10.09.2025

75 years of MAPAL

In a history now spanning 75 years, the family business MAPAL has gone from humble beginnings to an international group with a global reputation. From the very beginning, the tool manufacturer’s company history has been characterised by continuity and an innovative spirit that was nourished by Swabian ingenuity and creativity, as well as by the entrepreneurial courage of the owner family Kress. Close contact with customers and a reliable sense for what will matter in future continue to shape the company’s culture to this day.

Die Unternehmensgründung im Jahr 1950 verlief durchaus ungewöhnlich. Der promovierte Volkswirt Dr. Georg Kress war als Steuerberater tätig, als er die Gelegenheit bekam, die in wirtschaftliche Schwierigkeiten gekommene Firma eines seiner Mandanten zu übernehmen. Obwohl er von Technik, Gewindeschneidwerkzeugen und Schneideisen nichts verstand, kaufte er die „OBA Präzisionswerkzeugbau“ von Otto Betzler. Er veräußerte dafür seine gut laufende Steuerberaterkanzlei in Aalen und wurde als Unternehmer tätig.

Der neu entstandene Firmenname MAPAL steht für „Maschinen- und Präzisionswerkzeugfabrik Aalen“ und zeugt davon, dass in den Anfangsjahren auch Holzbearbeitungsmaschinen hergestellt wurden. Weil in den beengten, einfachen Räumlichkeiten an der Oberen Bahnstraße in Aalen eine wirtschaftliche und effiziente Produktion der Profilfräsmaschinen auf Dauer nicht möglich war, trennte MAPAL sich sehr schnell wieder von diesem Geschäftsbereich. Man konzentrierte sich auf Gewindebohrer, -schneideisen und -walzrollen, was den Beginn des heutigen Werkzeugprogramms markierte.

Mit einer Reibahle fing alles an

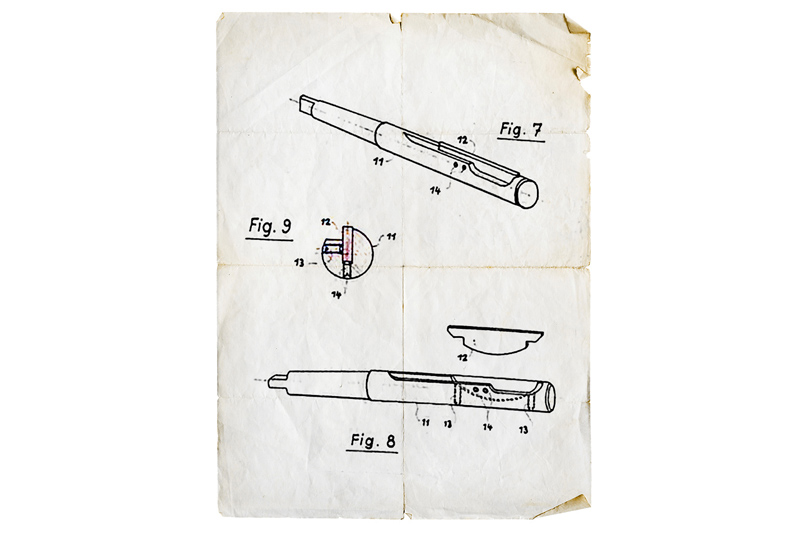

Um die anfänglichen Probleme zu überwinden, setzte Dr. Kress auf Forschung und Entwicklung. In mühsamer Tüftelei wurde die Reibahle verbessert, unter anderem wurden dafür zwei Führungsleisten asymmetrisch am Umfang des Reibahlenkörpers eingebracht. Die erste von MAPAL entwickelte Einschneiden-Reibahle mit Führungsleisten aus Hartmetall wurde 1954 patentiert, 1962 folgte das Patent für die Reibahle mit Wendeschneidplatten aus Hartmetall.

Beide Innovationen bildeten die Basis dafür, die Reibahlen in den folgenden Jahren zu einem höchst attraktiven Hochleistungswerkzeug zu entwickeln. Die Bohrungsfeinbearbeitung wurde zum Aushängeschild von MAPAL.

Als Dr. Dieter Kress 1969 in das Familienunternehmen eintrat, war der Sohn des Firmengründers bestens auf seine künftigen Aufgaben vorbereitet. Anders als sein Vater war er in der Technik zuhause. Bereits an seinem ersten Arbeitstag bei MAPAL konstruierte er eine neue Klemmung für Wendeschneidplatten. Sie wurde patentiert und bildet im Prinzip bis heute die Technologie der Klemmung der Wendeschneidplatten in den Reibahlen von MAPAL.

Weitsichtige Produktentscheidung

Nachdem er 1974 die Geschäftsführung übernommen hatte, machte sich Dr. Dieter Kress zügig an die Umgestaltung des Produktportfolios. Der Geschäftsbereich Gewindebohrer und Gewindewalzrollen wurde aufgegeben, um sich ausschließlich auf die Produktion der Reibahlen zu konzentrieren. Dies geschah zu einem Zeitpunkt, als MAPAL zwei Drittel seines Umsatzes mit Gewindewerkzeugen erwirtschaftete. Doch hinter dem Plan steckte unternehmerische Weitsicht. Bei den älteren Produkten gab es kaum Potenzial, sich von zumeist größeren Herstellern zu differenzieren, die dazu preisgünstiger produzieren konnten. Die Einschneiden-Reibahle hingegen war etwas ganz Spezielles, für das es keinen direkten Wettbewerb gab. Allerdings musste der Markt dafür erst erschlossen werden.

