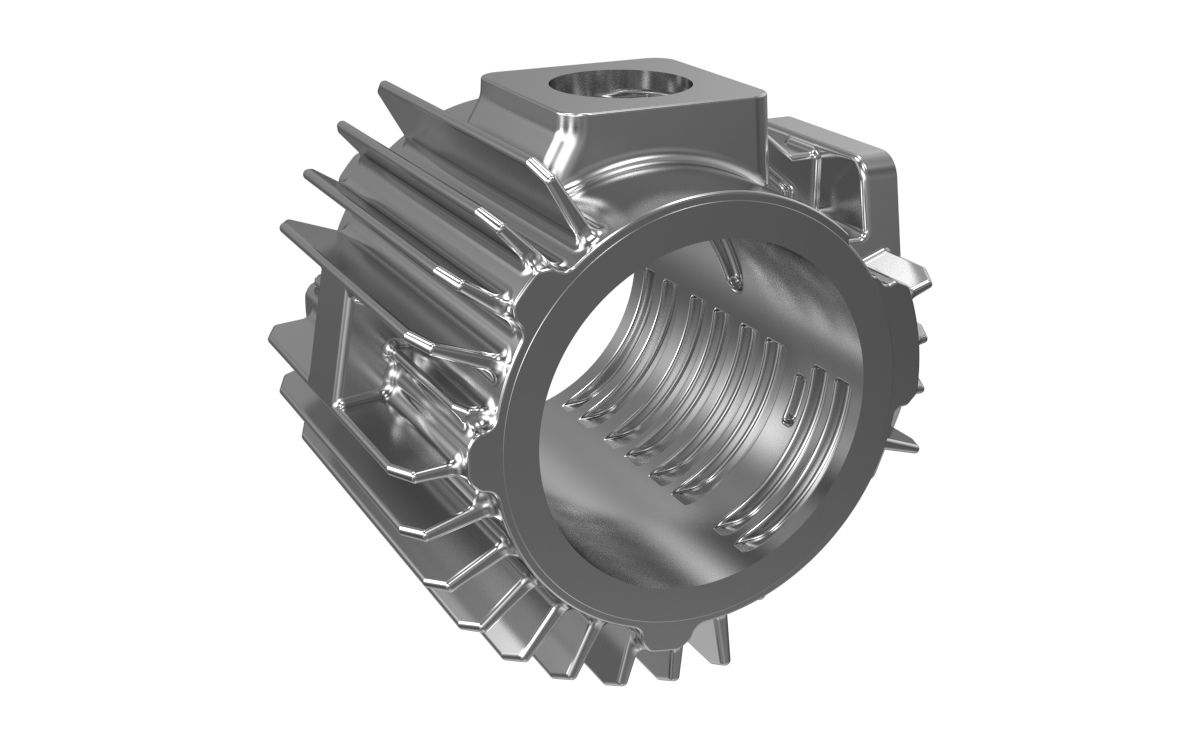

Corpo de bomba de vácuo com palhetas rotativas

Corpo de bomba de EN-GJL-250

Situação inicial no cliente

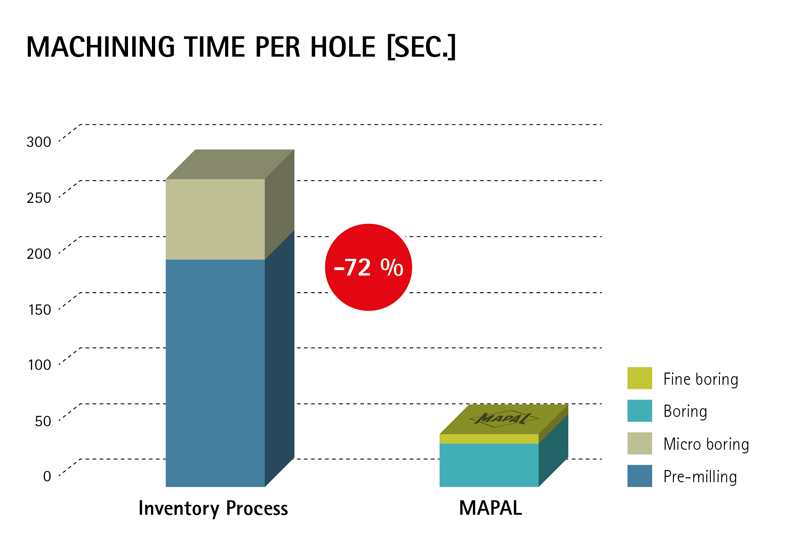

- Demanda significativamente crescente e com isso, exigências paralelas impostas a uma produção otimizada e, ao mesmo tempo, à confiabilidade do processo

- Maior esforço relacionado à tecnologia de produção na usinagem de furos do estator por meio de pré-usinagem e fusos prontos

Características especiais da solução

- Tempos de ciclo curtos e máxima eficiência econômica graças a soluções de ferramentas com diversas arestas de corte

- Manuseio simples no processo em série por meio do sistema EA

- Frequência reduzida do ajuste da ferramenta para acabamento fino devido à alta durabilidade do material de corte da CBN

- Custos baixos com material de corte por meio de soluções com pastilhas intercambiáveis

- Uso múltiplo em diversos materiais de fundição facilmente realizável

Furo do estator

Vantagens

- Otimização do processo em forma de redução do tempo de ciclo com a solução de ferramenta da MAPAL

- Produção significativamente aumentada e usinagem com confiabilidade do processo dos corpos de bombas

- Parte ajustável necessária eliminada devido ao sistema de fusos removido