Series production of scroll compressors

Scroll compressors have been successfully used in air-conditioning applications and heat pumps for quite some time. They stand out thanks to their high cooling capacity and reliability as well as excellent energy efficiency and low noise emission. With electrification, they are also increasingly finding their way into the automotive sector, primarily as refrigeration compressors for air conditioning systems.

At the heart of each scroll compressor are two interlocking spirals (fixed scroll and moving orbiting scroll) whose opposing movements compress the medium. The level of efficiency depends, in particular, on how precisely these parts are manufactured. In this regard, the requirements on form and position tolerances lie within the range of a few μm.

MAPAL offers the complete process for machining scroll compressors from a single source. Three specific machining operations on an aluminium scroll compressor for use in an electrified vehicle are presented as examples.

At the heart of each scroll compressor are two interlocking spirals (fixed scroll and moving orbiting scroll) whose opposing movements compress the medium. The level of efficiency depends, in particular, on how precisely these parts are manufactured. In this regard, the requirements on form and position tolerances lie within the range of a few μm.

MAPAL offers the complete process for machining scroll compressors from a single source. Three specific machining operations on an aluminium scroll compressor for use in an electrified vehicle are presented as examples.

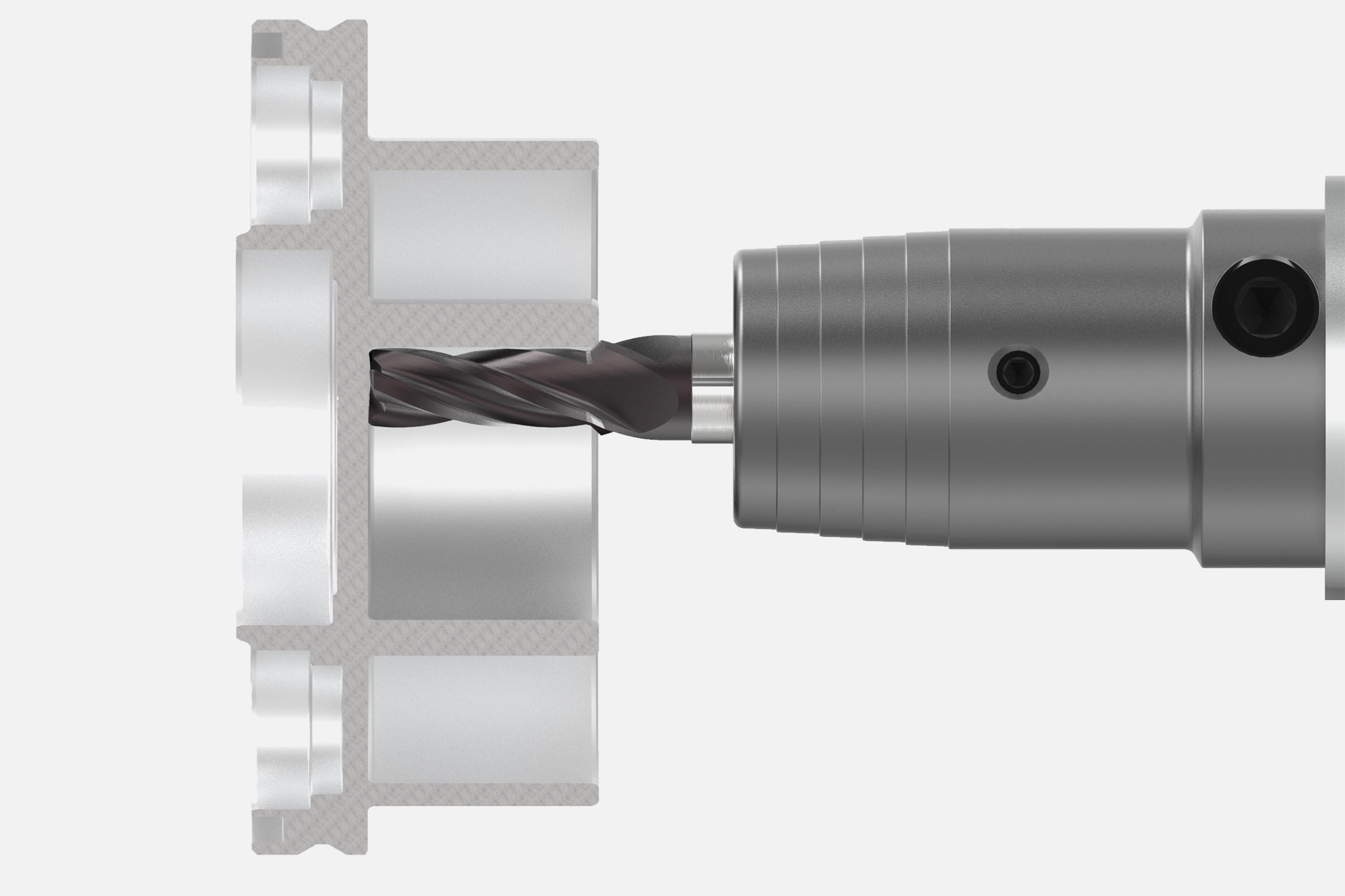

High-precision spiral shapes

