電気駆動

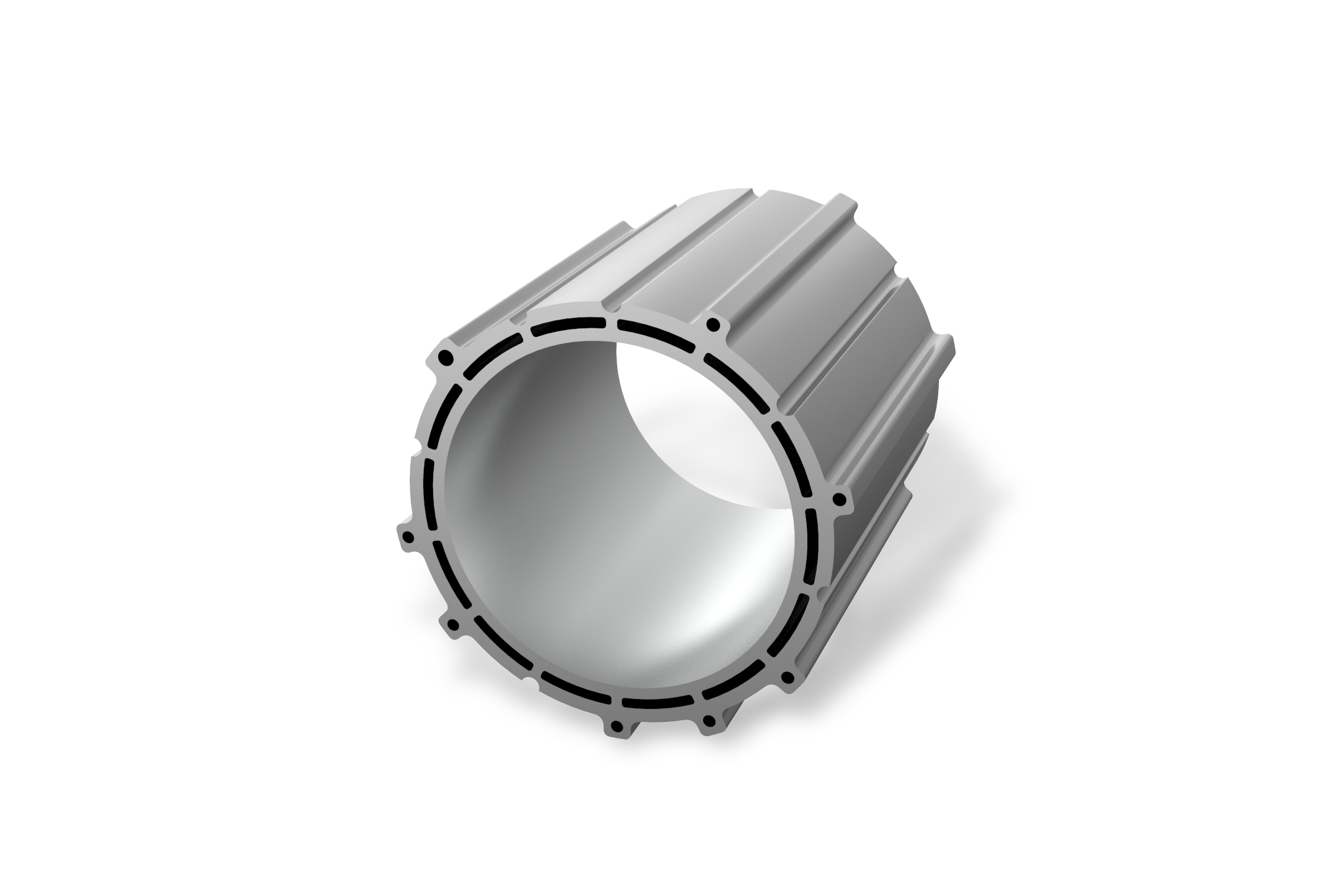

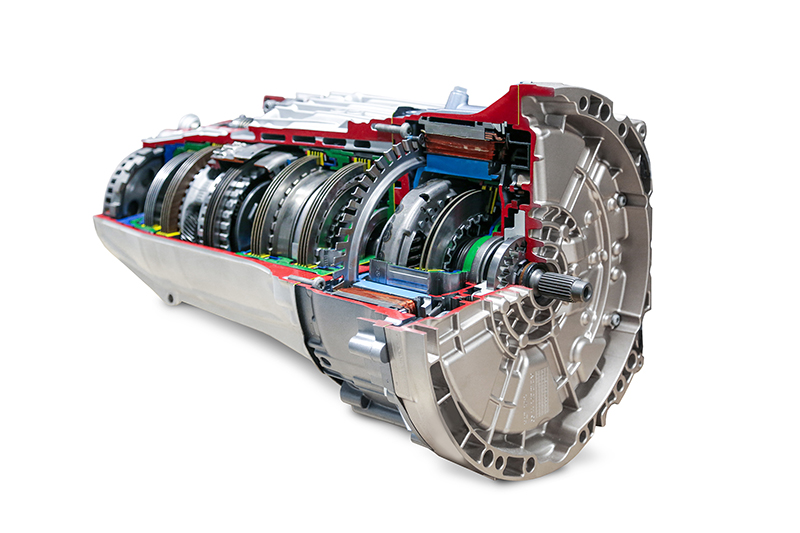

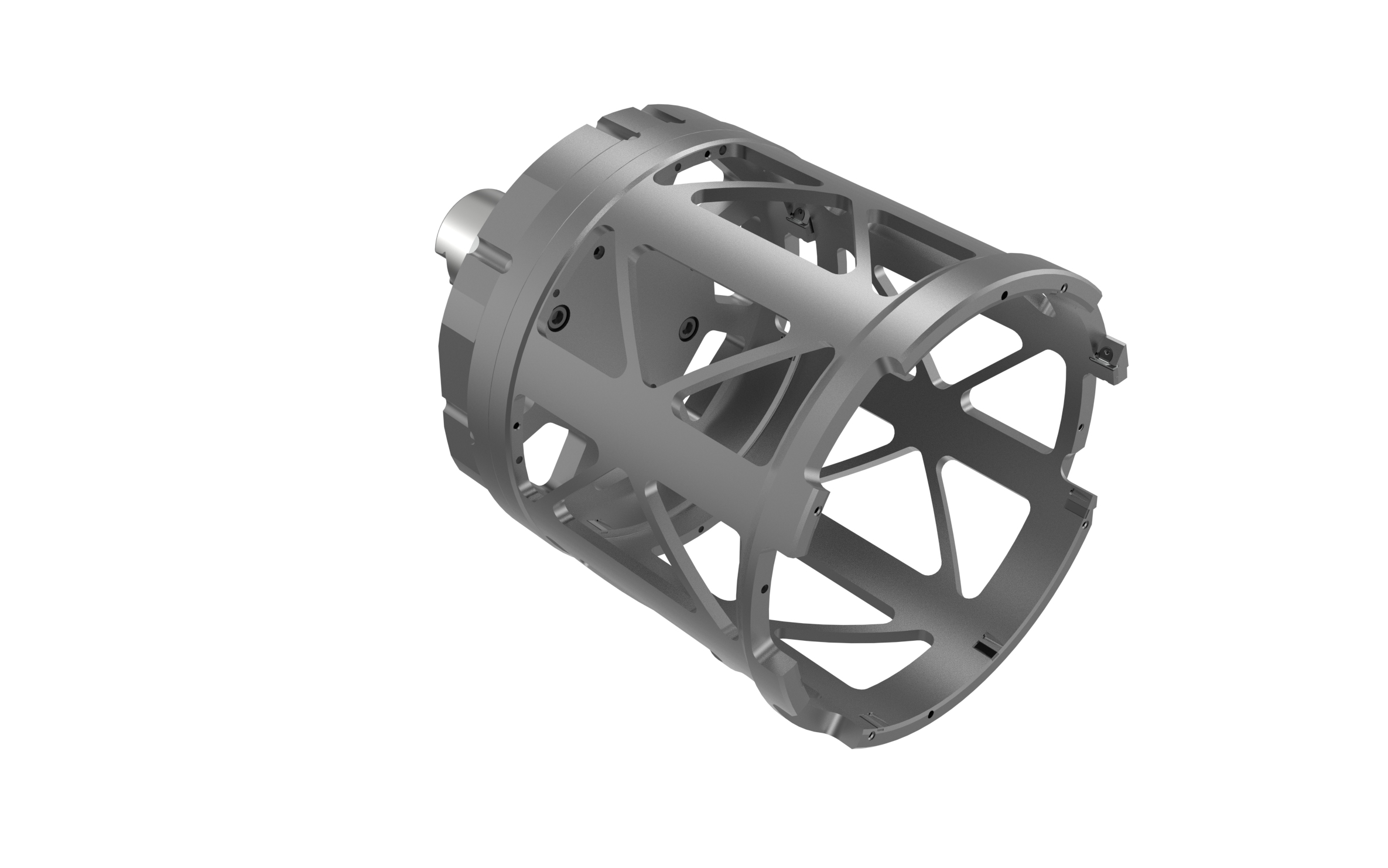