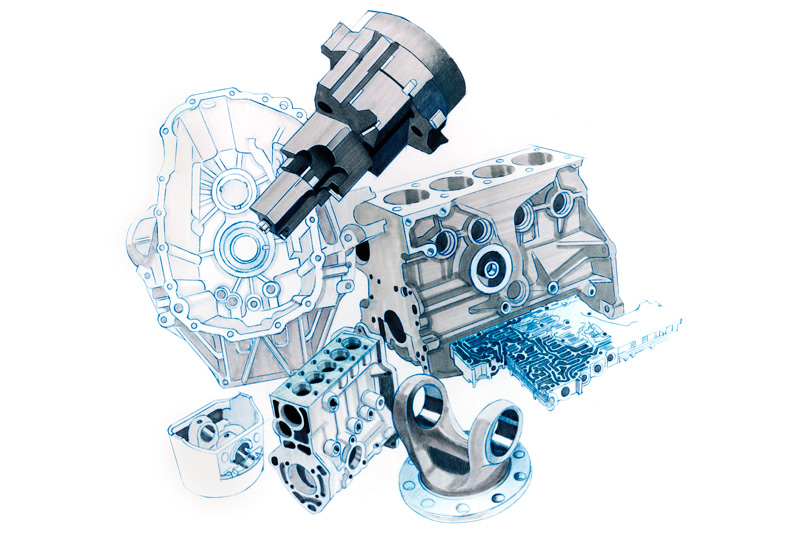

Nach und nach wurden die Reibahlen so weiterentwickelt, dass sie sich für die industrielle Großserienfertigung eigneten. Die Beschichtung von Wendeschneidplatten spielte dabei ebenso eine Rolle wie die Verwendung des Werkstoffs PKD für die Führungsleisten. Mit den Werkzeugen fasste MAPAL vor allem in der Automobilindustrie Fuß, wo die Fertigungstechnik von starren Transferstraßen auf flexible Bearbeitungszentren umgestellt wurde.

Parallel zu den technischen Verbesserungen baute MAPAL sein Vertriebskonzept um und setzte auf maximale Kundennähe. Freie Handelsvertreter wurden durch eigene technische Berater ersetzt, deren Aufgabe es war, Kunden bei der Auslegung der Werkzeuge zu beraten und im Einsatz zu unterstützen. In der Automobilindustrie wurde die Zusammenarbeit so eng, dass die Berater sogar an der Entwicklung von neuen Motoren mitwirkten, indem sie denkbare feinmechanische Bearbeitungsmöglichkeiten früh in den Konstruktionsprozess einbrachten. Sie verkauften nicht einfach Werkzeuge, sondern Lösungen.

Vom Mittelständler zum Global Player

To expand its product and service portfolio, which also followed customer requirements, MAPAL acquired specialist companies in Germany. WWS in Pforzheim expanded MAPAL’s offer to include PCD tools with brazed blades for high-speed machining, particularly of aluminium, thus covering a segment that was becoming more and more important to customers. Solid carbide drills and milling tools were added to the range courtesy of Miller in Altenstadt. As drilling from solid is the production step prior to reaming, this made a perfect addition to MAPAL’s portfolio. Weisskopf from Meiningen strengthened the solid carbide segment further.

The purchase of the long-standing Winterlingen-based company August Beck secured MAPAL’s position as a leading manufacturer of reamers. Robert Strom and ISOTOOL added ISO and actuating tools to the portfolio. In 2015, the two companies were rebranded MAPAL ITS, which focuses on complex special tools with actuating mechanisms in Eppingen. Clamping tools from WTE in Ehrenfriedersdorf completed the product range. MAPAL made further strategic investments overseas.

Transformation in full swing

There was also a strategic expansion of customer segments beyond the automotive industry, which had been a guarantee of growth over decades. MAPAL now also focuses on the aerospace, fluid power technology, and die and mould segments. Digital solutions are provided by c-Com since its founding in 2017. The start-up has been merged into the MAPAL Group and primarily assists with tool management services. The company takes all aspects of sustainable management into account with an environmental management system – with many individual measures in production and administration at all sites making their contribution.

Dr Jochen Kress initiated the transformation of MAPAL into a process-driven, global organisation. Structures and processes are being adapted to the size the company has reached; decision-making processes are being streamlined and accelerated. The reorganisation on management level at headquarters in Aalen is based on core processes and areas of focus. The structural, organisational and cultural changes that Dr Jochen Kress initiated will shape the company in the long term and endure long beyond the anniversary year 2025.

As it celebrates its 75th anniversary, the MAPAL Group is resolutely focussed on the future. With investments in new technologies, digitalisation and in the targeted development of capabilities, the company is strengthening its position in key sectors and accelerating its efforts to engage with the market and its customers. This is reflected, for instance, in the activities in the dynamically developing Aerospace segment: MAPAL has pooled its expertise in the field of aircraft final assembly in the Global Organisation for Assembly (GOA) department, founded in 2024 – a decisive step to serve global customers faster and in a more targeted manner. The integration of the subsidiary c-Com and acquisition of the Italian X-Pro S.r.l., a specialist in turnkey projects and clamping fixtures, also highlight the company’s commitment to actively shaping technological developments and fully meeting customer requirements.

Contact

Mathias Ostertag Public Relations mathias.ostertag@mapal.com Phone: +49 7361 585 3566