02.07.2021

Robot cell – an upgrade by two apprentices

What two apprentices made with a six-axis universal robotic system.

Without robots, nothing will function in the factory of tomorrow. Trained professionals to operate the smart helpers are essential as well. At MAPAL, the next generation is already getting their qualifications today. Two apprentices have converted and expanded a robot cell for the factory‘s own training centre.

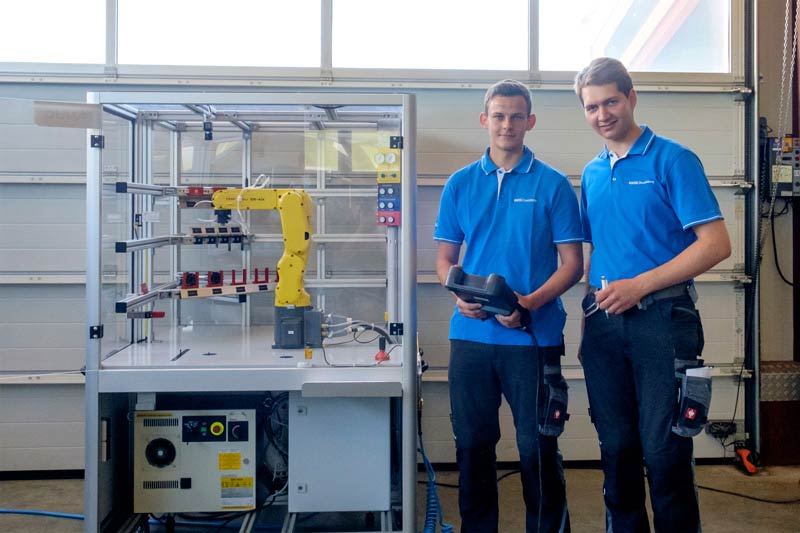

The MAPAL training centre is now home to the new robot cell. For Marvin Schuster (18) and Philipp Raab (19), both of whom are training to become mechatronics engineers, it is the perfect device to learn from. This is because a robot combines all the disciplines they will need to master in their future profession: mechanics, electrical engineering and computer science.

The machining cell arrives at the training centre as early as the beginning of 2020: a large glass box standing on a mobile trolley. The cell contains the robot as well as various components that a robot needs to carry out certain tasks. The device cannot be put into operation right away though, since, shortly after its arrival, the first lockdown due to the coronavirus pandemic takes place, and the team at the training centre has to teach all of the trainees in digital form for several weeks.

The robot system is examined

Plans come to life

The team decides to upgrade and rebuild the cell:

- It should be possible to simulate company-specific processes in tool production in preparation for the future use of robots in individual production areas.

- The robot should be also so easy to operate that even beginners without any previous knowledge can manage it.

It was a good year later before Marvin and Philipp, together with Martin Ernsperger, Tobias Dambacher and Uwe Hessler, Head of Training and Further Education at MAPAL, got to present the result of their work. For this purpose, they invited the representatives of the companies involved in the project as well as the teachers of the technical school to an on-site meeting. Marvin and Philipp had first dealt with the instructions for operating the robot cell. They added their own texts as well as explanatory pictures to make it easier to handle. „This gave us a good understanding of the subject matter.“ In the next step, they doubled the size of the robot cell‘s housing. Now, there was room inside for new components: a mountable machine door with collision detection, small format zero-point clamping systems, storage systems for grippers and tools, a tool change adapter, a laser measuring system, a second control cabinet as well as buttons and switches to complement the control panel.

Marvin and Philipp manufactured the mechanical parts themselves at the training centre. For the electronics and the programming of the software as well as for selecting additional components, the team worked closely with the Technical School of Aalen and the companies Fanuc and Mössner. Mössner is a supplier of special solutions in the fields of general machining, automation technology and robotics.

Mechanically, by controller and automatically

A worthwhile project

Marvin and Philipp are proud of what they‘ve achieved and were able to acquire a lot of knowledge about robots thanks to this project. The experts know how important this is. Automation and the use of robots will change production in the long term. This makes it all the more important to invest in preparing the next generation for this at an early stage. The topic must become more of an integral part in schools and training. „MAPAL has demonstrated how it can be done,“ said Jens Mühlegg, Technical Sales Support Universities and Education Centers at Fanuc. Thomas Dietrich, Director of Studies, and Jens Kinzler, teacher in the metal department, both of whom teach at the Technical School of Aalen, described the collaboration as a prime example of a successful learning cooperation. „This is real hands-on learning,“ Christian Kunz, Head of Research and Development at Mössner, commented on the successful modification.

The upgraded robot cell will be in widespread use now: all the trainees – whether they are training to become cutting machine operators, industrial mechanics or mechatronics engineers – are introduced to this innovative technology at MAPAL‘s training centre.

Meanwhile, Philipp and Marvin are about to take their final exams. Their training period was shortened by half a year to three years because of their good performance. Tobias Dambacher wants to advance his qualifications. In autumn, he will commence his training to become a technician in mechatronics and automation technology. He‘s already been accepted by the school.

Contact

Kathrin Rehor Public Relations Kathrin.Rehor@mapal.com Phone: +49 7361 585 3342