25.03.2024

All-inclusive package for end machining

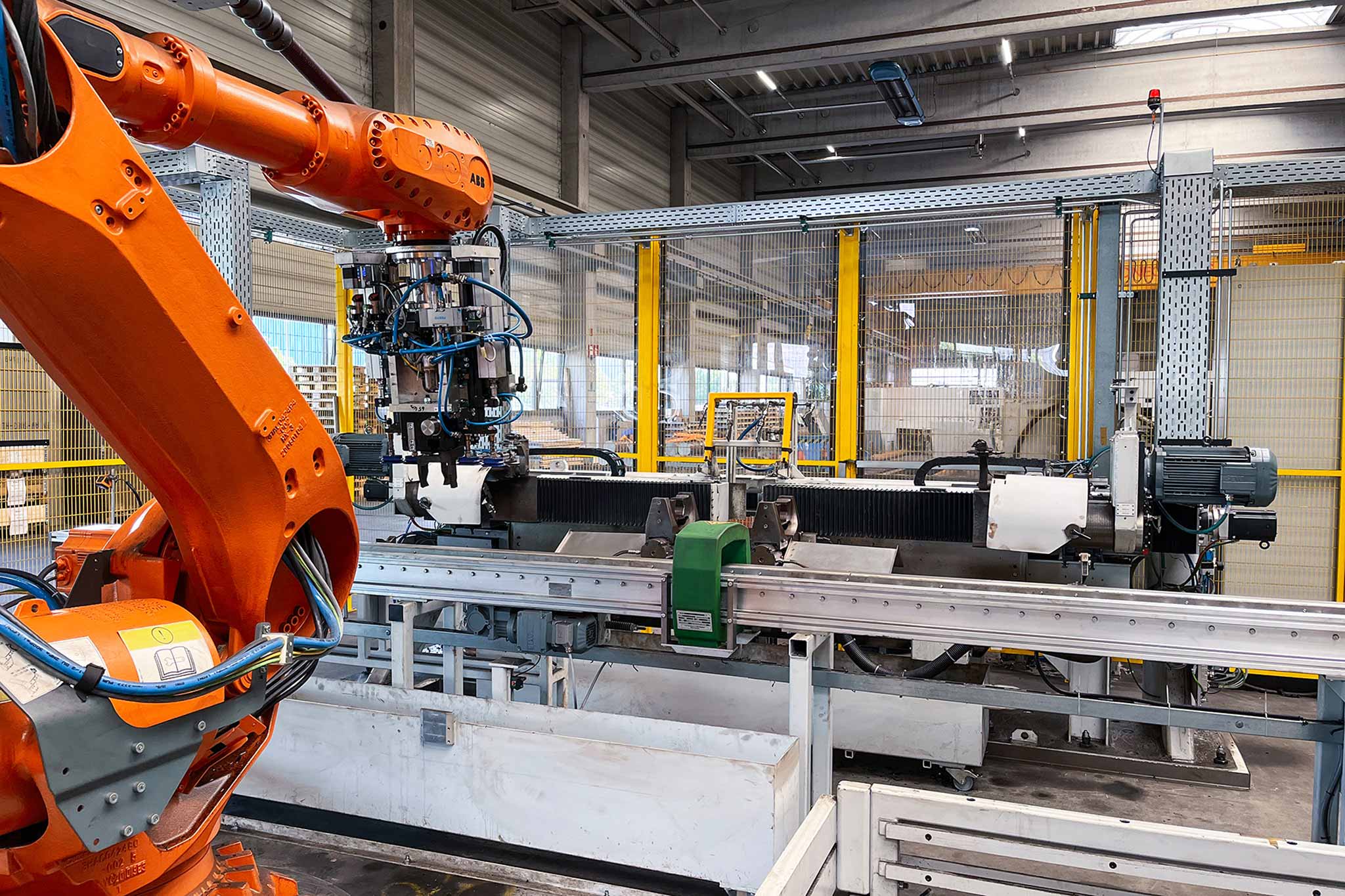

Regional roots, international success. This applies to the three companies GABO STAHL, Mössner and MAPAL equally. It is only logical that a cooperation benefits everyone: For the end machining of round steel, GABO STAHL now relies on an automated solution from Mössner, which in turn works with MAPAL tools.