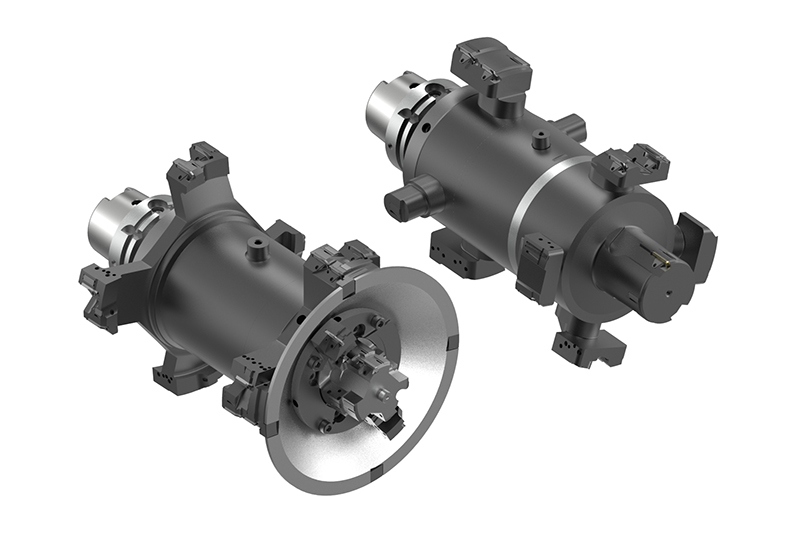

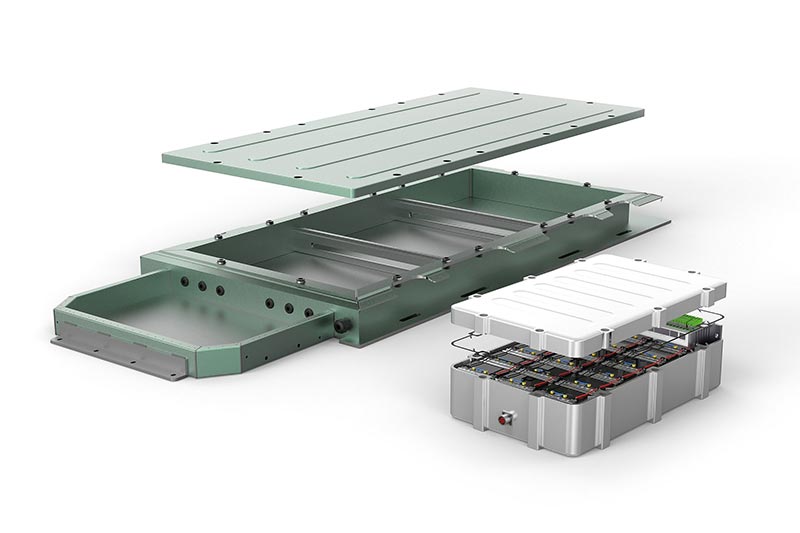

自動車メーカーやサプライヤーは、eモーターの製造パーツに関して新たな課題に直面しています。eモーターハウジングの例を見ると、この問題がいかに大きいかが分かります。ギアボックスハウジングと比較して、精度が電動モーターの効率に決定的な影響を与えるので、はるかに狭い許容範囲内で製造せざるをえません。

