Tools with guide pads

Highest accuracies with the MAPAL principle

Tools with guide pads have high accuracy and performance due to• the direct guiding in the bore using guide pads and

• the high quality of the precision-ground indexable inserts.

Particularly on the fine machining of bores, the requirements are exceptionally high on the cutting material, coating, cutting edge geometry and the quality of the grinding. Due to highly sensitive and accurate adjusting systems, the required diameter is produced to the μm from the first part.

The setting effort is significantly reduced by the EasyAdjust-System from MAPAL, as it is only necessary to set the diameter of the tools.

Single-bladed reamers

Precision-ground indexable inserts and guide pads at the best geometric positions are responsible for the machining of the workpiece material and the guiding of the reamer in the bore.

The product programme consists of two lines:

- Reamers with the WP cutting system with two cutting edges are characterised by special leads and an exact adjustability of both diameter and back taper.

- The HX cutting system with its hexagonal indexable insert offers six usable cutting edges.

Optimum backlash-free mounting of the inserts is guaranteed by the specially designed adjustment and clamping systems.

Twin-bladed reamers

Twin-bladed reamers allow the cutting speeds and feed rates to be increased compared with single-bladed reamers with guide pads.

The inserts are installed and adjusted so that they are staggered radially and axially. Dividing the cutting depth into a premachining and finishing cut with only a few hundredths of a millimetre chip thickness ensures very good surface finishes and long tool lives, even in materials that are difficult to machine.

Based on this principle, MAPAL also offers multi-cutting edge adjustable tools with guide pads designed, for example, according to the 4+2 principle, i.e. with four leading inserts and two finishing inserts for even higher feed rates.

Reamers with EasyAdjust-System

The goal of the development of the EasyAdjust-System was a drastic reduction in the setting effort for tools with guide pad technology.

The heart of the system is an innovative cassette that stably holds the indexable inserts with their six or four cutting edges without any play. The back taper on the minor cutting edge is already integrated into this cassette, thus eliminating this setting effort.

Due to the exact guidance in the cassette on a precision guide pin, the back taper remains unchanged even during diameter setting.

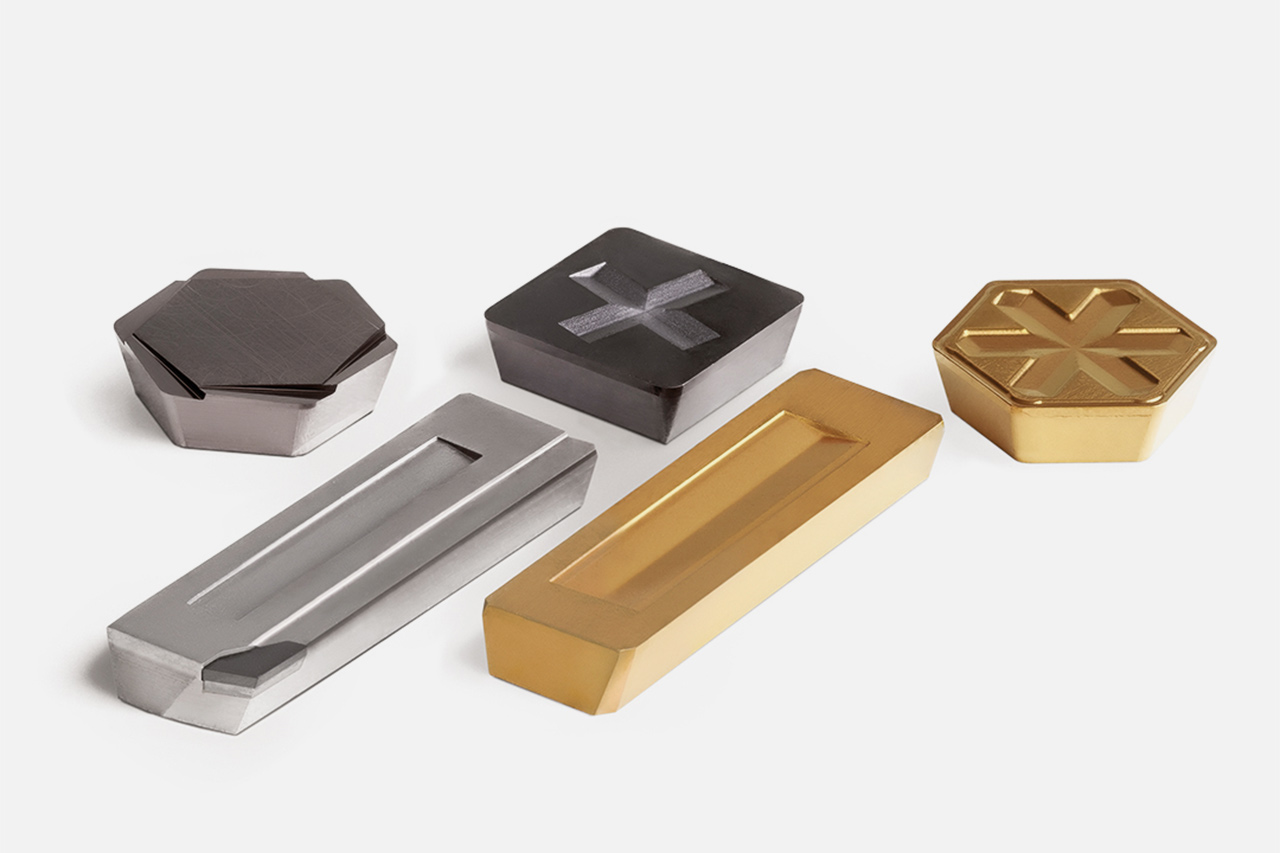

Indexable inserts

Along with the selection and design of the tool construction, the correct cutting material is of great importance for the quality and cost-effectiveness of machining.

Carbide, cermet, coatings, PCD and PcBN, the entire range of modern cutting materials is available from MAPAL for every workpiece material and for every machining task.

The latest manufacturing technology employed in the production of the indexable inserts today enables any chip former and chip breaker shape to be achieved – even on extremely hard cutting materials such as PcBN and PCD.

External and taper reamers

External reaming tools allow outside diameters and shafts to be machined efficiently and to the μm.

The principle of MAPAL external reaming is based on optimally absorbing and dispersing the cutting forces using guide pads so that no displacement forces and bending moments are exerted on the workpiece.

Taper fits in machine engineering place very high demands on surface finish, lead accuracy and circularity deviations to ensure the crucial contact ratio of the fit.

The MAPAL principle is also applied to taper reamers to machine reliably to the tightest tolerances.

Custom solutions

The primary application for guide pad-tools is mostly in large-scale series production. In addition to its standard programme, MAPAL also offers custom tools specially matched to the customer's application.

By means of special geometries, cutting materials and coatings, the tool can be designed for optimal machining results and high cost-effectiveness.

Tool combinations with other tool technologies enable customers to undertake complex tasks cost-effectively with only one tool.