Raccords

Solutions d'application grâce à la technologie de modulation

Raccords en CuSi4Zn9MnP

Situation initiale du client

- Usinage sur machine à transfert rotatif

- Exigence : Temps de cycle réduit et productivité maximale dans le processus de fabrication en grande série

- Le système d'outil doit pouvoir être préréglé en dehors de la machine et adapté de manière flexible aux variantes de pièces

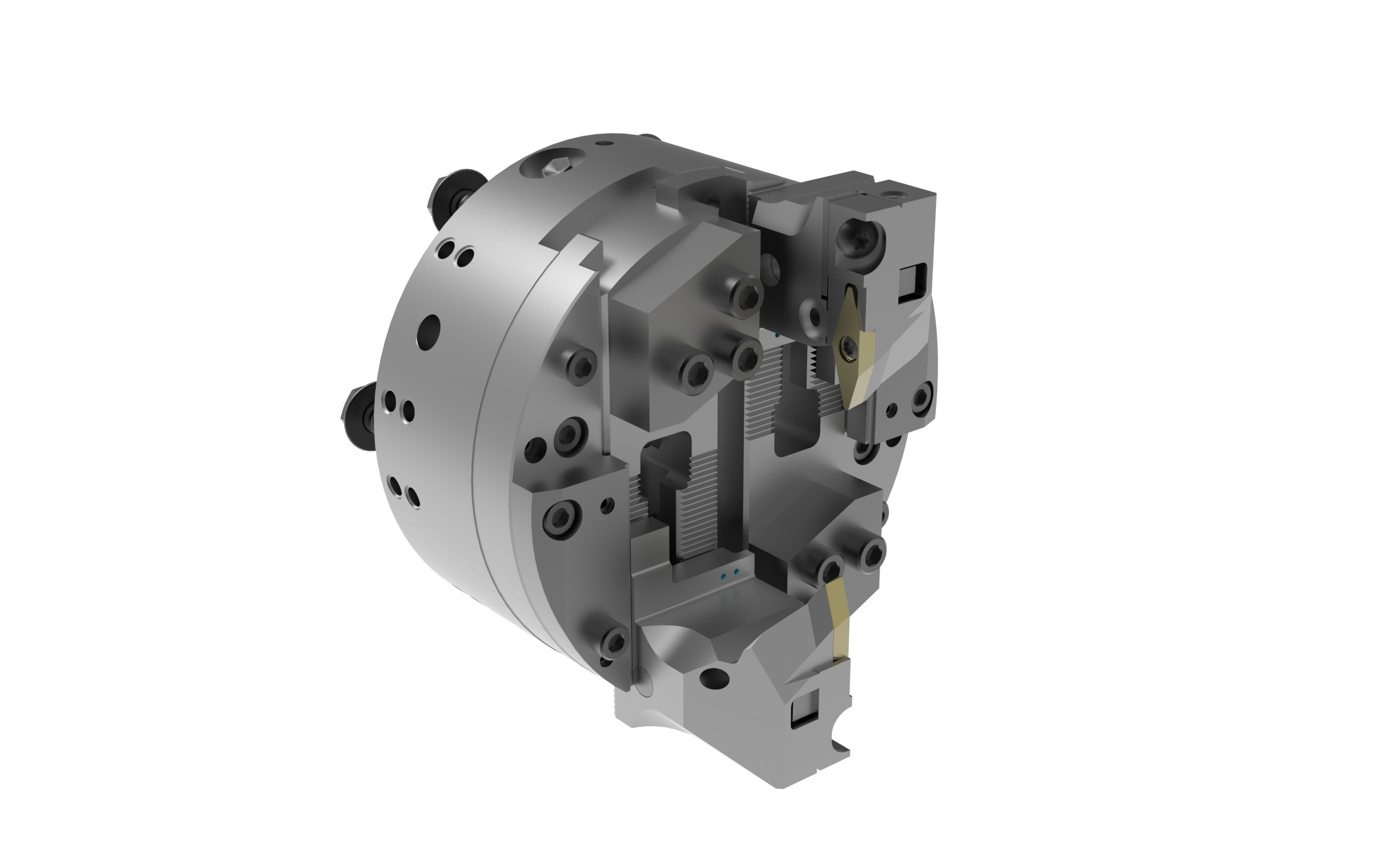

Particularités de la solution

- Outils coupants avec adaptateur préréglables sans arrêt de la machine

- Interface VTS

- Changement d'outil coupant simple et rapide

- Pas de montage/positionnement incorrect possible lors du changement d'outil coupant

- Technologie de plaquettes amovibles permettant de réduire le coût des matériaux de coupe

- Les matériaux de coupe PCD garantissent une rentabilité maximale dans le processus de fabrication en série

Points forts de l'outil

- Interface VTS pour changement simple et rapide des outils coupants

- Double tiroir z=2 pour des temps de cycle réduits et une compensation complète du déséquilibre

- Arrosage optimal directement sur l'outil coupant

![CYCLE TIMES [MIN.]](/medias/sys_master/root/h78/h10/9687965696030/EN__Diagramme4/EN-Diagramme4.jpg)

Avantages

- Productivité maximale, car toutes les tâches d'usinage (profils, filetages, etc.) peuvent être réalisées efficacement grâce à la technologie de modulation MAPAL

- Réduction significative du temps de cycle de 35 % grâce aux solutions d'outils à double arête de coupe

- Réduction des temps d'arrêt lors du changement de produit et d'arête de coupe dans le processus de fabrication en série grâce à l'interface VTS

- Un seul type de tête de dressage avec outils coupants interchangeables est nécessaire pour l'ensemble de la gamme de produits

- Flexibilité maximale concernant la réglementation REACH et les exigences fluctuantes relatives aux pièces