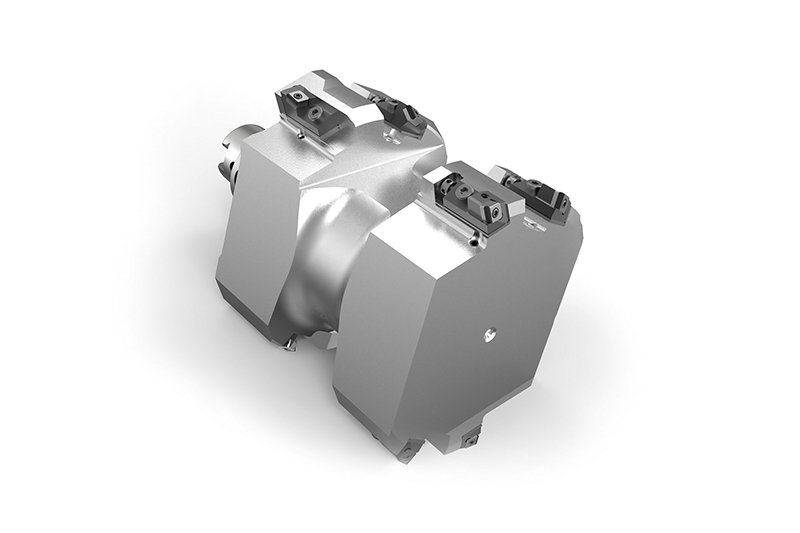

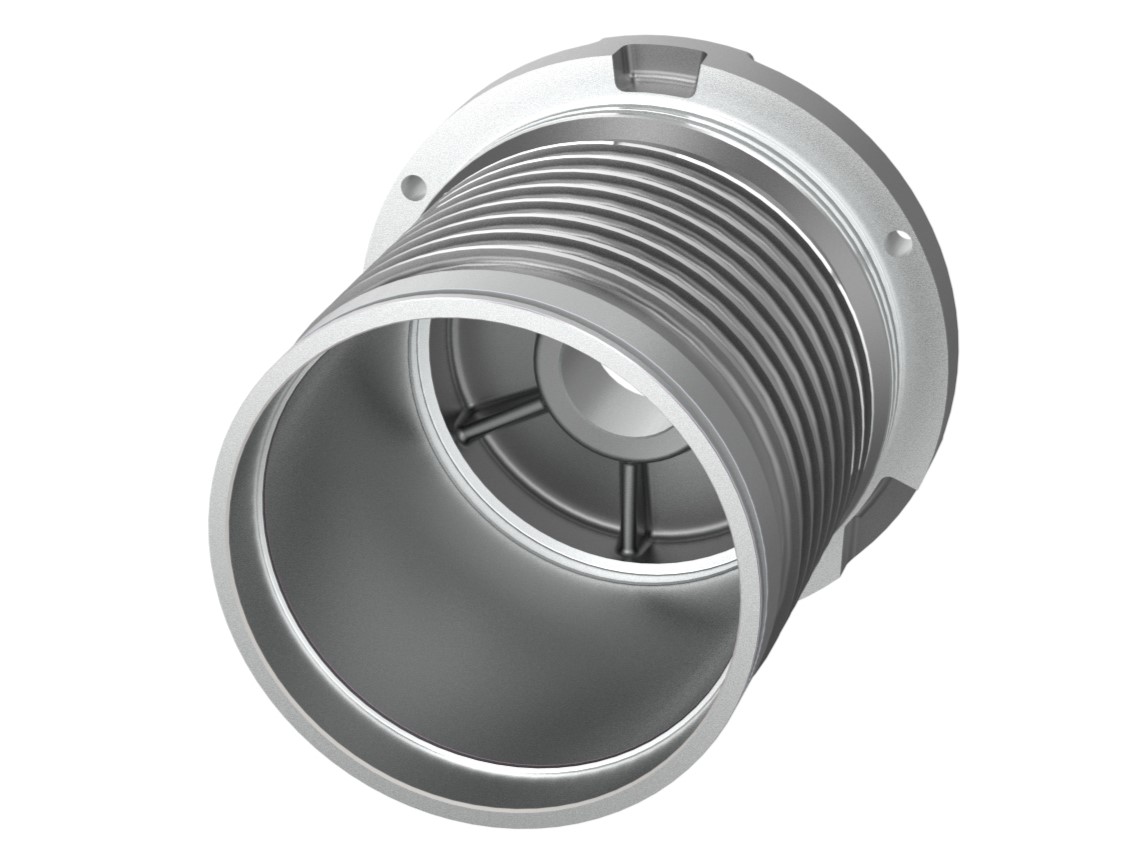

さらにeモーターハウジングは、例えば一体型冷却チャネルのような特殊な設計により、ギアボックスハウジングよりもはるかに薄くなっています。これらのハウジングのいくつかにおいては、さらに鋼材のベアリングレースが押し込まれています。ツール内の特殊な保護シールドにより、加工中にスチールの切り屑がアルミニウムの表面に接触して損傷することはありません。