The machining of the spiral poses a particular challenge as it must have a defined squareness of less than 0.02 mm and an average roughness depth in the single-digit µm range. Despite these requirements in addition to the thin walls and the depth of the part, the finishing process should be carried out in one process.

The pre-machining and fine machining of the spirals is carried out with two three-edged milling cutters made of solid carbide. The decisive factor is the high accuracy of the tools, which ensures that the tolerances in radial and axial run-out are less than 10 µm. The extremely sharp cutting edges ensure high dimensional accuracy. The reinforced core diameter makes them particularly stable. Finely finished chip flutes ensure safe and fast chip removal.

The finishing milling cutter is fitted with an additional chamfer on the diameter. The machining of the base, wall and the chamfer on the front face of the part can be carried out in a single step, and the tool reliably satisfies the tight tolerances with regard to perpendicularity and surface.

The pre-machining and fine machining of the spirals is carried out with two three-edged milling cutters made of solid carbide. The decisive factor is the high accuracy of the tools, which ensures that the tolerances in radial and axial run-out are less than 10 µm. The extremely sharp cutting edges ensure high dimensional accuracy. The reinforced core diameter makes them particularly stable. Finely finished chip flutes ensure safe and fast chip removal.

The finishing milling cutter is fitted with an additional chamfer on the diameter. The machining of the base, wall and the chamfer on the front face of the part can be carried out in a single step, and the tool reliably satisfies the tight tolerances with regard to perpendicularity and surface.

