Multi-cutting edge high-performance reamers for large diameter ranges

To finely machine bores with large diameters within a defined tolerance range, users are often faced with the question: reaming or single point cutting?

Especially for machining from a diameter of 40 mm, MAPAL offers a programme of high-performance reamers with individual configuration options and HSK or module shank is available.

From the simple cutting ring to high-performance tools with straightforward insert change on site – for every application MAPAL offers a suitable solution for the high-accuracy and cost-effective machining of almost all workpiece materials.

Especially for machining from a diameter of 40 mm, MAPAL offers a programme of high-performance reamers with individual configuration options and HSK or module shank is available.

From the simple cutting ring to high-performance tools with straightforward insert change on site – for every application MAPAL offers a suitable solution for the high-accuracy and cost-effective machining of almost all workpiece materials.

HPR400 plus

No setting and four cutting edges significantly reduce cost-per-part

Efficient reconditioning was the focus of the development of the HPR400 reamers. The multi-bladed tools impress due to high cost-effectiveness thanks to fast application data and simple insert changing on site by the customer. This is possible due to the highly accurate insert seats. As such the logistics costs for transport to the manufacturer are completely eliminated. Tool stock and reconditioning costs are at a low level.

The indexable inserts of the HPR400 plus have four cutting edges. The cutting material is therefore optimally utilised. They are produced so accurately that they can be rotated or changed on-site by the customer's staff without problems. As a consequence the inventory of inserts can be further reduced, the reconditioning costs and therefore the cost-per-part drop.

