Solutions for Fluid Technology

Everything depends on the main bore

Manufacturing valve housings is the supreme discipline in the hydraulics world. For many years, MAPAL’s expertise has been in demand for the spool bore. The gap dimension with the slide depends on the accuracy of this bore, which is very narrowly defined in modern hydraulic valves, so that the hydraulic oil can only flow in the required direction. The roundness, straightness and surface finish of this bore are also crucial.

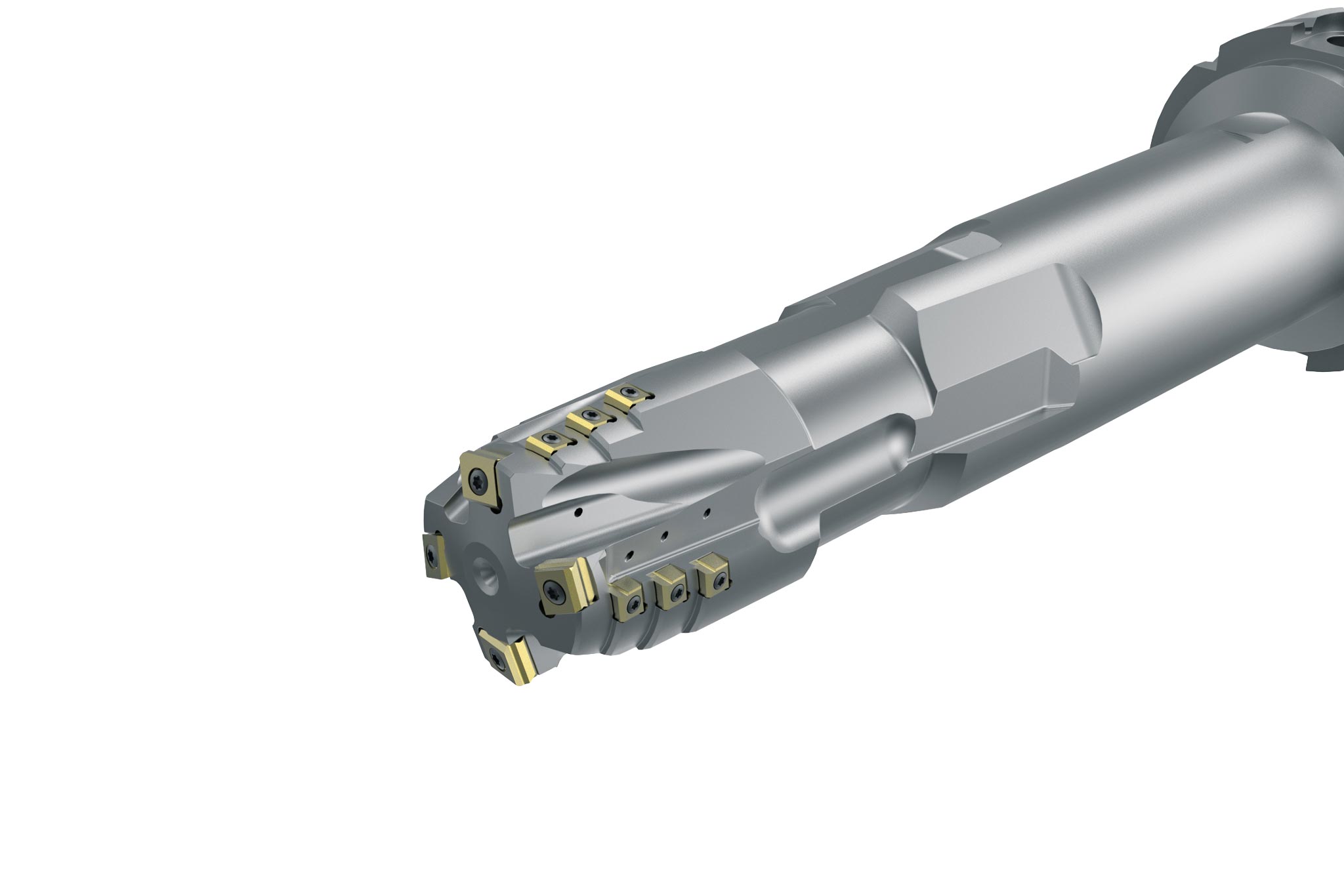

The first machining step takes the varying quality of the blank parts into account. Since the pre-cast bores are relatively imprecise, a precise pilot bore must first be created in the first ridge. This lays the foundation for creating a good cylindrical form in the subsequent machining steps. Next, a solid carbide tool or, in the case of larger parts, a tool with indexable inserts passes through the entire bore. What the pilot drill has created for the first ridge is now produced along its entire length. To prevent ring formation in the hollow chambers due to chips, MAPAL ensures a soft cut during machining by using tangential technology. This can eliminate the need for a separate washing cycle in the process.

After this pre-machining, the classic fine boring tool is used, finishing the bore extremely precisely. It has an adjustable cutting edge and guide pads, which prevent the tool from being displaced from ridge to ridge. This produces a high degree of straightness and an exact cylindrical form.

The bore quality can usually be improved to such an extent that the sometimes still necessary three-stage honing process can be reduced to a one- or two-stage honing process, or honing can even be eliminated altogether. However in cases where three stages are still needed, this process is considerably faster thanks to the good pre-machining.

High cost-effectiveness with standard tools

Efficient machining with tangential boring tool