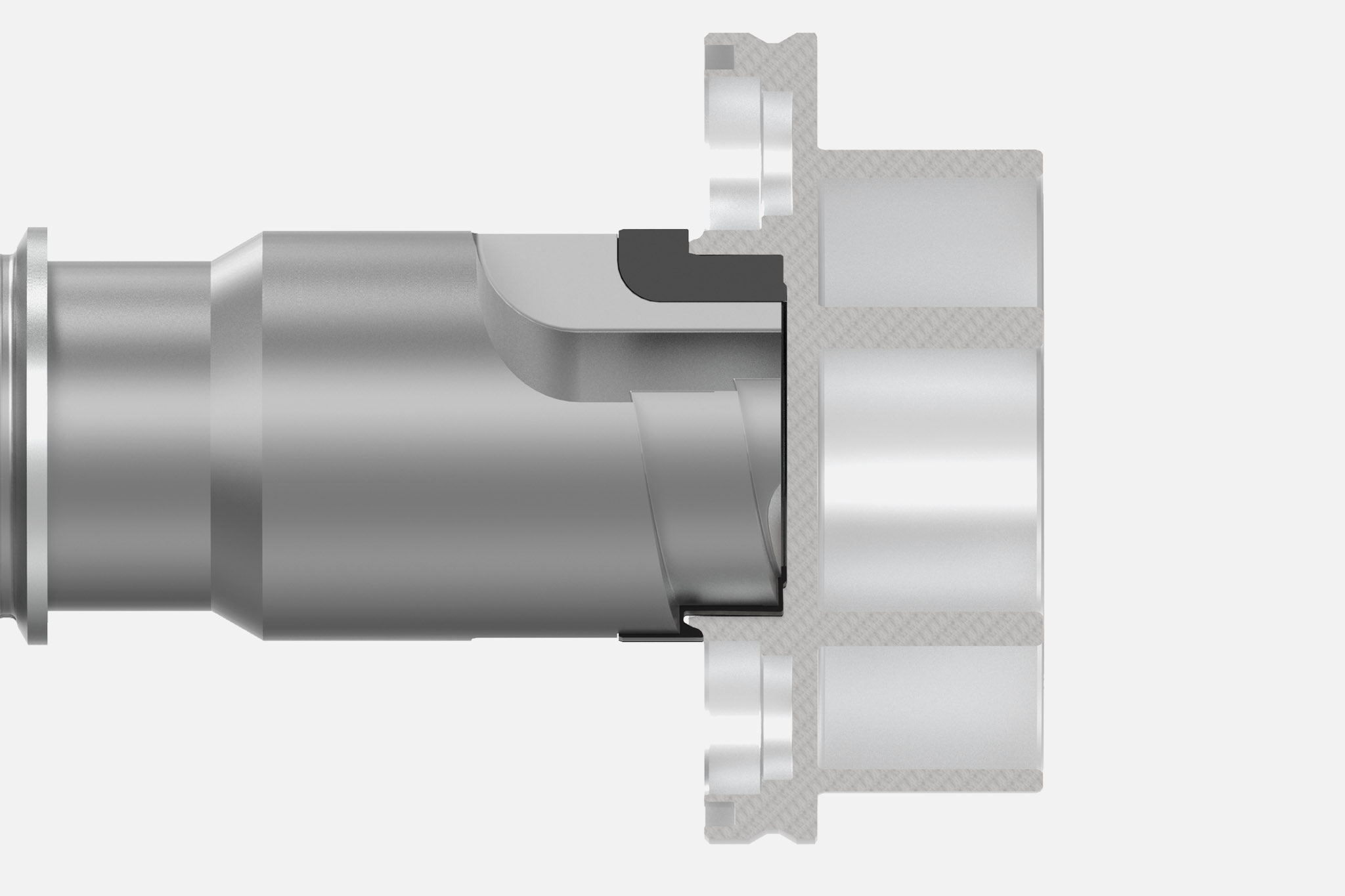

Precise bearing bore

A shaft drives the moving scroll in orbit. It is supported by a roller or ball bearing, whereby the bearing bore is decisive for the positioning of the two spirals relative to each other.

Pre-machining is carried out by circular milling with a triple-fluted PCD milling cutter. The flange is then milled over. The fine machining of the bearing bore is carried out with a double-edged PCD boring tool in two steps. In the first step, the large diameter of the bearing bore is machined, the second step finishes the flange. To reduce the cutting forces, distribution of the cut takes place.

Pre-machining is carried out by circular milling with a triple-fluted PCD milling cutter. The flange is then milled over. The fine machining of the bearing bore is carried out with a double-edged PCD boring tool in two steps. In the first step, the large diameter of the bearing bore is machined, the second step finishes the flange. To reduce the cutting forces, distribution of the cut takes place.