さまざまなハウジングタイプの機械加工条件&特性

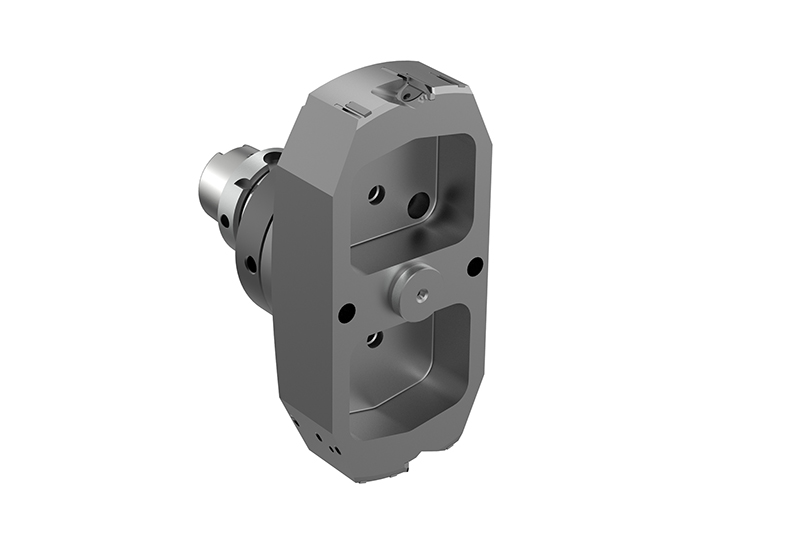

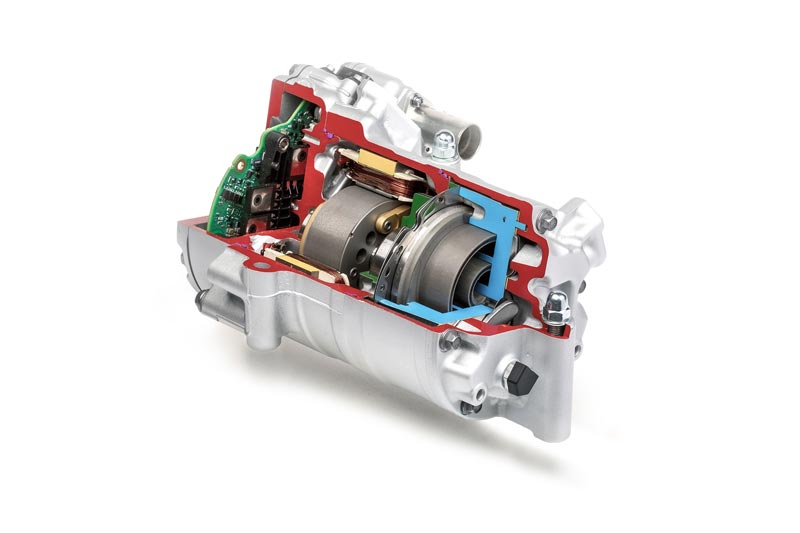

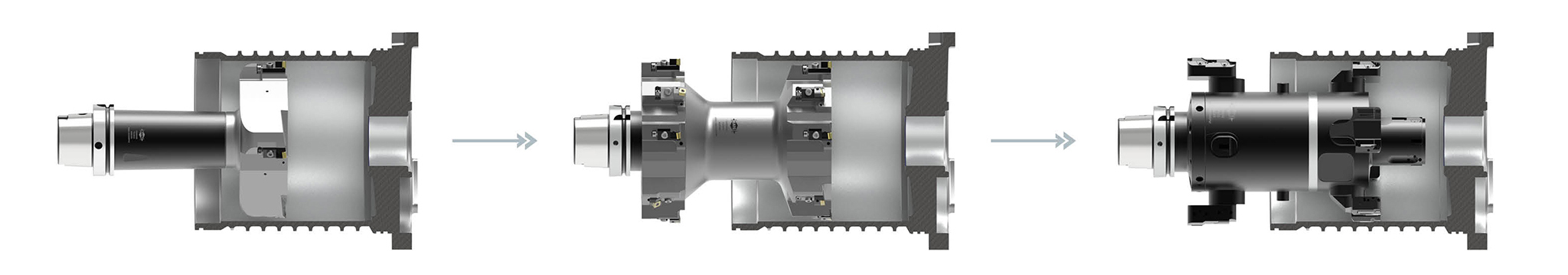

スタータハウジング加工時の基本手順

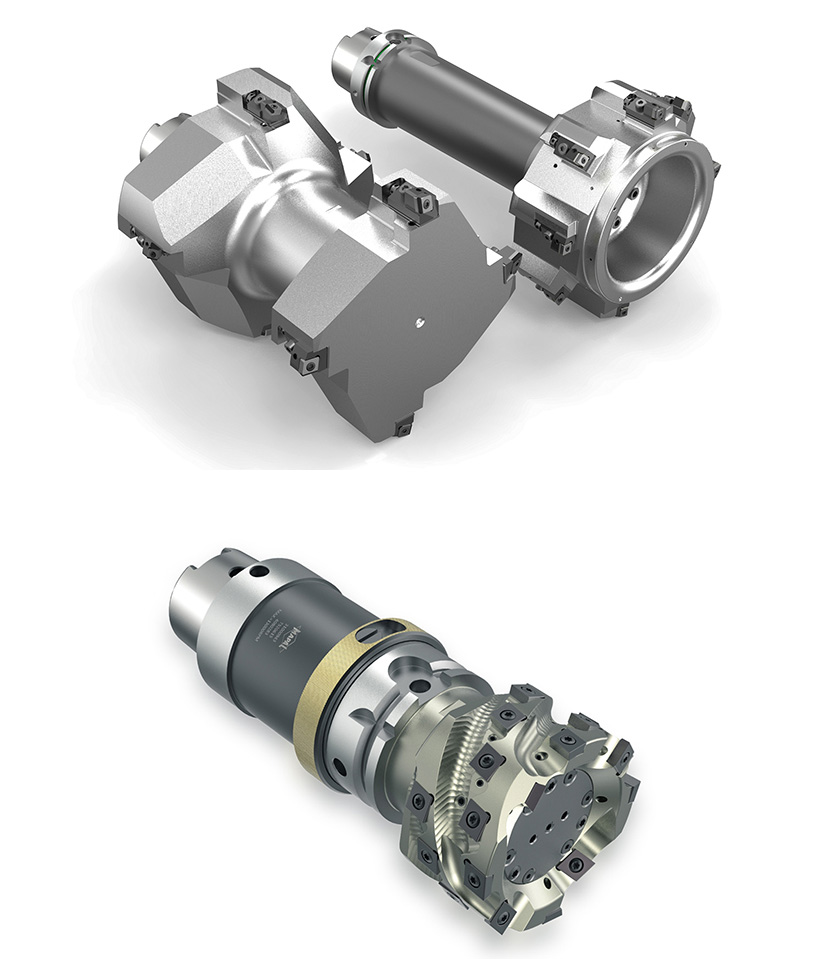

