28.05.2019

MAPAL Expert Day highlights potential in steel and cast machining

150 customers and interested parties in machining obtain information from the Aalen-based precision tool manufacturer

Have the possibilities for increasing efficiency in the machining of steel and cast materials been exhausted? Not in the slightest, as the “MAPAL Dialog” Expert Day proved. Scientists from Dortmund Technical University, users and the tool specialists from MAPAL presented new solutions with great potential.

Optimal process strategy and key influencing factors

Maximum performance and process reliability with intelligently optimised tools

Specialists from MAPAL highlighted the specific advantages provided by optimised tools when machining steel and cast materials. Ulrich Krenzer, Managing Director of the Centre of Competence for Solid Carbide Tools, demonstrated how a three-edged drill performs during cast and steel machining. It can machine an axial piston pump in half the time compared to a double edge tool. At the same time, it doubles the number of parts from 5,400 to 10,800.

Jochen Schmidt, Product Manager Clamping Technology, explained additive manufacturing and its advantages in hydraulic clamping technology. In order to achieve better cutting parameters and higher process reliability, the specialists use additive manufacturing to place the clamping range closer to the point of action and increase stability. “This has an enormous impact on the cost per part,” stressed Schmidt.

Special milling tools instead of a new machine

Markus Zapke, Team Leader for Tooling, Equipment & Processes at the Siemens gas turbine plant in Berlin, reported on the challenge of machining the blade groove of a large gas turbine. Siemens usually relies on reaming for this slot machining; a machining process for the production of inner and outer profiles. “In this case the slots were too deep, we would have had to buy a new machine,” said Zapke. As an alternative, MAPAL has developed custom tools for milling with which the slot can be machined smoothly.

Other presentations dealt with increasing tool life through high-performance coatings and new tools as well as methods for chip removal. Another topic that was discussed was the digitisation of production processes and the intelligent networking of machines.

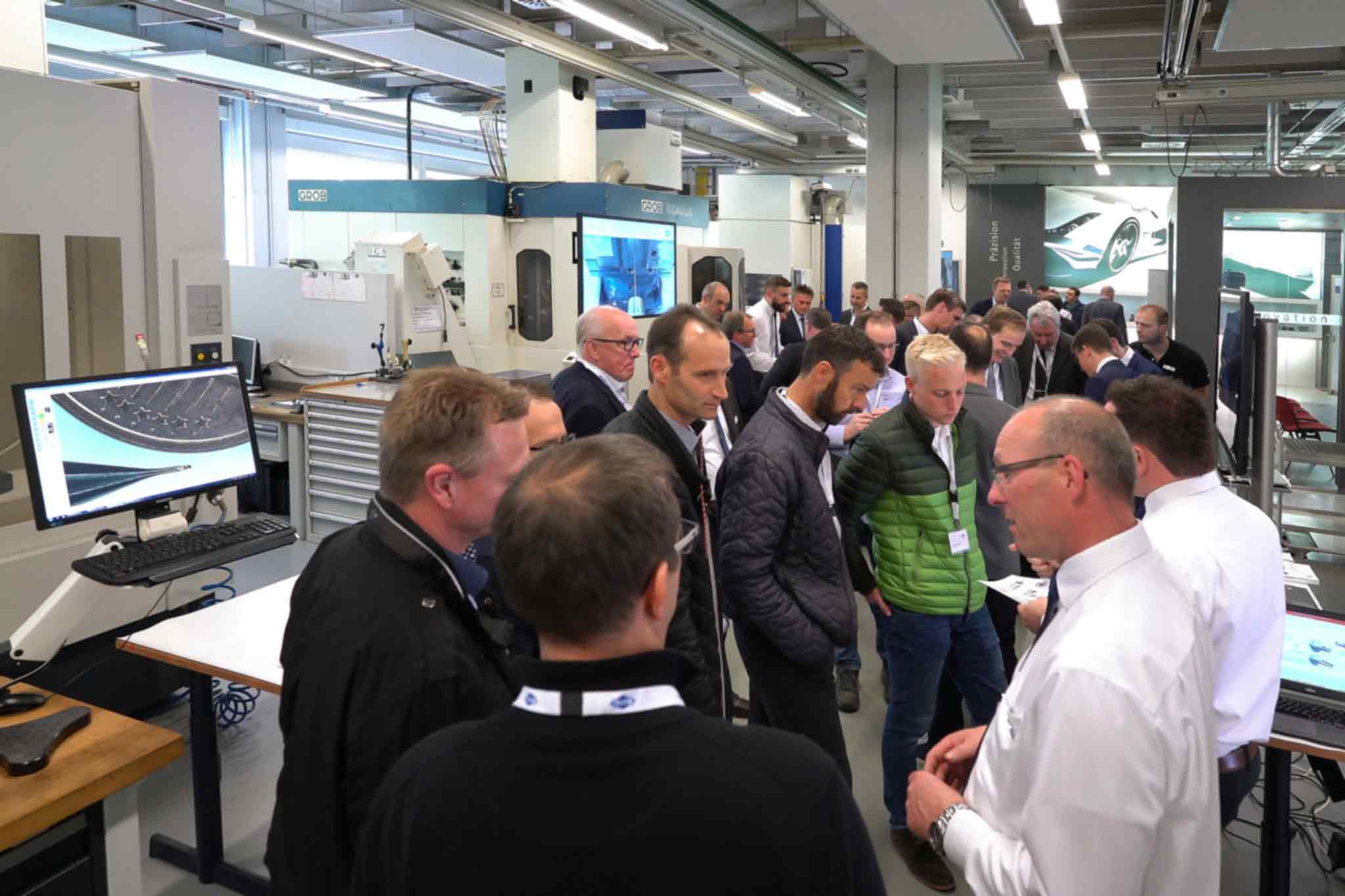

Machining live at the machine

In the Research and Development Centre, the participants had the opportunity to see how the tools performed when machined live. MAPAL presented trochoidal milling as well as high-performance machining in the field of drilling and milling. Another highlight was a new chip breaker for steel and the milling cutter range with radial ISO indexable inserts for steel and cast machining. Customers and interested parties used the opportunity to obtain information from the development engineers and technicians and have some in-depth discussions with them.

During the breaks, there was also a lively exchange between the participants and the speakers, product specialists and Dr Jochen Kress. The accompanying product exhibition showed other sectors and fields of application in which MAPAL is active. These include die & mould sector, digital tool logistics and the field of e-mobility.