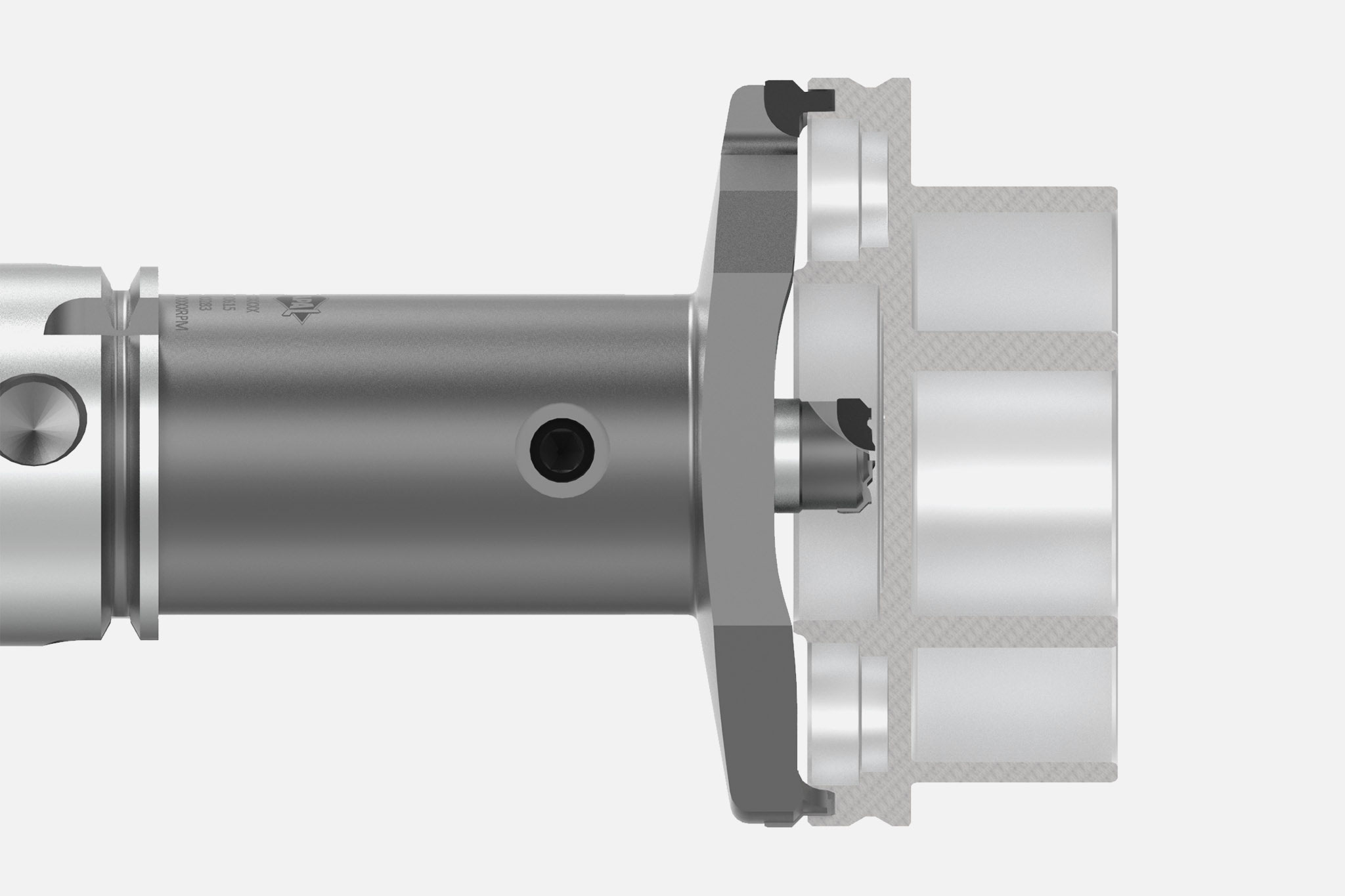

Recesses for sealing elements

Additional sealing elements can be used to minimise the flow of refrigerant from the high to low pressure side, to seal the connection bores or to seal the entire system. Recesses are necessary for connecting these elements. The pre-machining and fine machining of the recesses is carried out with double-edged PCD boring tools. The distribution of the cut reduces the cutting force.

The fine machining tool is designed as a combination tool, and this also allows the recesses at the connection bores on the back of the fixed scroll to be machined. Chip breakers on the PCD cutting edges provide more chip control and increased process reliability.

The fine machining tool is designed as a combination tool, and this also allows the recesses at the connection bores on the back of the fixed scroll to be machined. Chip breakers on the PCD cutting edges provide more chip control and increased process reliability.

Your direct contact

Contact person

Matthias Winter Department manager matthias.winter@mapal.com +49 7361 585 3360