HPR400

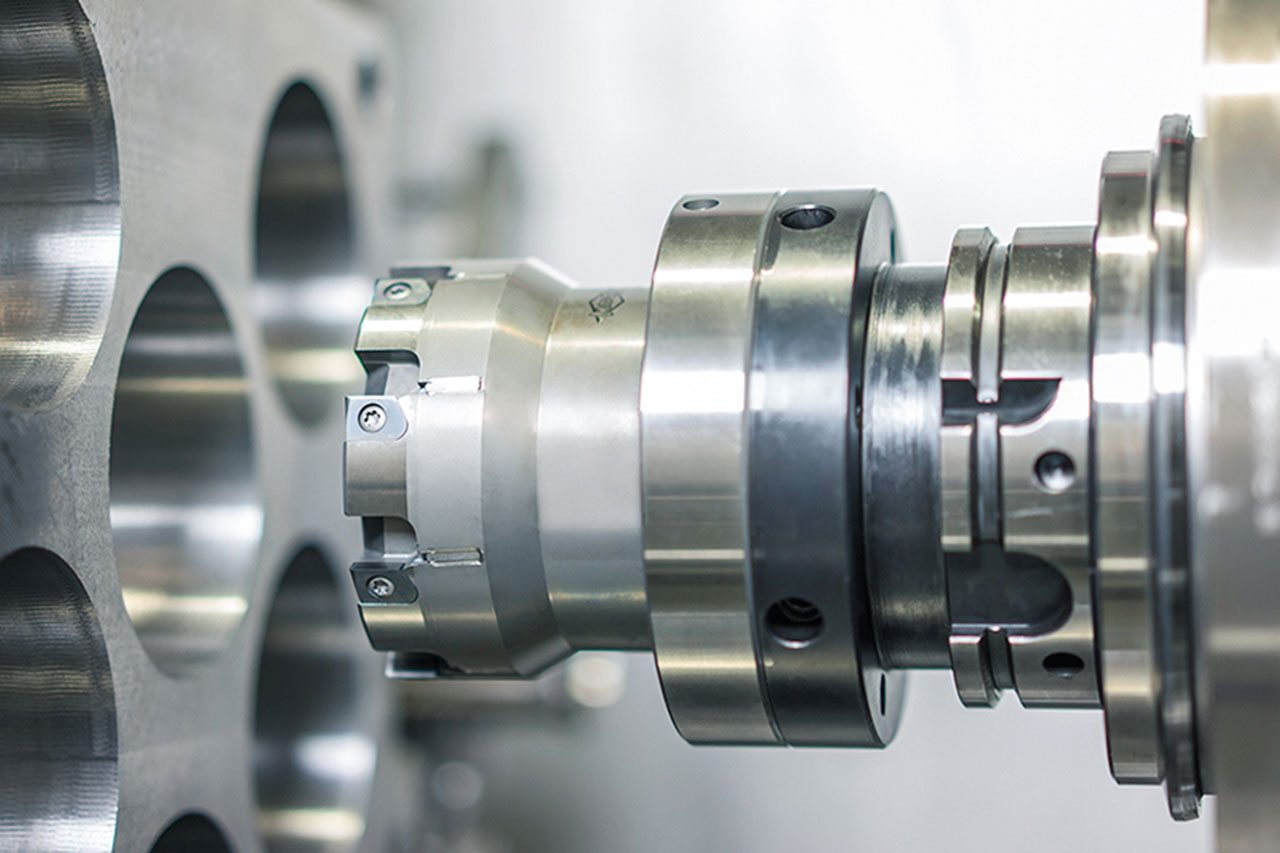

Simple insert change on site

Special, high-accuracy insert seats allow users of the HPR400 series to change the inserts on site using a torque wrench. The inserts cannot be fitted incorrectly, as only one installation orientation is possible and the inserts can be fitted at any position. As a result there is no setting effort, or the need to send tools for reconditioning. Users only need to have the inserts from MAPAL in stock. The quantity of tools required is low, as tool bodies do not need to be reconditioned. With minimal effort and a low number of tools in circulation, the user achieves high-accuracy bores with the HPR400.The cutting edges are optimally adapted to the material and the machining operation. HPR400 is available in the diameter range from 65 to 400 mm with HSK or MAPAL's own module adapter. MAPAL offers various inserts made of carbide without or with CVD coating, made of cermet and tipped with PCD or PcBN.

HPR300

Reduced costs due to innovative reconditioning

The HPR300 reaming system for large diameters convinces with the fact that the brazed tools can be re-tipped and re-coated far more quickly and less expensively.

Clamping jaws securely clamp the cutting edges as blanks. Then the diameter and cutting lead geometry are ground with high precision.

For reconditioning, the worn cutting edges can be easily and quickly replaced with new cutting edge blanks and again ground to the original quality with μ precision.

The tool body and in particular the shank retain their original, high accuracy. On the replacement of the cutting elements, the tool body is not subjected to any thermal loads whatsoever and complex cleaning processes are not required.

On average, brazed tools can be reconditioned a maximum of four times, while the HPR300 reamers can be re-tipped at least ten times.

As such, the tools pay for themselves already after the first few reconditioning cycles and provide significant cost savings over the entire service life without degradations in the performance compared with brazed tools.

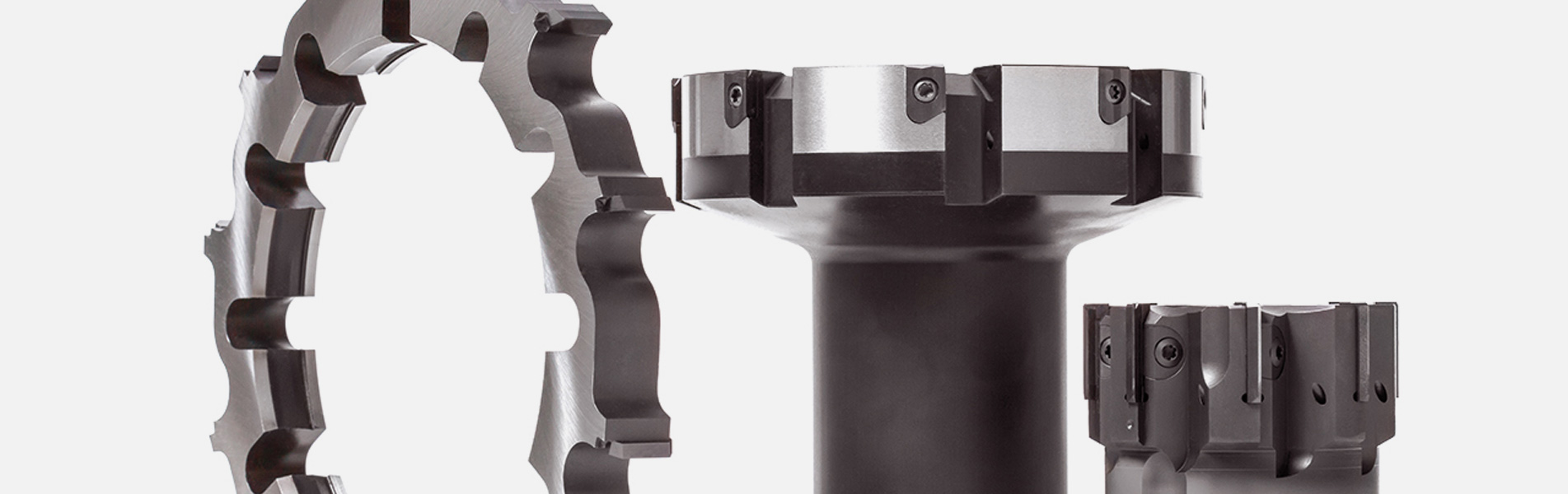

MultiCut reamers with re-adjustable cutting rings

Cutting rings with matching holder range

The MAPAL MultiCut reamers with re-adjustable cutting rings make it possible to fine machine bores down to a tolerance range below IT7.

Straightforward handling on setting and measuring the cutting rings as well as the possibility of combining with various holders are the advantages of this system.

Re-adjustable cutting rings are manufactured to half the stipulated tolerance.