Development of customised diamond coatings

Longer tool life and improved process reliability

With its in-depth knowledge in the field of coating technology, MAPAL now also develops extremely hard and wear-resistant diamond coating for machining materials such as CFRP, ceramics, graphite and aluminium alloys. MAPAL’s machining solutions achieve a longer tool life and more process reliability especially for applications in the automotive and aero- space industry, for die and mould and in medical technology. After all, the individual components are perfected tuned to one another be- cause everything comes from a single source at MAPAL – from tool design and the selection of substrates to the coating. Tools can be de- signed even more precisely to meet customers’ requirements.

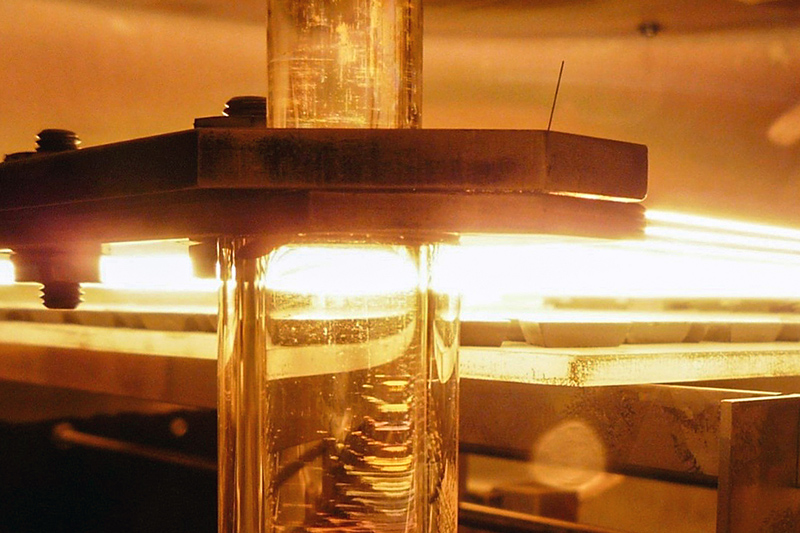

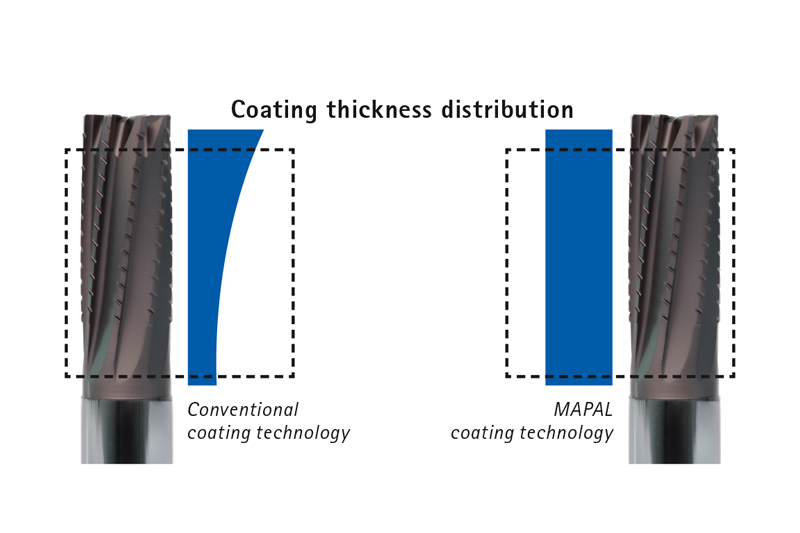

To produce the new coating for milling and drilling highly abrasive material, MAPAL is using hot-filament CVD (abbreviated HF CVD) to synthesise pure diamond coating. The HF CVD process produces layers with almost uniform thickness, which MAPAL uses in developing its OptiMill-Composite-Speed-Plus. Conventional CVD coatings are not suitable for coating shank tools because the tool lengths and the high coating temperatures usually result in length distortion.

OptiMill-Composite-Speed-Plus

MAPAL coating

- ptimal distribution of coating thickness

- Increased diamond thickness for maximum tool life

Your direct contact

Contact person

Tim Rohmer Product and Application Management tim.rohmer@miller-tools.de Phone: +49 8337 727-4518