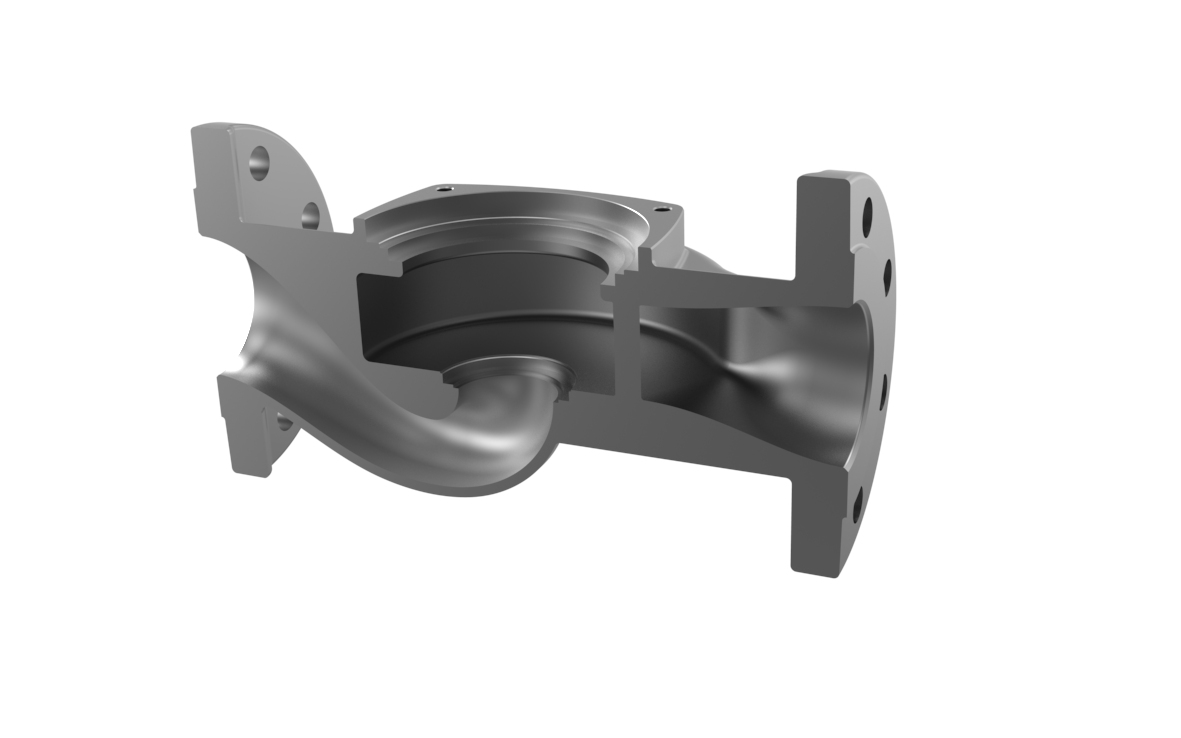

Corpo pompa di circolazione

Corpo pompa in EN-GJL-250 / 1.4301 (V2A)

Situazione di partenza del cliente

- Processo non flessibile: unità a cursore piano su linea di trasferimento

- Lunghi tempi non produttivi durante il cambio degli utensili e dei prodotti causano fermi macchina

- Requisito: tempi di ciclo e cambio prodotto ridotti

- Necessità di grande flessibilità per la lavorazione di tutte le varianti di componenti su un’unica macchina

Particolarità della soluzione

- Possibilità di cambio utensile automatico

- Regolazione utensili ininfluente sul tempo di utilizzo grazie a utensili gemelli

- La flessibilità del processo consente la preregolazione dell’utensile

- Rapido cambio utensile

- Possibilità di usare utensili standard (ad es. punte o frese) nello stesso mandrino

- Bassi costi del materiale da taglio grazie alla tecnologia con inserti a fissaggio meccanico