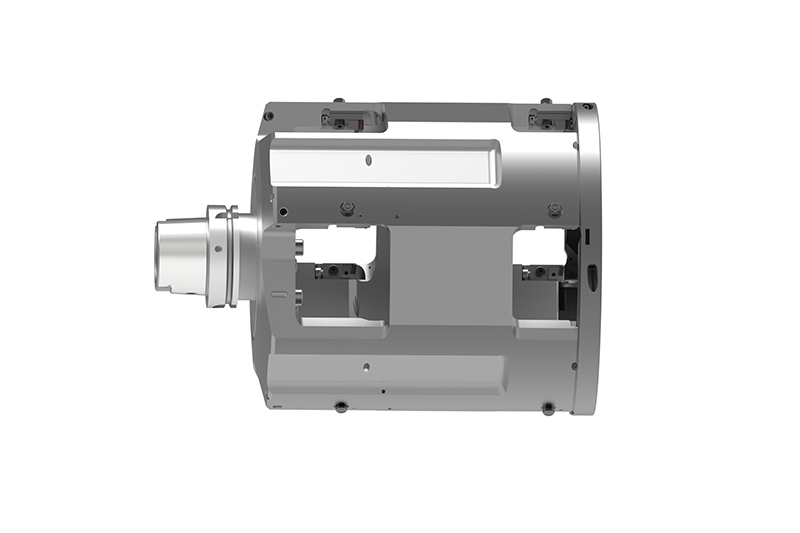

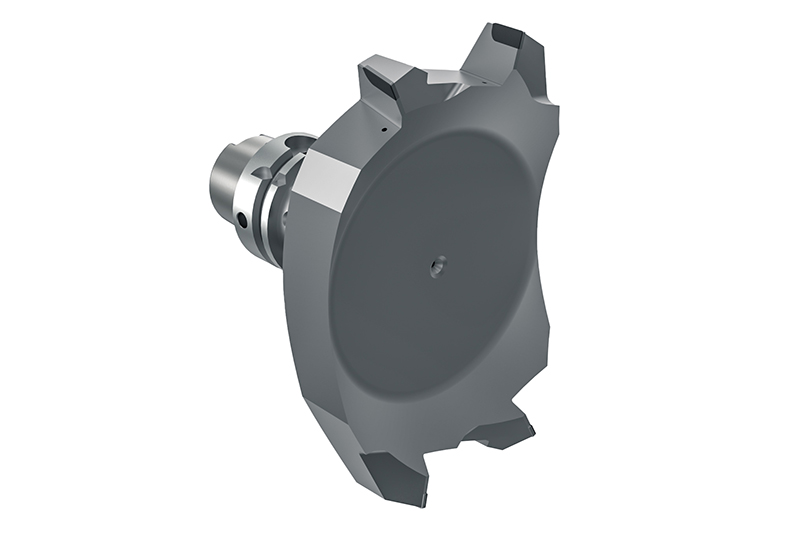

加工プロセスおよび工具は、取り代の状況、機械装置、クランプシステムに応じて個別に設計されます。そうすることで部品に作用する切削力が可能な限り低く保たれます。スタータ穴の加工は、3つのステップに分かれています。前加工、中仕上げ加工および仕上げ加工に分けられます。

