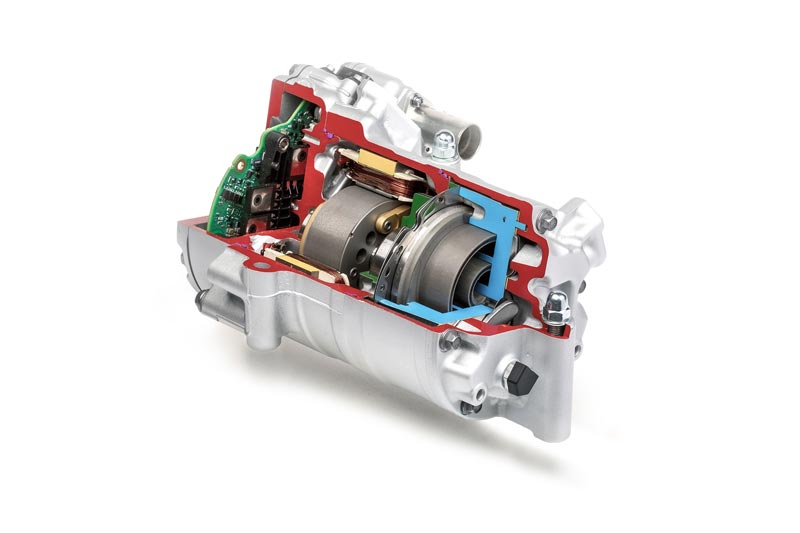

Pequena carcaça do motor elétrico

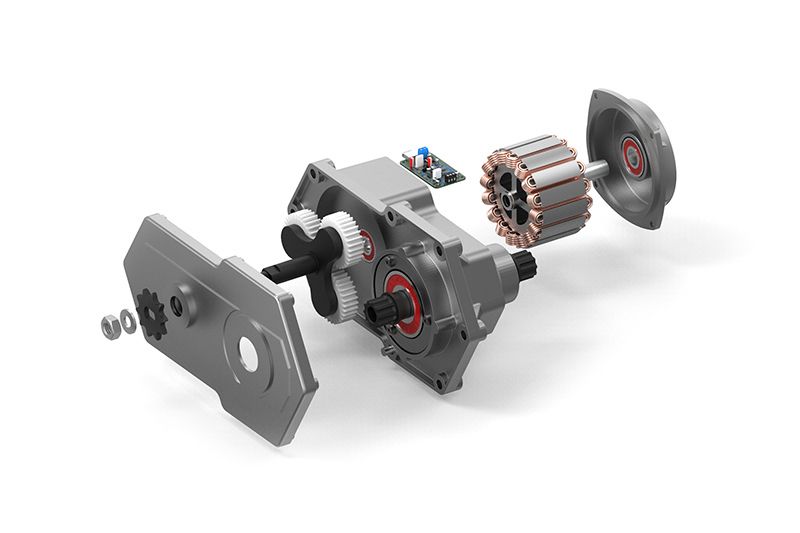

Exemplo bicicleta elétrica acionamento

A mobilidade elétrica há muito tempo encontrou o seu lugar na vida cotidiana. O público em geral foi apresentado pela primeira vez aos acionamentos elétricos em bicicletas. As carcaças do motor, entre outras coisas, representam um desafio em sua produção – elas devem ser pequenas e leves e, ao mesmo tempo, altamente precisas.

Nas últimas décadas, a MAPAL ganhou uma vasta experiência na usinagem de pequenas carcaças de motor feitas de alumínio e magnésio, por exemplo, caixas para motosserras, ciclomotores ou cortadores de grama. No entanto, os requisitos de precisão aumentaram mais uma vez com a eletrificação.

CARACTERÍSTICAS

- Duas partes ou três partes (carcaça e tampa)

- Carcaças fundidas feitas de alumínio ou magnésio

- Componentes frágeis de parede fina (suscetíveis a vibração)

- Trajetos de contorno com vários estágios

- Os requisitos geométricos e dimensionais são elevados (tolerâncias de forma, de funcionamento e de posição)

EXIGÊNCIAS DA USINAGEM

- Circularidade < 0,01 mm

- Tolerância de diâmetro IT7

- Rugosidade média Rz < 10 μm

A ferramenta PCD processa furos de rolamento e posicionamento na carcaça de magnésio

Na usinagem dos furos de rolamento e posicionamento em uma carcaça específica de magnésio, as fortes vibrações representam um desafio especial, pois o componente tem paredes extremamente finas na área do terceiro furo do rolamento. A ferramenta deve remover 0,6 mm a 1 mm de material dos furos pré-fabricados.

Devem ser respeitados os seguintes parâmetros:

- Circularidade < 0,01 mm

- Tolerância de diâmetro IT7

- Rugosidade média Rz < 10 µm

A MAPAL utiliza uma complexa ferramenta combinada de PCD de múltiplos estágios para essa finalidade, que usina os três furos de rolamento e o furo de posicionamento do assento do rolamento em um único disparo - com confiabilidade de processo dentro das tolerâncias exigidas.

A ferramenta funciona com os seguintes dados de corte:

- Rotação 8.000 rpm

- Velocidade de avanço 3.200 a 4.800 mm/min

- Avanço 0,1 mm a 0,15 mm

Furação e fresamento em uma única ferramenta

Outra ferramenta combina operações de fresamento e perfuração em uma carcaça de magnésio. Enquanto os estágios de perfuração usinam o furo de rolamento e o furo de posicionamento, um estágio de fresamento é usado para produzir a ranhura de vedação. Ao usar essa ferramenta, também foi importante evitar vibrações e manter a pressão de corte baixa. Os especialistas em ferramentas conseguiram isso otimizando o número de dentes e a geometria do estágio de fresamento. Isso também evita cavacos na ranhura.

Dados de corte do estágio de fresamento:

- Rotação 8.000 rpm

- Velocidade de avanço 7.200 mm/min

- Avanço 0,15 mm

A MAPAL oferece um pacote completo para a usinagem de pequenas carcaças de alumínio ou magnésio.

Em primeiro lugar, as ferramentas de PCD e de metal duro integral são ideais para a usinagem de ambos os materiais. Dependendo dos requisitos e da complexidade, a MAPAL projetará o melhor conceito, incluindo todas as ferramentas e mandris. Ferramentas combinadas, cada uma cobrindo várias etapas de trabalho, tornam o processo mais econômico.