- Riduzione dei tempi di ciclo grazie a z=2 rispetto alla lavorazione su tornio

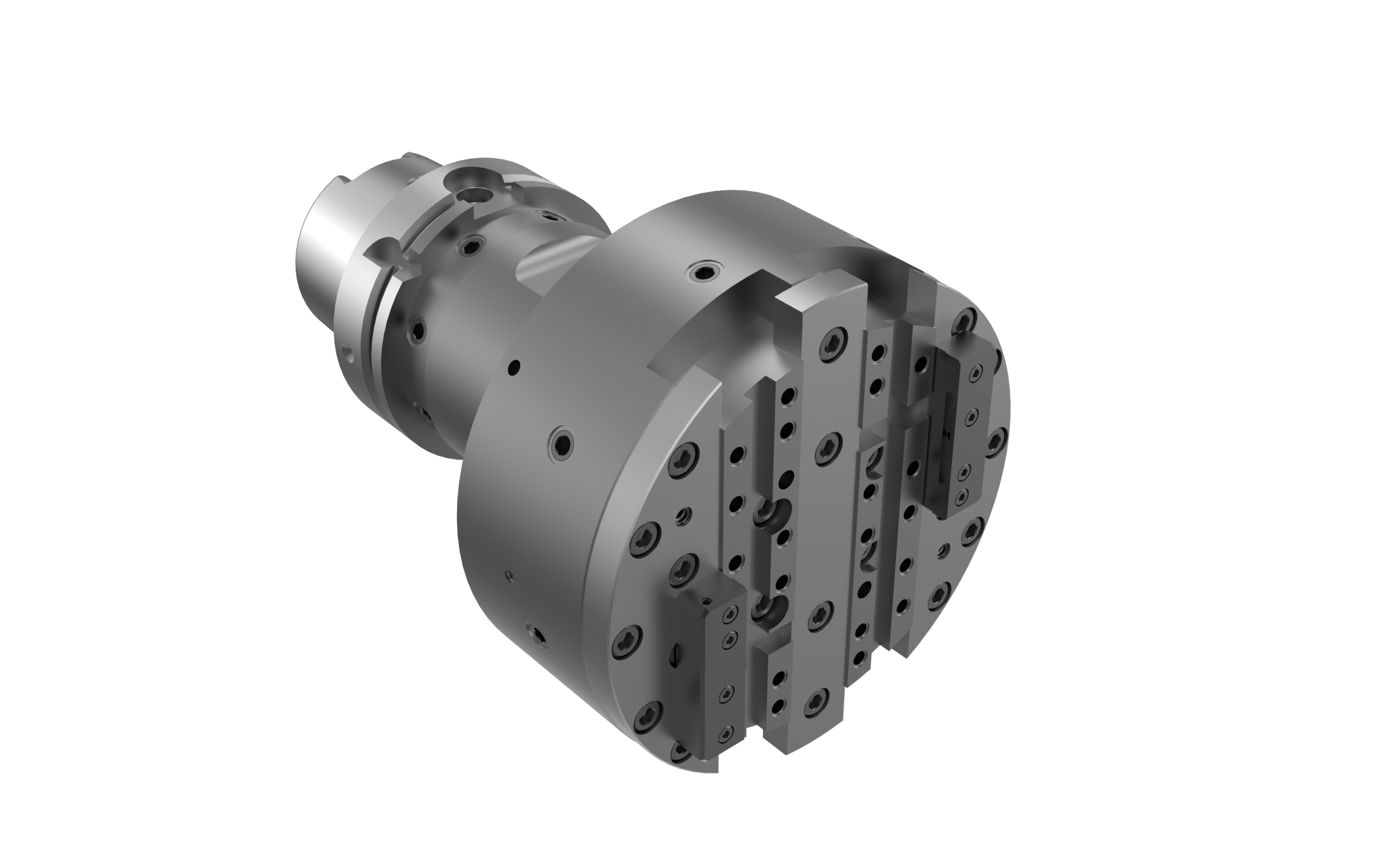

Punti salienti dell’utensile

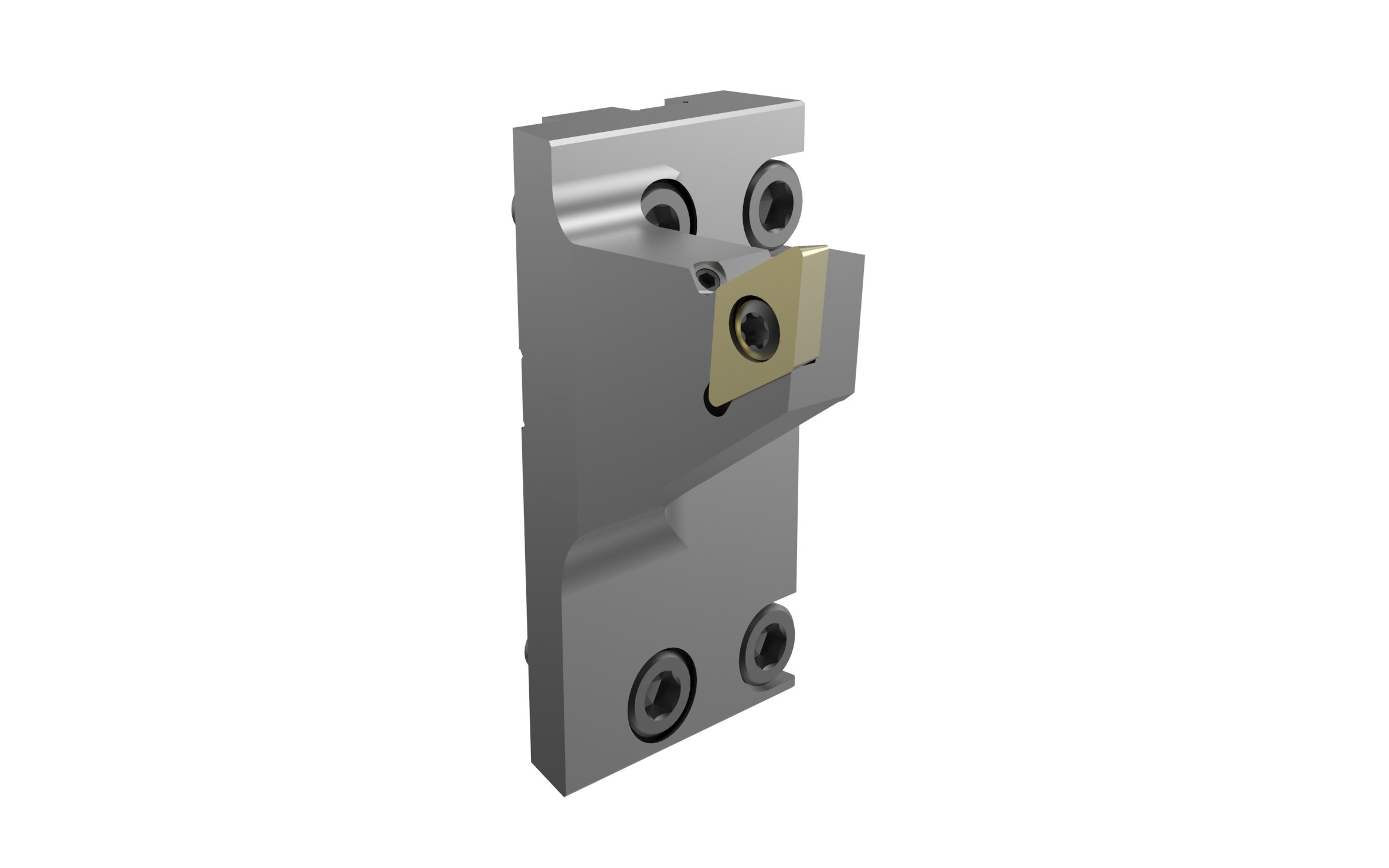

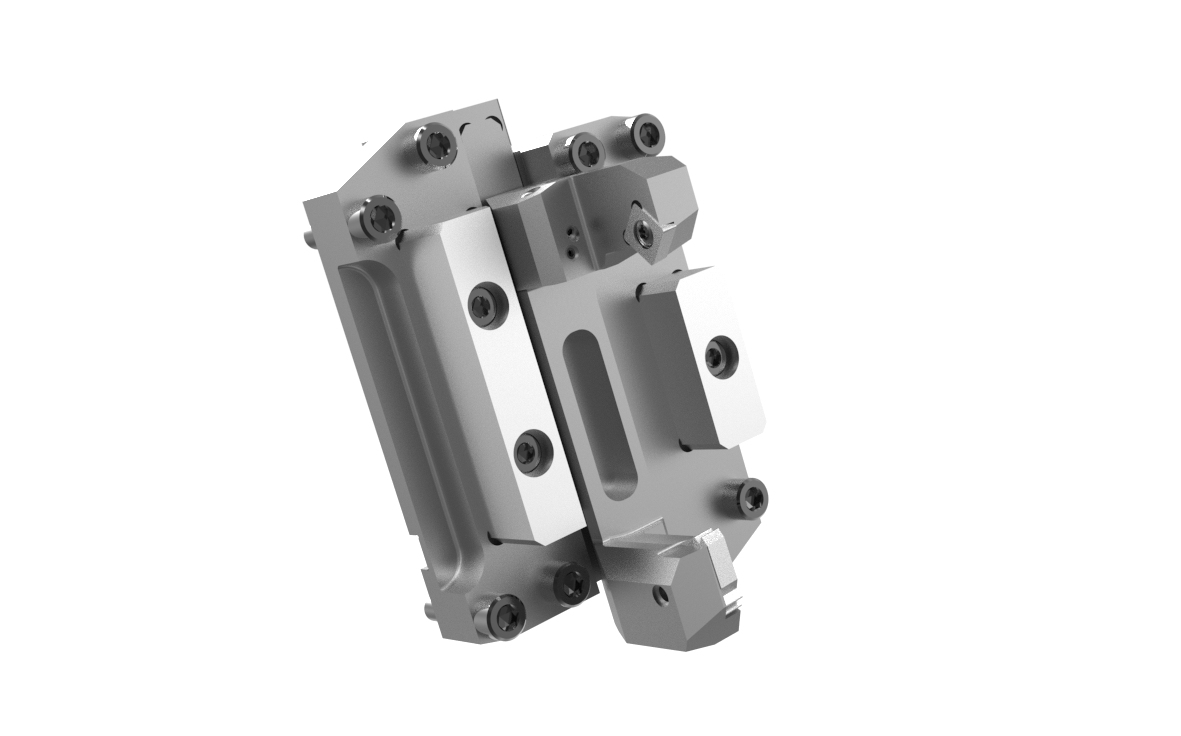

Utensile di comando per sistemi con asse U

- Utensili flessibili consentono di coprire tutte le varianti di componenti con solo quattro tipologie

- La semplice sostituzione degli inserti a fissaggio meccanico consente la lavorazione di diversi materiali

- Massima flessibilità grazie all’innesto intercambiabile HSK e deposito in magazzino utensili

- Versione come cursore singolo e doppio

- Possibilità di utilizzare utensili gemelli

Contorno interno + sfacciatura

Contorno esterno + lavorazione di filetti

![DOWNTIMES [MIN.] FOR PRODUCT CHANGES](/medias/sys_master/root/he9/h05/9687965368350/EN__Diagramme/EN-Diagramme.jpg)

Vantaggi

- Riduzione dei tempi di inattività per la sostituzione di prodotti e taglienti

- Elevato risparmio sui costi del processo in serie

- Necessità di un solo tipo di testa a sfacciare con utensili intercambiabili per l’intera gamma di prodotti

- Attuabile su tutte le macchine con asse U o azionamenti Tooltronic®

- Possibilità di lavorazione completa su una sola macchina in un unico serraggio

![DOWNTIMES [MIN.] FOR CUTTING EDGE CHANGES](/medias/sys_master/root/ha8/h09/9687965499422/EN__Diagramme2/EN-Diagramme2.jpg)