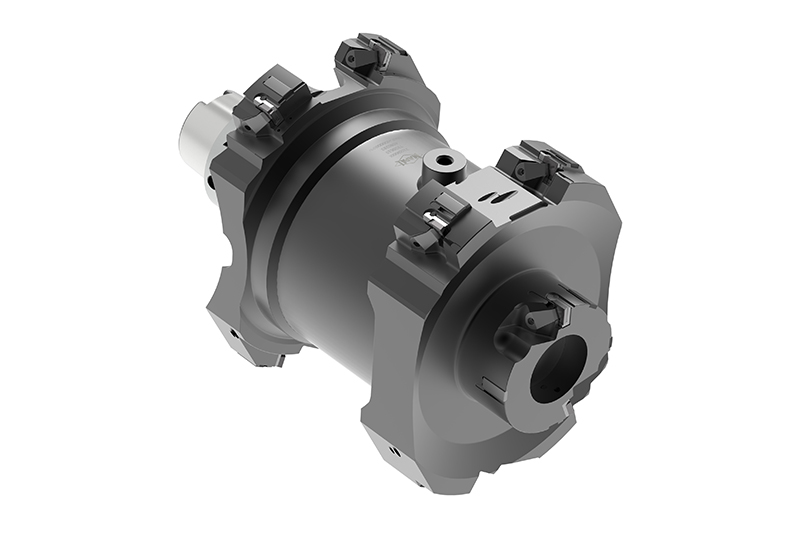

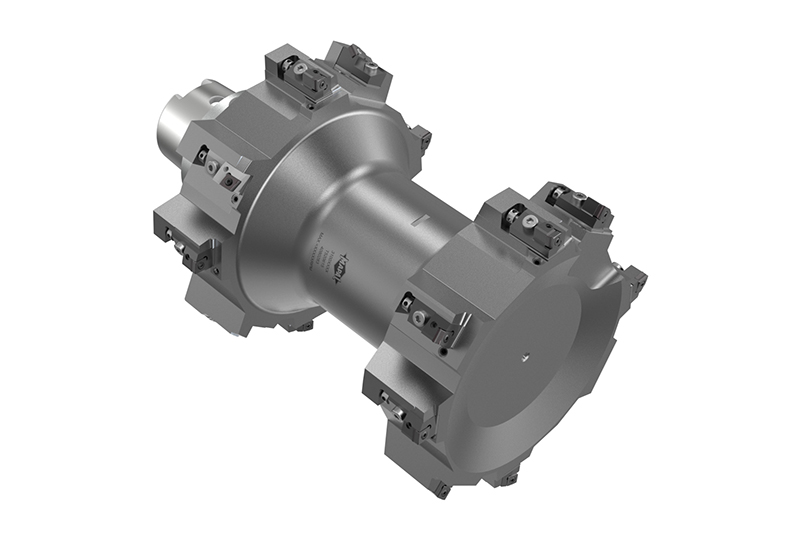

External Machining stator housing

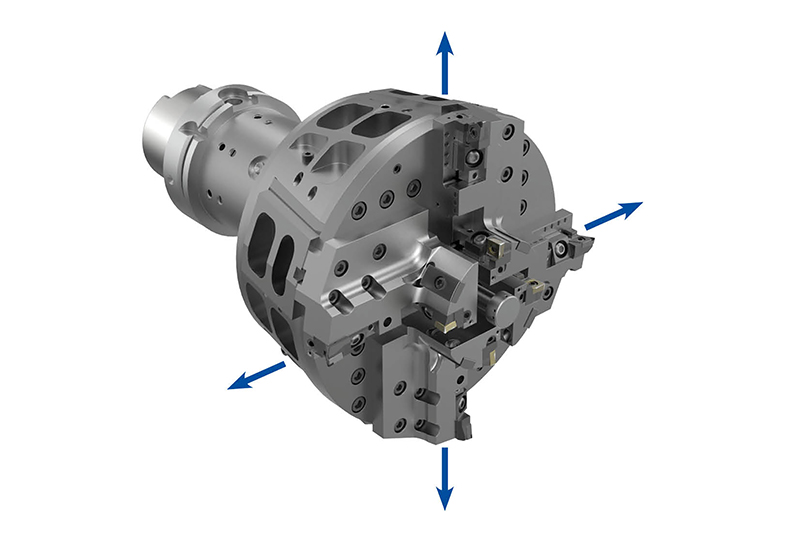

External machining of stator housings for electric motors is a demanding task. These housings, which often come in tubular or pot-shaped designs, are crucial for the efficiency of the electric motor. Several challenges