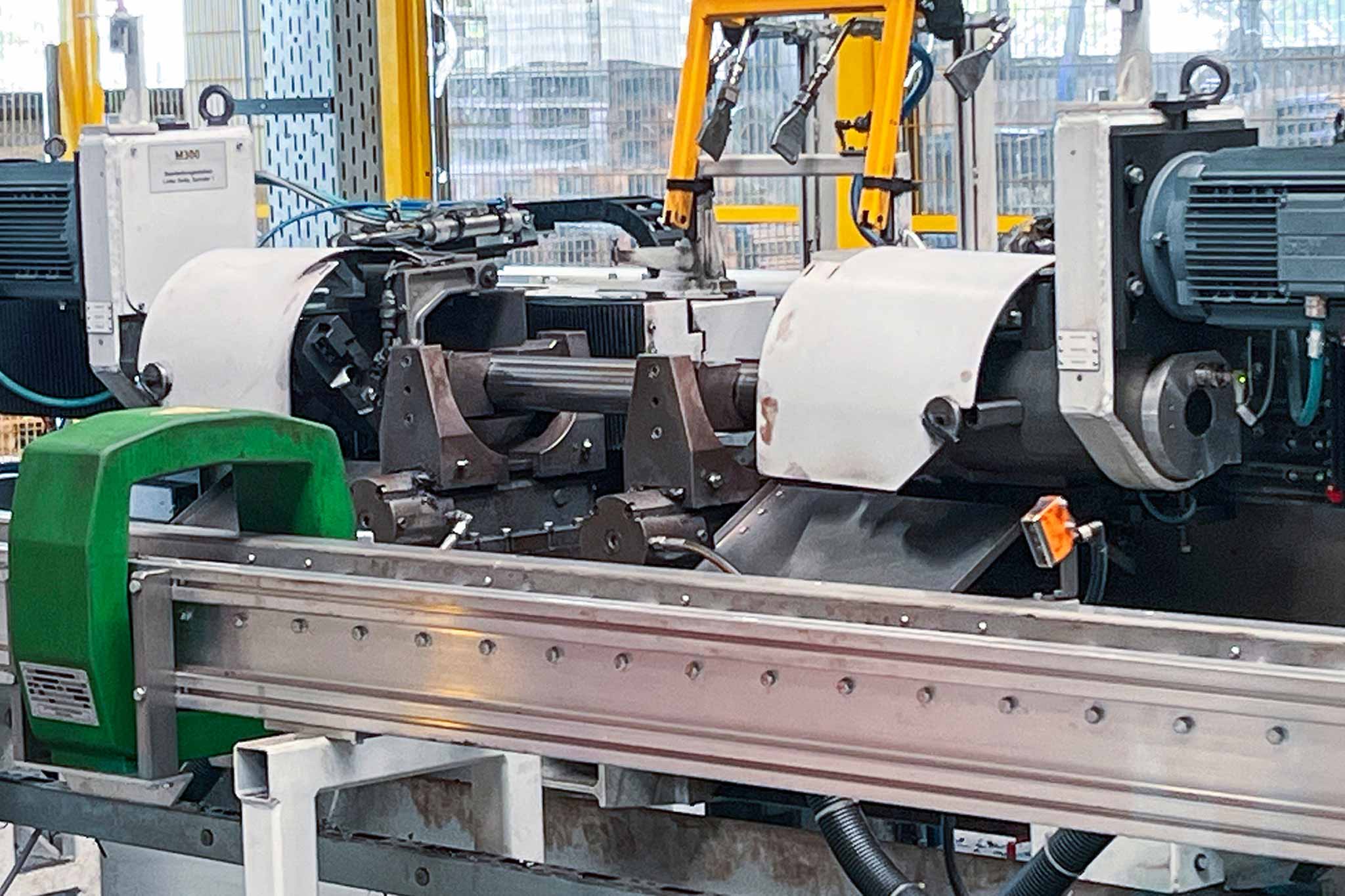

Sawn round steel bars with lengths of nine millimetres are just as much a part of GABO STAHL's portfolio as round steel bars with a length of six metres. There is a large customer base, and the products are used for a wide range of applications – from use in electrical and hydraulic parts production to large bolts for wind turbines. GABO STAHL is not only a steel trader, but also a steel processor. The company based in Essingen near Aalen was looking for the right system to machine the ends of all round steel bars with a diameter of 30 to 100 mm and a length of 300 to 2000 mm. As GABO STAHL CEO Thorsten Maier points out: “We like to supply our customers with the primary material ready for use and undertake as much preparatory work as possible.”

At GABO STAHL, these products are not usually manufactured in large series. Business is mainly dominated by small series. “Our production equipment has to be able to work just as flexibly as we do”, explains Maier. The problem with this is that “Although we perform machining tasks for our customers, we don’t have any trained machinists working for us.” Therefore, in addition to the requirement for flexibility in terms of different dimensions and steel grades, there is also a need for the simplest possible operation.