have to be overcome during the process. The thin-walled aluminium housings with integrated ribs for the cooling circuit require the highest precision in terms of diameter accuracy, shape and position tolerances. The concentricity between different diameters is of huge importance.

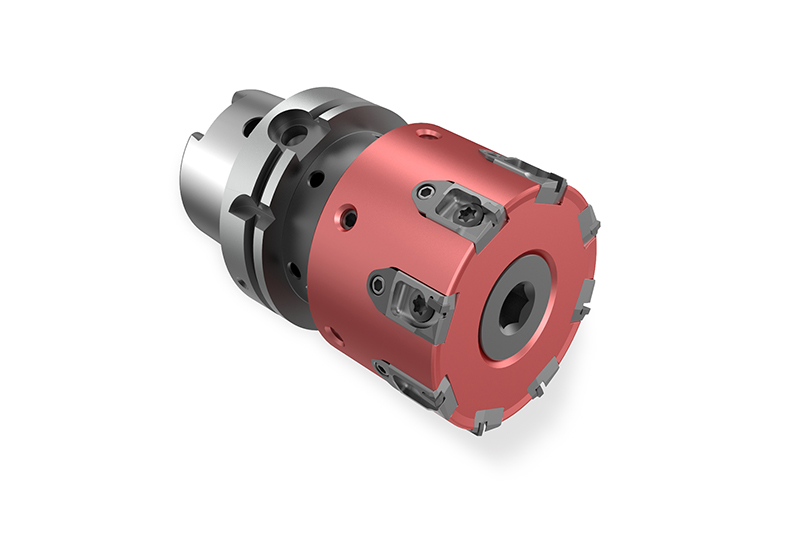

Pre-machining

Finish machining

Solutions d'usinage pour…