Working together as equals

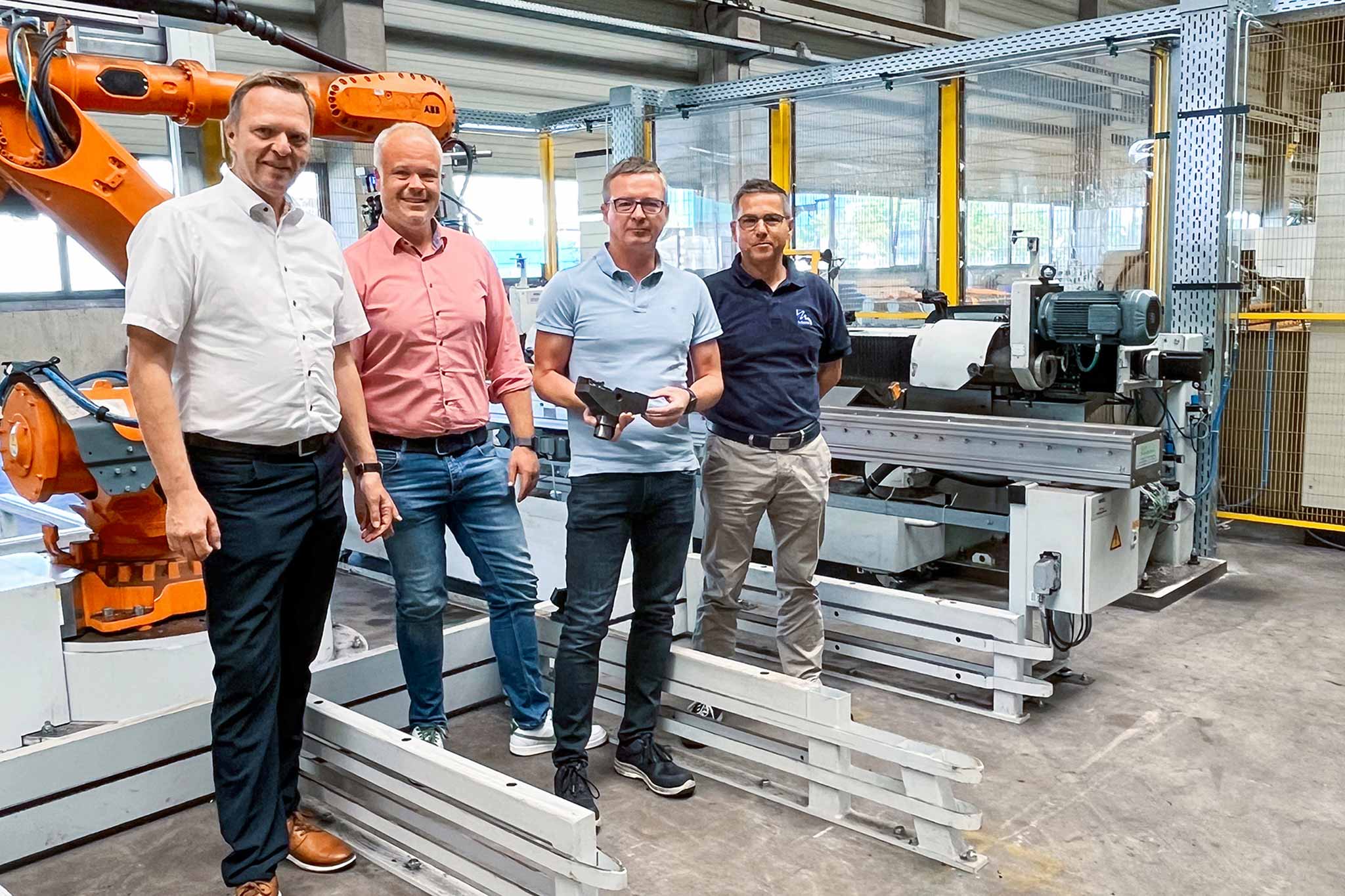

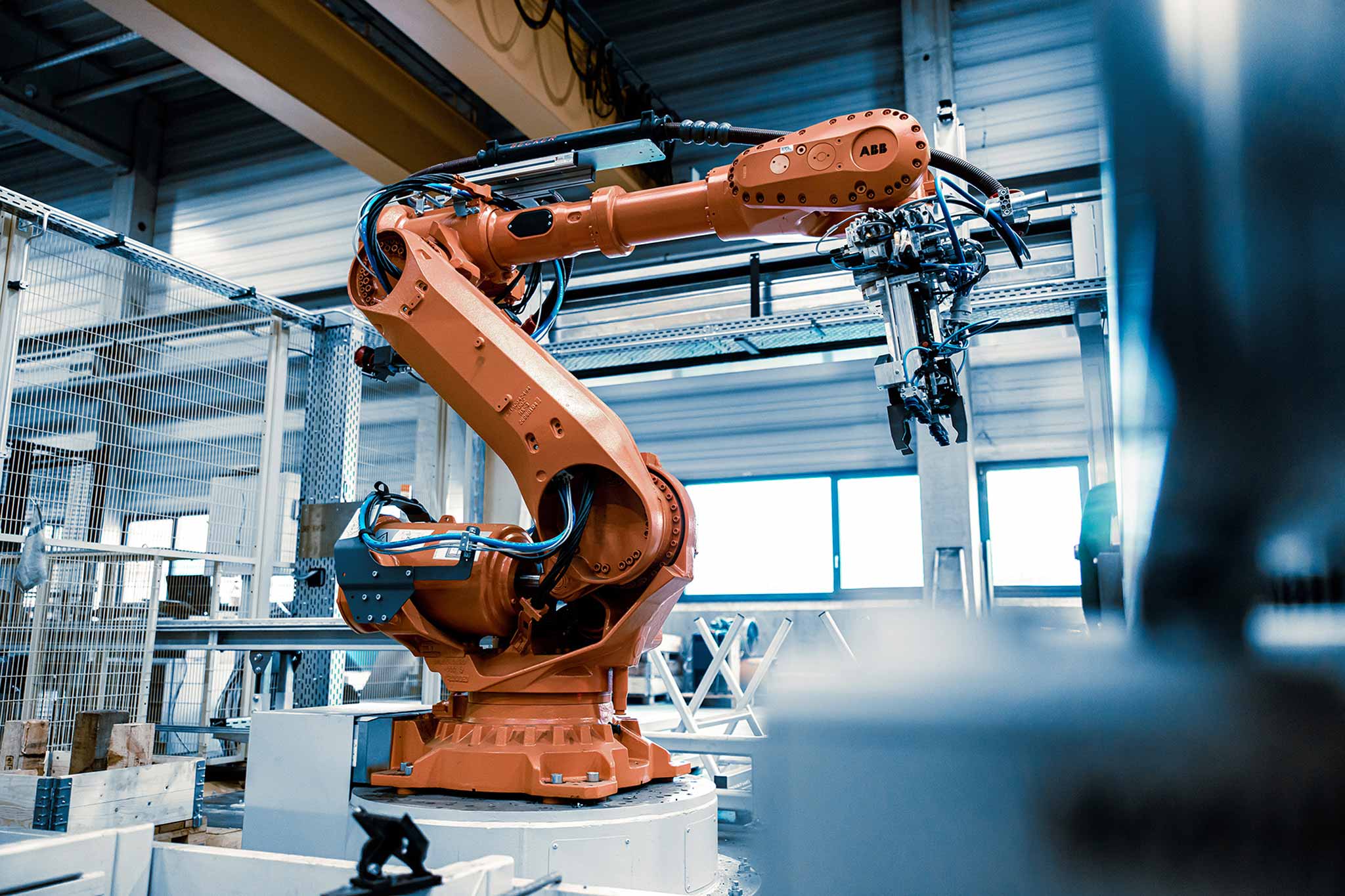

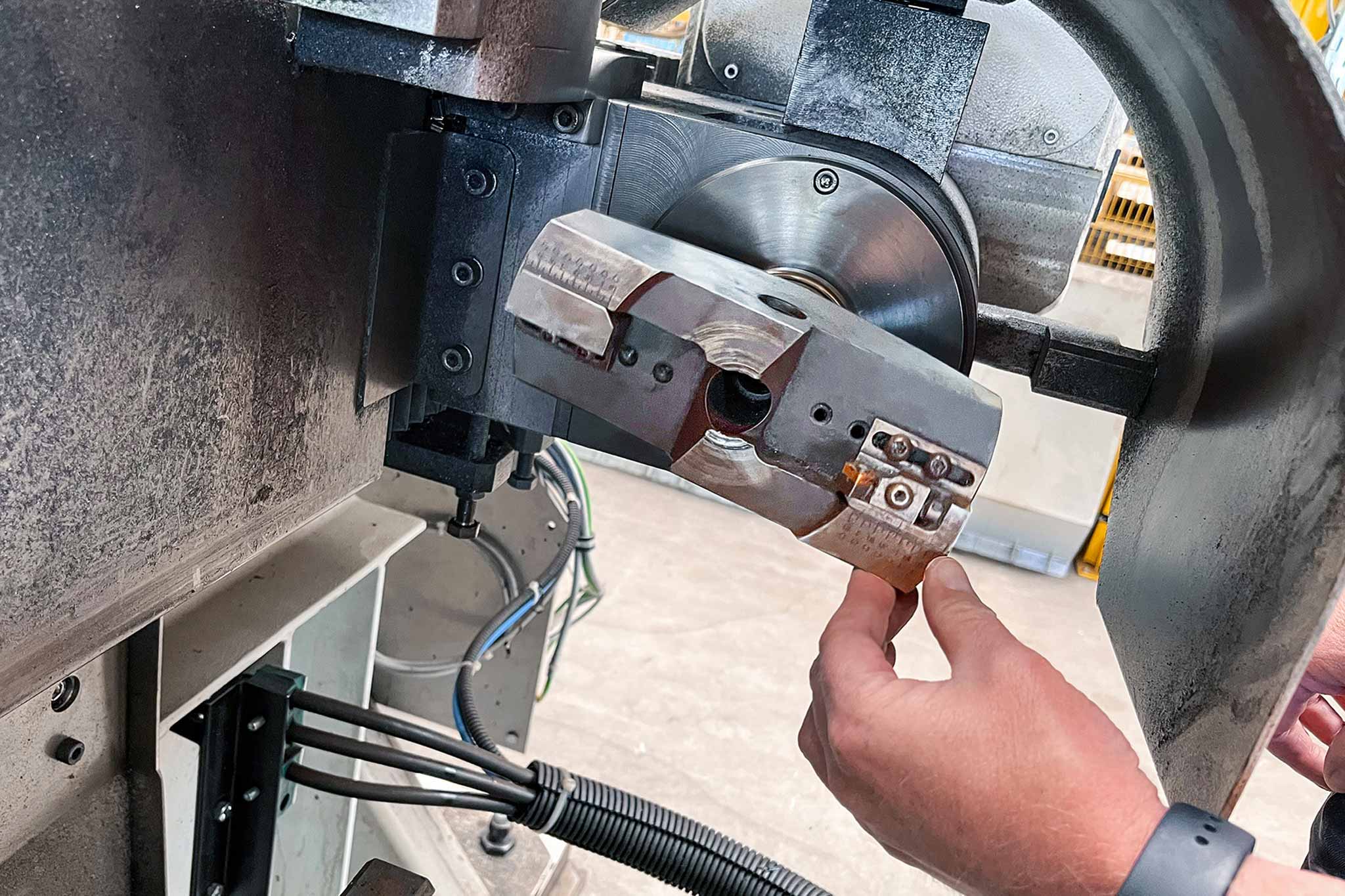

MAPAL and Mössner worked together closely for around eight weeks on the system that is now installed at GABO STAHL. Marc Wagner, Technical Consultant at MAPAL, recalls: “The tool for facing, chamfering and centre drilling different types of steel and diameters was a major challenge.” The various steel grades were the main source of development work. The engineering steels and tempering steels to be machined are usually specified by GABO STAHL's customers in terms of chemical composition and mechanical values.

“We get everyone round the table, work things out, think creatively and find joint solutions”, Fuchs describes the development process. “Once the right tool has been found and designed, we build the rest of the machine around it.” After all, the tool is at the centre of the system.

Assured high quality in a significantly shorter time

“The system from Mössner is a great asset for us”, says Thorsten Maier. Before production started with the new machine, all machining operations were performed by hand. GABO STAHL thus not only saves a huge amount of time with machining, but also ensures the consistently high quality of the machined ends. And: “The system also saws, measures, marks, demagnetises and packs the workpieces”, says Maier. An all-inclusive package supplied by Mössner and MAPAL. The staff who work with the machine every day are also impressed by how easy it is to use and by the ability to switch over to new components quickly and straightforwardly.

The smooth running of this joint project at GABO STAHL is no accident. “We work successfully with Mössner not only here in Baden-Württemberg, but all over the world”, explains Marc Wagner. For example in Mexico, where many car manufacturers and suppliers operate plants and rely on the combined solutions of both companies.

Contact

Kathrin Rehor Public Relations Kathrin.Rehor@mapal.com Phone: +49 7361 585 3342